Insulating material as well as preparation method and application thereof

A technology of insulating materials and composite slurry, applied in the direction of additive processing, etc., can solve the problems of low curing thickness, interlayer peeling, low quality, etc., and achieve the effect of high mechanical strength, fast curing speed and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

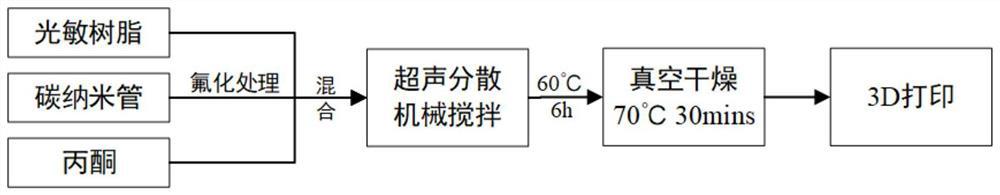

[0053] see figure 1 , an insulating material preparation method of the present invention, comprising the following steps:

[0054] S1, carry out plasma fluorination treatment to the carbon nanotubes of drying, obtain nonlinear conductivity fluorinated carbon nanotubes, add acetone and photosensitive resin successively to nonlinear conductivity fluorinated carbon nanotubes, and stir with a medicine spoon , to obtain mixture A;

[0055] The nonlinear conductivity photosensitive resin-based composite paste is prepared from carbon nanotubes, photosensitive resin and acetone treated by plasma fluorination, and the mass ratio of the nonlinear conductivity fluorinated carbon nanotubes to the photosensitive resin is (0.3-0.6 ): 100; the mass ratio of acetone to the photosensitive resin matrix is 1: (3-5).

[0056] Among them, the fluorine content of the fluorinated carbon nanotubes is controlled by the time of the plasma fluorination treatment.

[0057] Carbon nanotubes are one o...

Embodiment 1

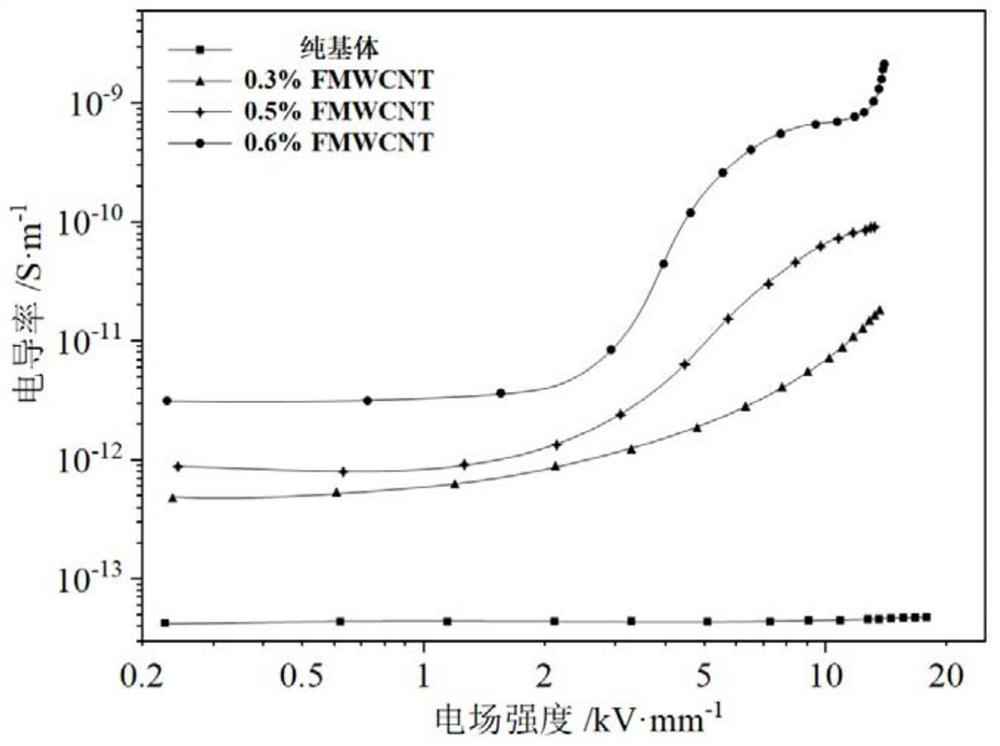

[0065] The multi-walled carbon nanotubes are dried, and the dried multi-walled carbon nanotubes are subjected to plasma fluorination treatment for 20 minutes. 1.6 grams of acetone, finally add 8 grams of photosensitive resin, stir with a spatula to prepare mixtures with mass fractions of 0%, 0.3%, 0.5%, and 0.6%, respectively, and then ultrasonically treat the mixture at a water temperature of 60 °C, make it evenly mixed;

[0066] After 5 hours, take out the mixture after ultrasonic stirring, put it into a vacuum drying oven, and treat it at 75 °C for 10 minutes. After 10 minutes, take out a part of the mixture and pour it into a silica gel mold. The wavelength is 405 nm and the power is 30 mW / cm. 2 The samples were made by curing under the ultraviolet light for 20 minutes, and the variation curve of the conductivity with the field strength of the samples with different mass fractions was measured.

