Process for growing P-type ZnO crystal film by real-time doping nitrogen

A p-type, crystal technology, applied in semiconductor/solid-state device manufacturing, ion implantation plating, coating, etc., can solve the problems of low nitrogen activity, unsatisfactory doping effect, toxicity, etc., and achieve good repeatability and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further illustrated below in conjunction with specific examples.

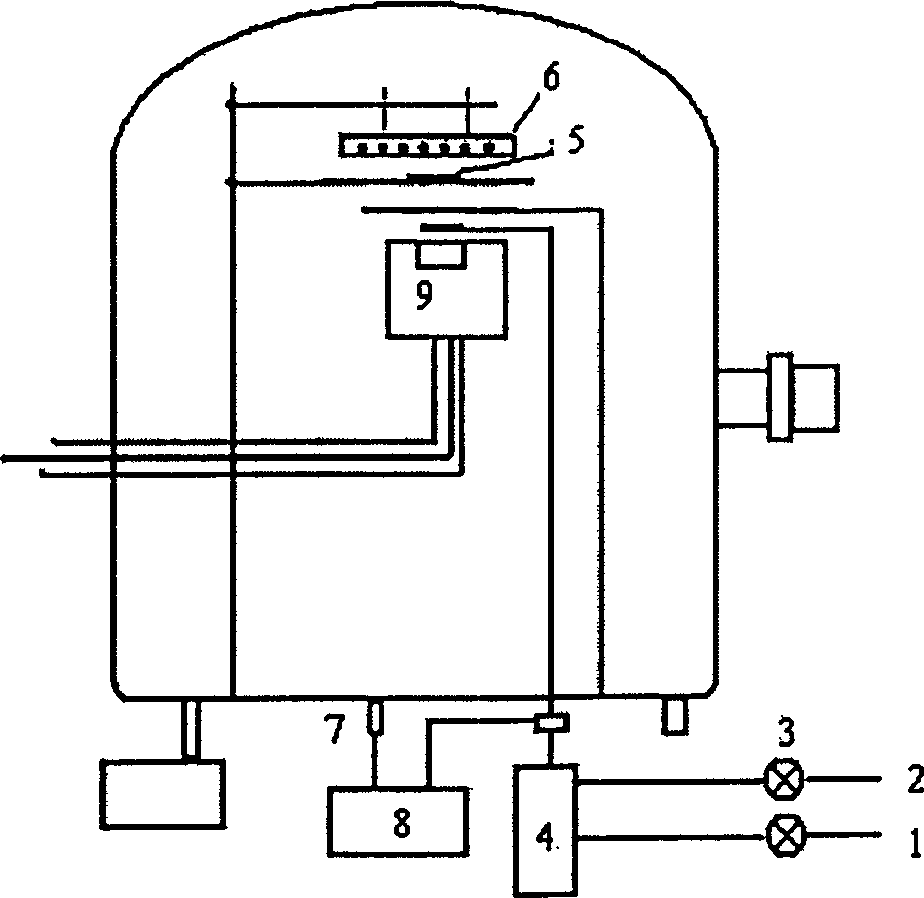

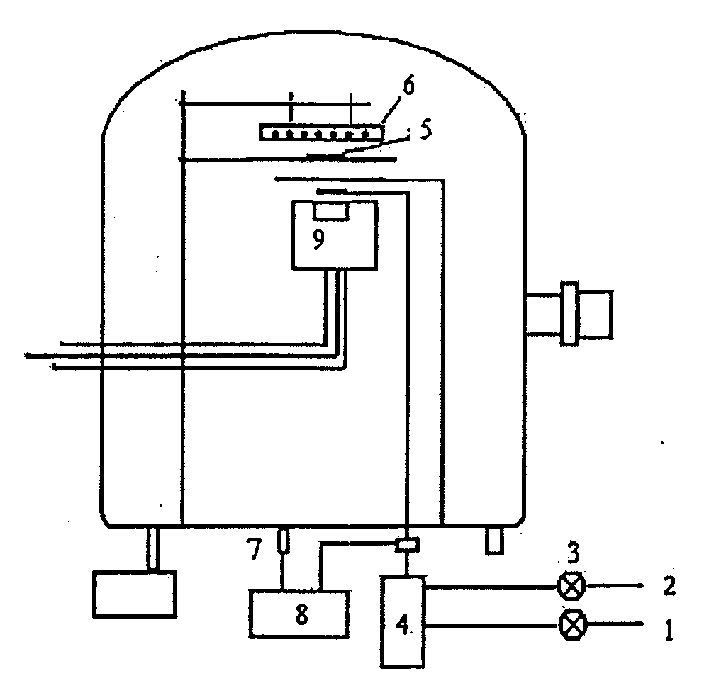

[0015] The substrate is first cleaned on the surface and placed on the sample holder 5 of the reaction chamber. The substrate is placed downward to effectively prevent the contamination of the substrate by particulate impurities. The vacuum of the reaction chamber is pumped to 10 -3 Pa; Use a heater to heat the substrate, and the substrate temperature is controlled at 500°C; the sputtering gas is high-purity NH 3 (99.99% or more) and high purity O 2 (Above 99.99%), the two gases enter the buffer chamber 4 through the air inlet pipes 1 and 2, and are introduced into the vacuum chamber after the buffer chamber is fully mixed. The pressure in the vacuum chamber is controlled by the automatic pressure controller 8, and the pressure is about 5Pa. NH 3 With O 2 The partial pressure ratio can be adjusted arbitrarily through the flow meter 3 according to the doping requirements. In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com