Preparation method and application of Mg/Al layered double hydroxide and salt activated zeolite composite adsorption material

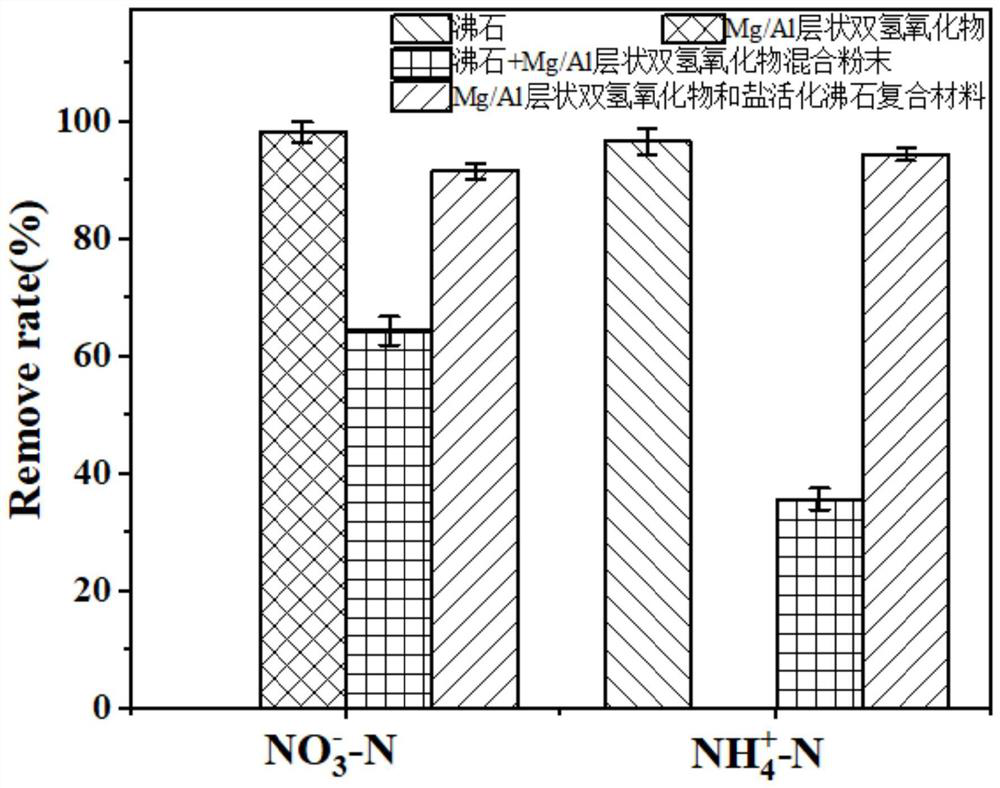

A technology of composite adsorption materials and hydroxides, applied in chemical instruments and methods, silicon compounds, chemical/physical processes, etc., can solve the problems of secondary pollution, stacking and hiding of adsorption sites, inability to adsorb ammonia nitrogen in water, etc., and achieve easy Exchange, increase the opportunity and rate of exchange, and increase the effect of ammonia nitrogen adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Mg / Al layer -like hydrogen oxide and salt activated boilestone composite adsorbing materials, including the following steps:

[0043] (1) When the natural boiler was washed with exfoliating water multiple times, grinded to the particle size of 100 meters, and the ball mill can be grinded;

[0044] (2) Place the zoom in the configured sodium chloride solution, and the concentration of the sodium chloride solution is 3 mol / L (17.53g naCl can be dissolved in 100ml of ionic water in this example, and 3mol / L NaCl solution is prepaid). The mass and volume ratio of amproof and sodium chloride solution is 1g: 10ml (in this embodiment can be 10g of zigza, 100ml of sodium chloride solution), stir 3h first, then stir up 1h, then add the same concentration to add the same concentration, then add the same concentration Sodium chloride solution, the mass and volume ratio of amproof and sodium chloride solution is 1g: 10ml (in this embodiment, 10g of zigza, 100ml of sodium chloride soluti...

Embodiment 2

[0049] Mg / Al layer -like hydrogen oxide and salt activated boilestone composite adsorbing materials, including the following steps:

[0050] (1) Washing naturally ished with exfoliating water multiple times, then grinded to the particle size of 100 meters;

[0051] (2) Place the zoom in the configuration of sodium acetate solution. The concentration of sodium acetate solution is 3 mol / L, the quality and volume ratio of the amproof and sodium acetate solution is 1g: 10ml, stir 4h first, then static for 2h, pour pour After the liquid is cleared, add the same concentration of sodium acetate solution, and continue to stir for 4h; wash the boilestone that is continuously modified with exfoliating water, and then put it in the environment of 70 ° C to get the salt activation of the boiler;

[0052] (3) Press metal ion mg 2+ / Al 3+ Moorby is 5: 1 prepaid metal salt solution, stir 40min to form an A solution; according to the quality ratio is 3: 2 to take salt activated boilite and lamina...

Embodiment 3

[0056] Mg / Al layer -like hydrogen oxide and salt activated boilestone composite adsorbing materials, including the following steps:

[0057] (1) Washing naturally ished with exfoliating water multiple times, then grinded to the particle size of 100 meters;

[0058] (2) Put the muffle in the configured ethyleine tethotate sodium solution, the concentration of the ethyleine tetrazide sodium solution is 3 mol / L, the quality and volume ratio of the amprole and ethylehthalamine sodium solution solution For 1:10, stir at 3.5h first, then stir up 1.5h, pour the clear liquid, then add the same concentration of ethyleine tetable sodium solution, continue to stir 3.5h; Ion water is washed multiple times, and then dried in the environment of 75 ° C to get salt activated boiler;

[0059] (3) Press metal ion mg 2+ / Al 3+ Moorby is 3: 1 prepaid metal salt solution, stir 35 minutes to form an A solution; according to the quality ratio is 3: 2 to take salt to activate boiletite and laminar dual -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com