Copolymerized polystyrene fluorescent microsphere and preparation method thereof

A technology of fluorescent microspheres and polystyrene, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of fluorescence effect attenuation, environmental pollution, active site occupation, etc., and achieve stable fluorescence performance, good monodispersity, Good fluorescent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Styrene refining:

[0030] Take an appropriate amount of basic alumina and put it in a chromatography column, and 100 mL of styrene is used to remove the polymerization inhibitor in the chromatography column. Put the treated styrene into a dry reagent bottle, and add an appropriate amount of molecular sieve to remove possible residual moisture. Styrene was stored in a 4°C refrigerator.

[0031] 2) Azobisisobutyronitrile purification:

Embodiment 2

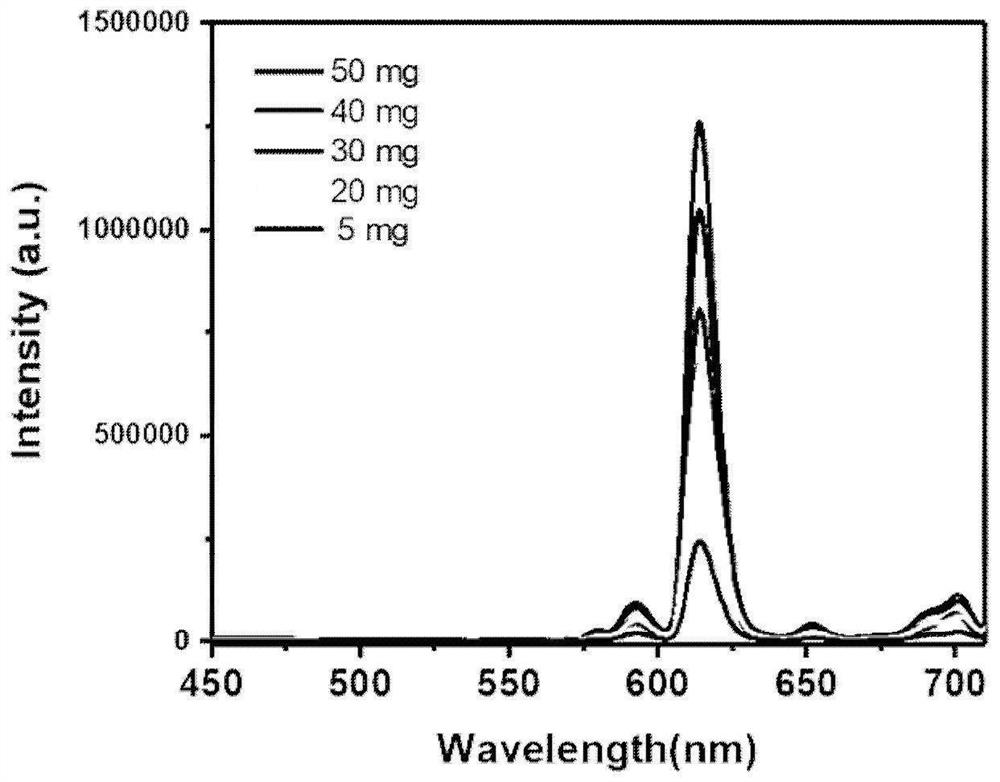

[0033] The invention provides a copolymerized fluorescent microsphere and a preparation method thereof. The preparation raw materials include: 86.71% of styrene, 1.73% of azobisisobutyronitrile (AIBN), 7.95% of polyvinylpyrrolidone (PVP), anhydrous ethanol: Distilled water = 9:1, rare earth europium complex (Eu(BFA) 3 (Aphen)) 3.61%, the preparation method comprises the following steps:

[0034] 1) Add a certain amount of PVP, anhydrous ethanol and distilled water to the three-necked flask, stir evenly, pass nitrogen to empty for 30min, slowly add AIBN-dissolved anhydrous ethanol solution dropwise, continue stirring and then add styrene dropwise.

[0035] 2) Then slowly dropwise add Eu(BFA) dissolved in it 3 (Aphen) complex in anhydrous ethanol solution, the process has been N 2 Atmosphere protection, after stirring evenly, heated to 70 ℃.

