Biodegradable agricultural mulching film modified material and preparation method thereof

A technology for modifying materials and agricultural mulch, applied in plant protection cover, climate change adaptation, etc., can solve problems such as prolonging the induction period of degraded mulch, and achieve the effect of reducing the surface energy of the material, improving the effect, and improving the water vapor barrier performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

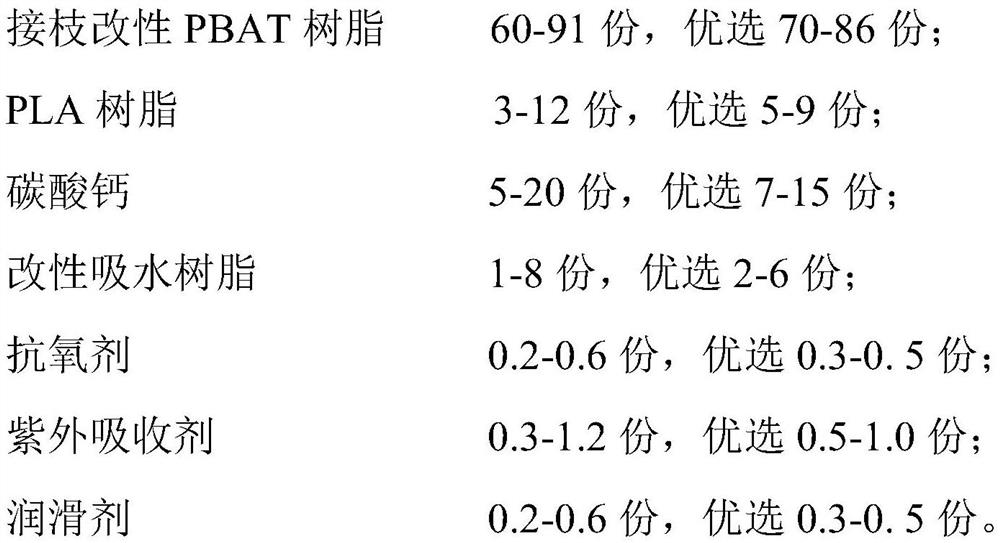

Method used

Image

Examples

Embodiment 1

[0056] (1) First, according to the ratio of 95:5:0.2, weigh 86.45kg of PBAT resin, 4.55kg of oxidized polyethylene wax (TLZJ-4), and 0.18kg of chain extender (HDI), respectively. The twin-screw extruder performs melt blending and grafting to obtain graft-modified PBAT resin.

[0057] (2) First, weigh 0.1kg of antiseptic and add it into 0.4kg of water to form a uniform solution, then spray the above solution in 0.5kg of water-absorbent resin powder, stir evenly for 5 minutes, and obtain 1kg of modified water-absorbent resin particles;

[0058] (3) above-mentioned 1kg modified water-absorbing resin and 91kg graft modified PBAT resin and 3kg PLA resin, 5kg calcium carbonate and 0.2kg antioxidant, 0.3kg ultraviolet absorber, 0.2kg lubricant are added in MIXER agitator, 600rpm Stir at a stirring speed of / min for 4 minutes and mix evenly, add it to the twin-screw extrusion through the main feeding method, and extract the water in the material by vacuuming at the end of the extruder...

Embodiment 2

[0060] (1) First, according to the ratio of 93:7:0.3, weigh 79.98kg of PBAT resin, 6.02kg of oxidized polyethylene wax (TLZJ-4), and 0.26kg of chain extender (HDI). The twin-screw extruder performs melt blending and grafting to obtain graft-modified PBAT resin.

[0061] (2) first weigh 0.2kg of preservative and add it to 0.8kg of water to form a uniform solution, then spray the above solution in 1.0kg of water-absorbent resin powder, stir evenly and stand still for 5min to obtain 2kg of modified water-absorbent resin particles;

[0062] (3) above-mentioned 2kg modified water-absorbing resin and 86kg graft modified PBAT resin and 5kg PLA resin, 7kg calcium carbonate and 0.3kg antioxidant, 0.5kg ultraviolet absorber, 0.3kg lubricant are added in the MIXER stirrer, 600rpm Stir at a stirring speed of / min for 4 minutes and mix evenly, add it to the twin-screw extrusion through the main feeding method, and extract the water in the material by vacuuming at the end of the extruder, t...

Embodiment 3

[0064] (1) First, according to the ratio of 91:9:0.5, weigh 71.89kg of PBAT resin, 7.11kg of oxidized polyethylene wax (TLZJ-0), and 0.40kg of chain extender (epoxy chain extender), and mix them with a MIXER mixer After homogenization, the graft-modified PBAT resin is obtained by melt blending and grafting through a twin-screw extruder.

[0065] (2) first weigh 0.3kg of antiseptic and add it to 1.2kg of water to form a uniform solution, then spray the above solution evenly in 2.5kg of water-absorbent resin powder, stir evenly and stand still for 5min to obtain 4kg of modified water-absorbent resin particles;

[0066] (3) above-mentioned 4kg modified water-absorbing resin and 79kg graft modified PBAT resin and 7kg PLA resin, 10kg calcium carbonate and 0.4kg antioxidant, 0.8kg ultraviolet absorber, 0.4kg lubricant are added in MIXER agitator, 600rpm Stir at a stirring speed of / min for 4 minutes and mix evenly, add it to the twin-screw extrusion through the main feeding method, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com