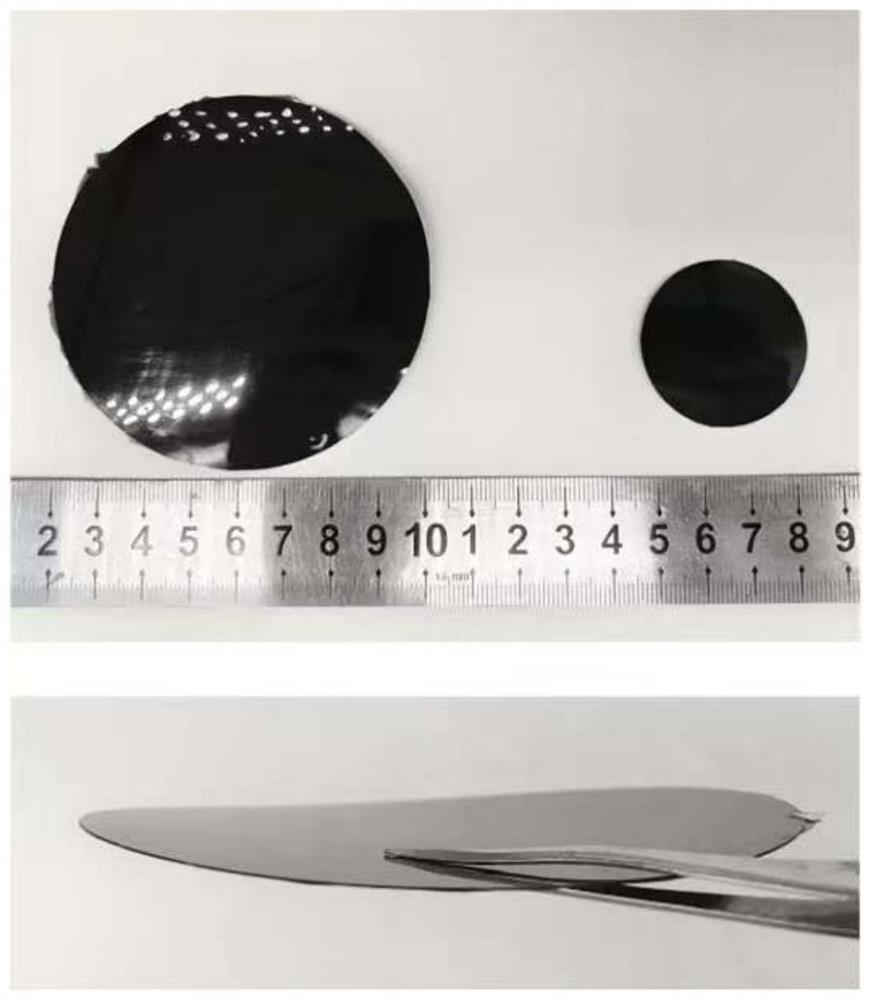

[0067] The remaining part of the mixture was poured into a 5mm deep Teflon m...

Embodiment 2

[0070] The multi-walled carbon nanotubes were dried, and the dried multi-walled carbon nanotubes were subjected to plasma fluorination treatment for 10 minutes. 1.6 grams of acetone, finally add 8 grams of photosensitive resin, stir with a spatula to prepare mixtures with mass fractions of 0%, 0.3%, 0.5%, and 0.6%, respectively, and then ultrasonically treat the mixture at a water temperature of 40 °C, make it evenly mixed;

[0071] After 7 hours, the ultrasonically stirred mixture was taken out, put into a vacuum drying oven, and treated at 60 °C for 40 minutes, and then a part of the mixture was taken out and poured into a silica gel mold. The wavelength was 405 nm and the power was 120 mW / cm. 2 The samples were made by curing under high UV light for 5 minutes, and the variation curve of the conductivity with the field strength of the samples with different mass fractions was measured;

[0072] The remaining part of the mixture was poured into a 5mm deep PTFE mold, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com