Improved multi-scale high-temperature speckle preparation method

A multi-scale and speckle technology, applied in the field of photomechanics, can solve problems such as difficult quality control, surface damage of test pieces, and small application range, and achieve the effects of enhancing image contrast, strong high temperature resistance, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

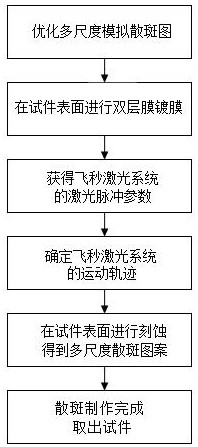

[0035] The improved multi-scale high-temperature speckle preparation method proposed by the present invention, as shown in Figure 1, includes the following steps:

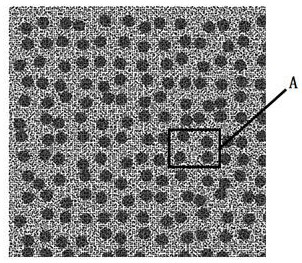

[0036] Step 1. Determine and optimize the characteristic parameters of the digital speckle field to generate an optimized multi-scale simulated speckle image. The characteristic parameters of the digital speckle field include a speckle diameter D, a coverage ratio c, and a randomness factor rand; and the optimized digital speckle field characteristic parameters are based on the parameters of the DIC imaging device to determine the size of the speckle diameter D at the macro and micro scales, and according to The comprehensive evaluation method of speckle quality is used to optimize the coverage rate c and the randomness factor rand; according to the optimized speckle diameter D, the coverage rate c, and the randomness factor rand, the computer software MATLAB is used to generate the optimized multi-scale simulated s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com