Self-lubricating nano composite material and its preparation method

A nano-composite material and self-lubricating technology, applied in the field of nano-composite materials and their preparation, can solve the problems that have not been seen in literature and patent reports, and achieve the effects of improving friction and wear performance, good heat resistance, and improving tribological performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

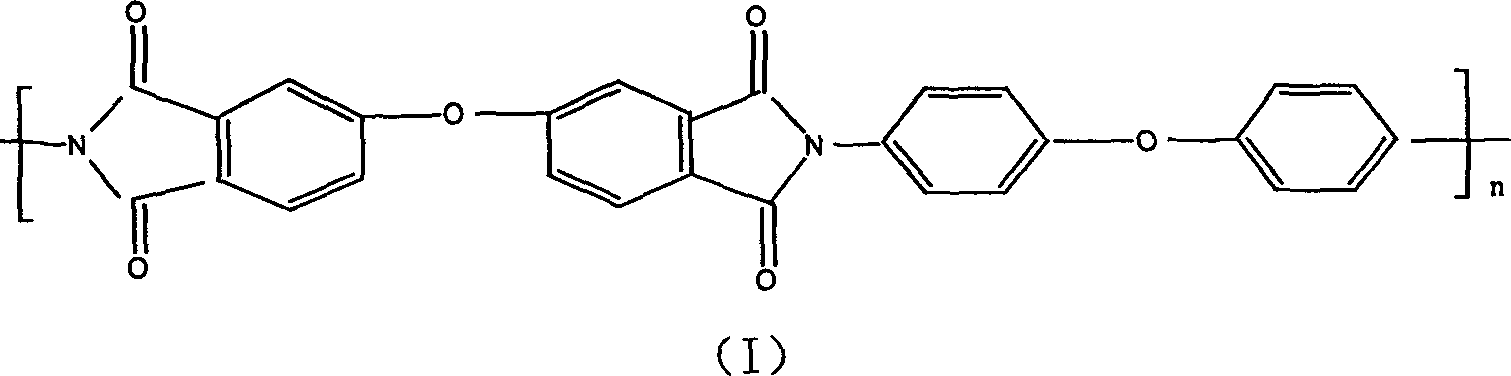

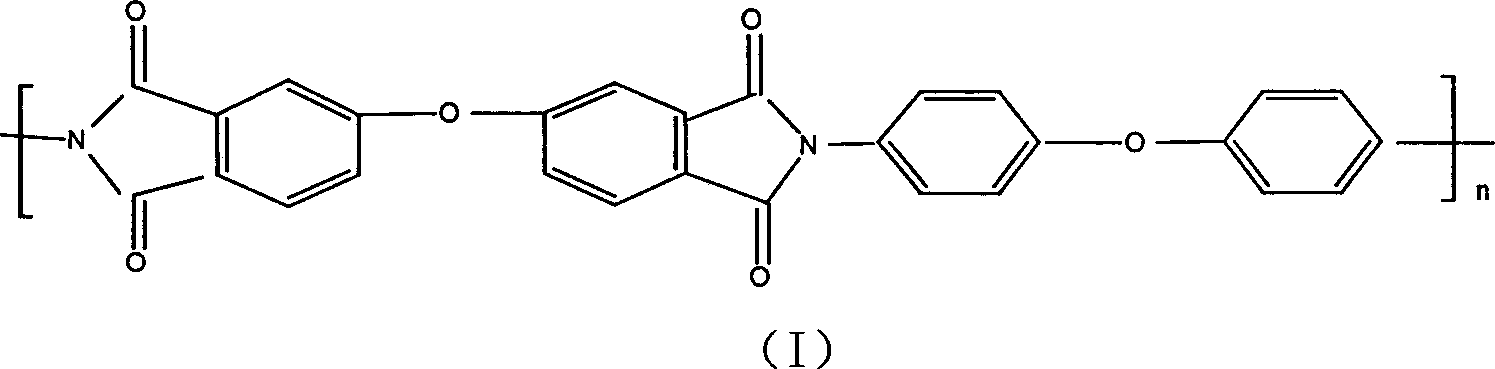

Image

Examples

Embodiment 1

[0027] Add 0.1 g of coupling agent and solvent N-methylpyrrolidone to 10 g of polyamic acid, 0.5 g of nano-nano silicon nitride, 0.2 g of nano-silicon dioxide, and 0.1 g of carbon nanotubes. In the polyamic acid system, blow nitrogen, dry, and mechanically stir for 7 hours, add 1.2 g of carbon fibers, and then fully stir for 3 hours. Precipitate the composite material quickly by heating method, treat it in a vacuum oven at 245°C for 3 hours, put the dried composite material into the mold, pressurize to 15Mpa, and then raise the temperature to 340°C at a rate of 6°C / min. Keep the temperature constant for 25 minutes, pressurize to 40Mpa, cool under the condition of maintaining pressure, and demould.

Embodiment 2

[0029] Add 0.2g of coupling agent and solvent N-methylpyrrolidone to 9g of polyamic acid, 0.6g of nano-nano-silicon nitride, 0.2g of nano-silicon dioxide, and 0.2g of carbon nanotubes. After ultrasonic treatment for 20 minutes to disperse evenly, add In the polyamic acid system, blow nitrogen, dry, and mechanically stir for 8.5 hours, add 2 g of carbon fibers, and then fully stir for 4 hours. Precipitate the composite material quickly with pyridine and acetic anhydride, treat it in a vacuum oven at 240°C for 4 hours, put the dried composite material into a mold, pressurize to 20Mpa, and then raise the temperature to 330°C at a rate of 6°C / min ℃, keep the temperature for 40 minutes, pressurize to 50Mpa, cool under the pressure keeping condition, and release the mold.

Embodiment 3

[0031] Add 0.15g of coupling agent and solvent N-methylpyrrolidone to 17.6g of polyamic acid, 1g of nano-silicon nitride, and 0.6g of carbon nanotubes. After ultrasonic treatment for 18 minutes to disperse evenly, add to the polyamic acid system and blow nitrogen , dried, and mechanically stirred for 10 hours, then added 2.7 g of carbon fibers, and then fully stirred for 4 hours. Precipitate the composite material quickly with pyridine and acetic anhydride, treat it in a vacuum oven at 250°C for 3 hours, put the dried composite material into a mold, pressurize to 20Mpa, and then raise the temperature to 350°C at a rate of 6°C / min. ℃, keep the temperature for 20 minutes, pressurize to 60Mpa, cool under the pressure keeping condition, and release the mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com