MXene-based conductive self-cleaning composite fabric for electromagnetic shielding and preparation method of MXene-based conductive self-cleaning composite fabric

A composite fabric, electromagnetic shielding technology, used in plant fibers, textiles and papermaking, fiber processing and other directions, can solve the problems of poor electromagnetic shielding performance, poor mechanical properties, moisture resistance, etc., to achieve good stability, excellent bonding force, easily oxidized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Dip coating with conductive coating

[0033] a) Fabric surface pretreatment

[0034] Before dip coating, the surface pretreatment of polyester (PET) fabric was carried out by alkaline solution method. The specific steps were as follows: Immerse a certain size of PET fabric (2.5cm×2.5cm) in NaOH solution (10mg / mL) and reacted at 80°C for 2 hours, then taken out and washed with deionized water for several times until neutral, and put it into a vacuum oven (40°C) to dry for use.

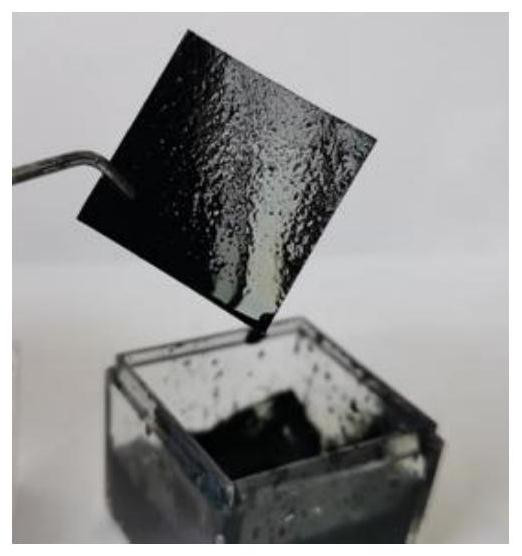

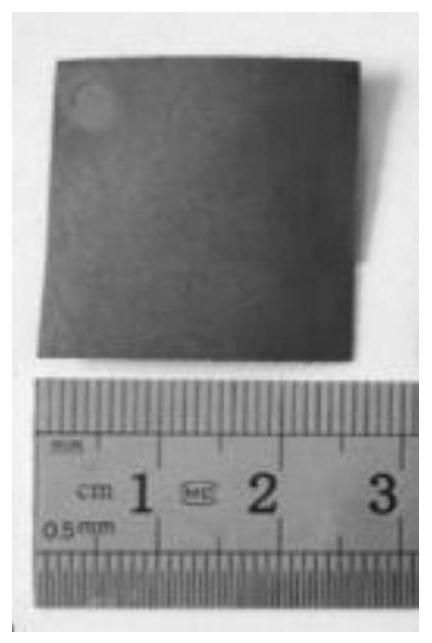

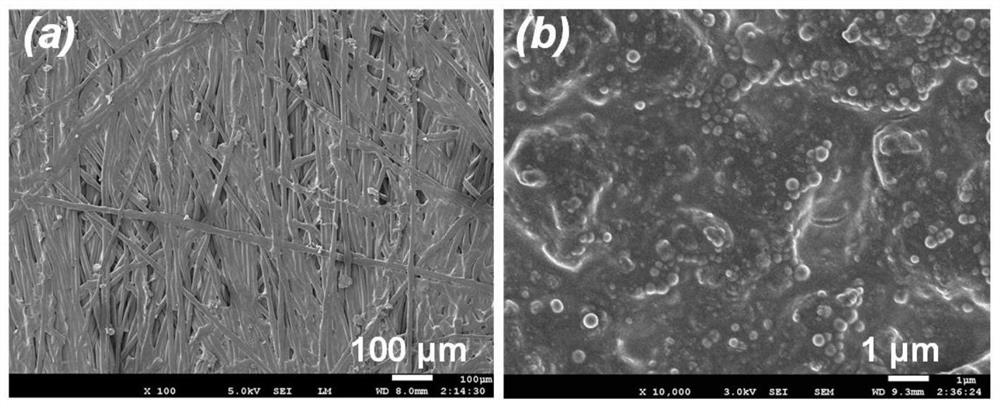

[0035] b) Fabric dip coating modification

[0036] Ti 3 C 2 T x The dispersions of MXene and multi-walled carbon nanotubes (MWCNTs) were blended to prepare homogeneous aqueous dispersions of both (total concentration of 15 mg / mL, Ti 3 C 2 T x The mass ratio to MWCNT is 5:2), and the mixing conditions are: magnetic stirring (600rpm / 40min) and ultrasonic (40KHz / 200W / 40min). The pretreated polyester fabric was immersed in the MXene / MWCNT uniform dispersion for 5 min ( figure 1 ); then ta...

Embodiment 2

[0046] In this example, the preparation method of the conductive coating is similar to that of Example 1, the difference is that cotton fabric is used as the base fabric; MXene / SWCNT is used as the conductive modification component, the mass ratio of the two is 10:3, and the total concentration It is 10mg / mL (mixing treatment conditions are magnetic force 300rpm / 30min, ultrasonic 40KHz / 200W / 20min); dip coating times are 8 times (drying conditions - normal pressure 80℃ / 30min); silicone rubber vulcanization reaction conditions are normal pressure oven 70 ℃ / 3h. The conductive self-cleaning composite fabric prepared in this example also exhibits ideal superhydrophobicity (water contact angle 151.5°), excellent electrical conductivity and electromagnetic shielding performance, excellent mechanical stability and acid corrosion resistance (as shown in Table 1). ).

Embodiment 3

[0048] In this example, the preparation method of the conductive coating is similar to that of Example 1, except that nylon is used as the base fabric; MXene / GO (graphene oxide) is used as the conductive modification component, and the mass ratio of the two is 10:1 , the total concentration is 7mg / mL (the mixing treatment conditions are magnetic force 100rpm / 40min, ultrasonic 40KHz / 200W / 30min); the coating process is spraying, the nozzle diameter is 0.3mm, the distance between the airbrush and the fabric is 5cm, and the airbrush moving speed is 3cm / s, the airbrush adopts one-way spraying, drying conditions - vacuum 70℃ / 30min, spraying times is 7 times; the silicone rubber is condensed room temperature vulcanized silicone rubber (hydroxyl-terminated polysiloxane / ethyl orthosilicate) / Organotin catalyst, n-heptane as solvent, concentration of 1 wt%), and the vulcanization reaction condition is atmospheric pressure oven 60°C / 4h. The conductive self-cleaning composite fabric prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com