Solid super acidic catalyst and its preparation method

A solid superacid and catalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems not mentioned, and achieve increased surface area, improved stability, and improved catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

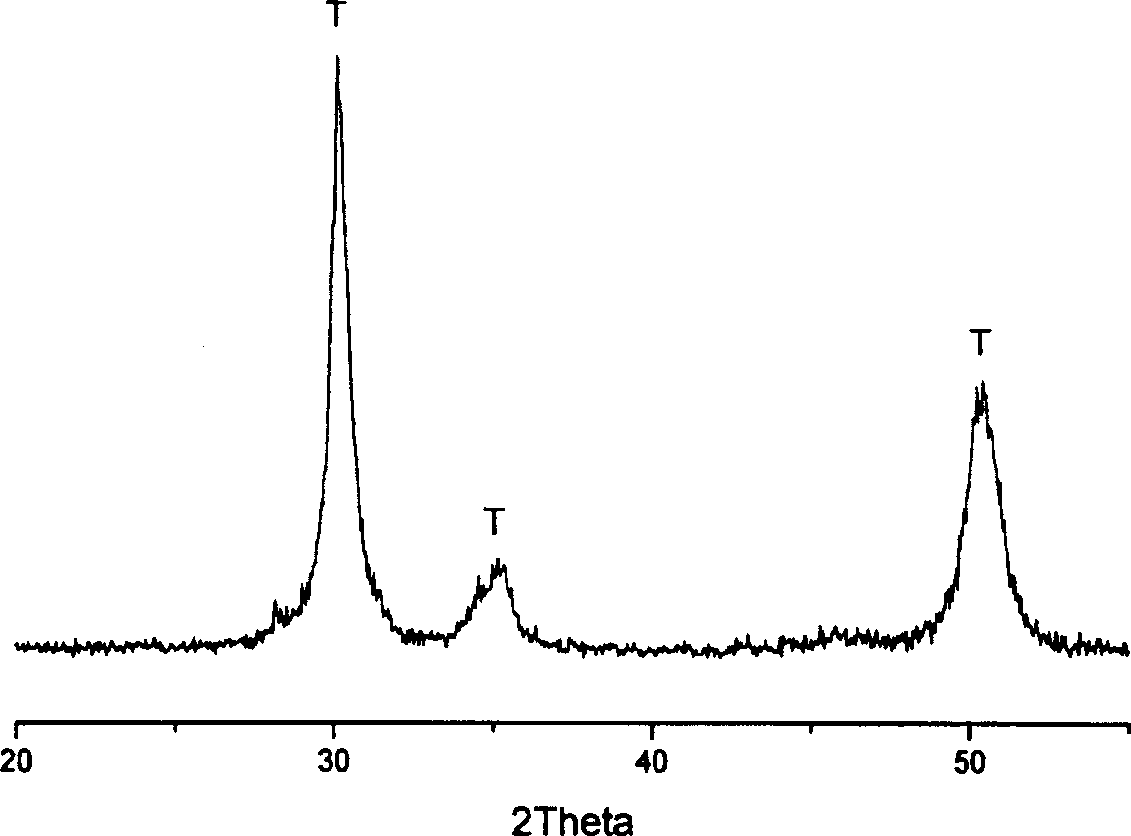

Image

Examples

preparation example Construction

[0016] The preparation method of the catalyst of the present invention comprises firstly preparing a mixture of silicon oxide and aluminum oxide, then mixing the mixture with zirconium hydroxide evenly, then impregnating with an aqueous solution of a sulfur compound, drying and forming the solid at 400-800°C Roasting.

[0017] The preparation method of the silicon oxide and aluminum oxide mixture is to uniformly mix the hydrated aluminum oxide and the silicon sol liquid, and then dry. The silicon dioxide content of the silica sol used is 10-50% by weight, preferably 35-45% by weight, and the two oxides are preferably mixed by grinding. The mixed solid material is preferably ion-exchanged with an ammonium salt solution to remove sodium ions. The temperature of the ion exchange is 80-90°C, the concentration of the ammonium salt solution used is preferably 10-20% by weight, and the ammonium salt is preferably ammonium chloride or ammonium nitrate. The mixture after grinding and...

example 1

[0029] Preparation of Zirconium Hydroxide

[0030] 400 grams of analytically pure zirconium oxychloride (ZrOCl 2 ·8H 2 (0, produced by North China Specialty Chemical Reagent Development Center) was dissolved in 1500 milliliters of deionized water, while stirring, slowly added 200 milliliters of strong ammonia water to a pH of 8, and the precipitate obtained was washed with deionized water and filtered until the filtrate was neutral. and could not detect Cl -1 , the solid was dried at 110 °C for 24 hours to produce amorphous Zr(OH) 4 powder.

example 2

[0032] Preparation of silica and alumina mixtures

[0033] Take 6 grams of silica sol (SiO 2 content is 41% by weight) was added to 65 grams of aluminum hydroxide (Germany, Condea company, brand SB) powder, ground evenly, and dried at 110° C. for 24 hours. Add 200 ml of 10% NH 4 Cl solution was refluxed for 3 hours under stirring at 80°C, washed with deionized water, filtered, and repeated three times, and dried at 110°C for 24 hours to prepare a mixture with silica and alumina contents of 5% by weight and 95% by weight respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com