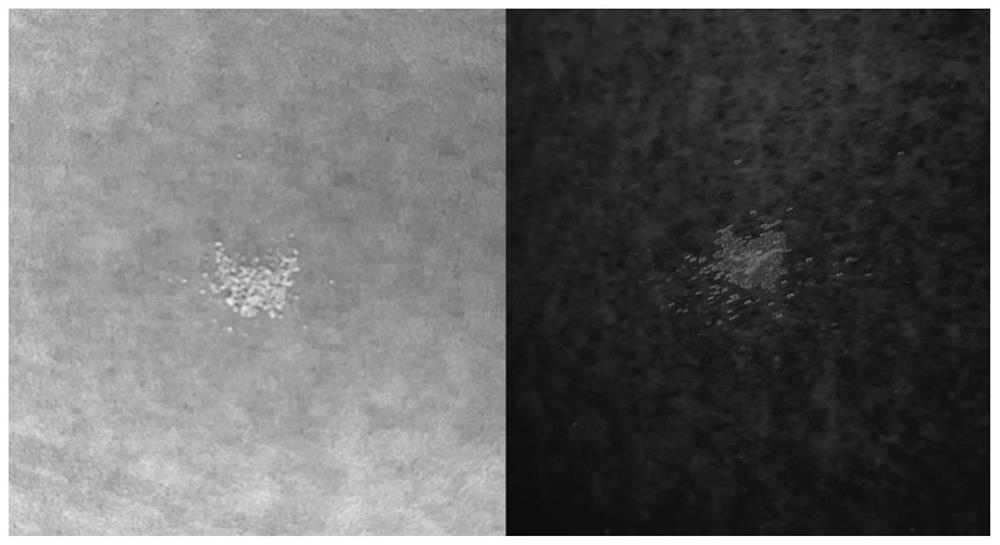

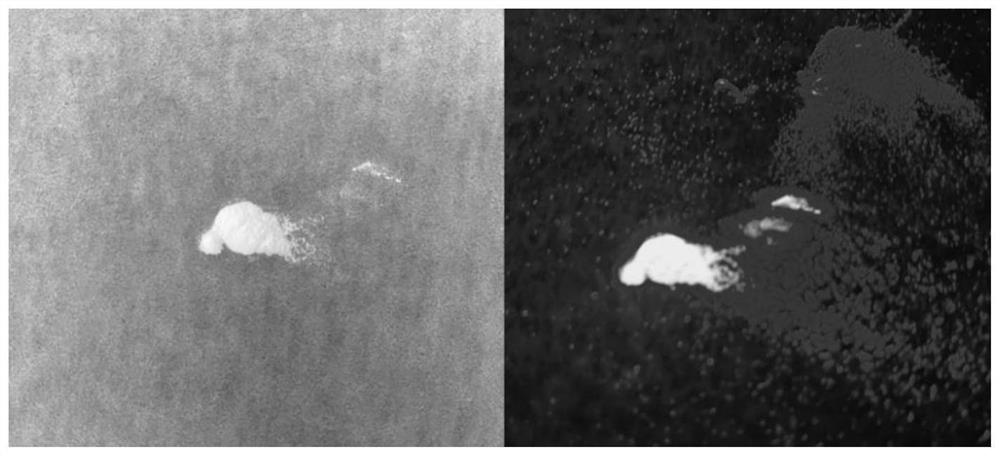

[0036] 3) Keep a certain stirring speed and react for 12h. A milky white liquid was obtained, the reaction was stopped by centrifugat...

Embodiment 3

[0040] The preparation raw materials include: 87.34% styrene, 1.75% azobisisobutyronitrile (AIBN), 8.01% polyvinylpyrrolidone (PVP), absolute ethanol:distilled water=9:1, rare earth europium complex (Eu(BFA) 3 (Aphen)) 2.91%, the preparation method comprises the following steps:

[0041] 1) Add a certain amount of PVP, anhydrous ethanol and distilled water to the three-necked flask, stir evenly, pass nitrogen to empty for 30min, slowly add AIBN-dissolved anhydrous ethanol solution dropwise, continue stirring and then add styrene dropwise.

[0042] 2) Then slowly dropwise add Eu(BFA) dissolved in it 3 (Aphen) complex in anhydrous ethanol solution, the process has been N 2 Atmosphere protection, after stirring evenly, heat to 70 ℃

[0043] 3) Keep a certain stirring speed and react for 12h. A milky white liquid was obtained, the reaction was stopped and centrifuged with a centrifuge, the supernatant was discarded, washed with distilled water and then centrifuged, washed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com