Building material converted from fly ash and preparation method thereof

A technology of conversion and treatment of building materials, applied in the direction of sustainable waste treatment, clay products, solid waste management, etc., can solve the problems that the brick-making process fails to achieve satisfactory results, cannot be well promoted and applied, and achieves Save precious land, reduce secondary pollution, and solve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-3

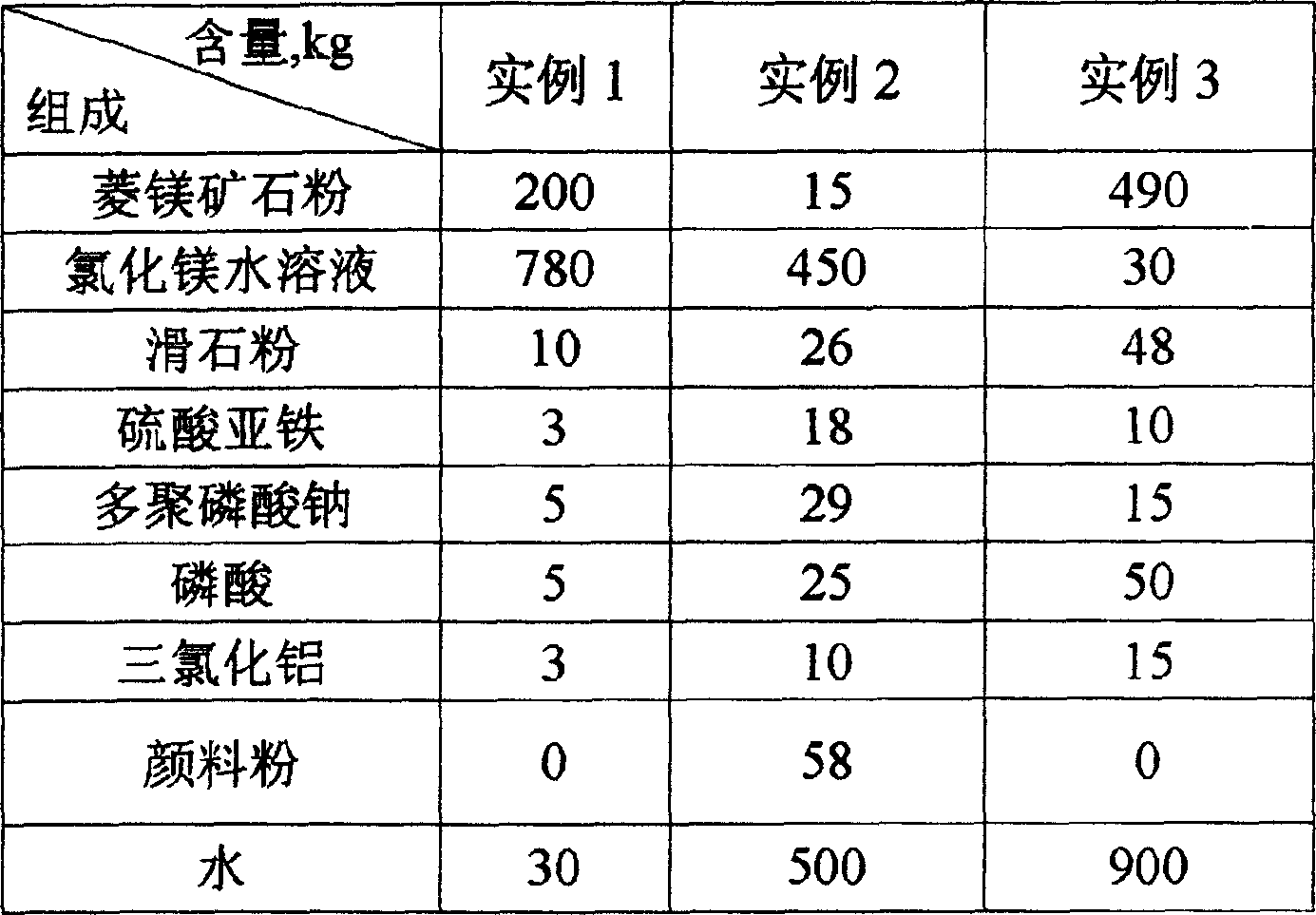

[0023] Example 1-3 is to prepare catalyst coagulant, and its composition and content are shown in Table 1.

[0024] Preparation method: Stir the raw materials well and evenly.

example 4

[0026] This example is to prepare a solid brick of 150×150×150mm. Raw material proportioning used: 100 kilograms of fine coal mine of Taizhou Power Plant (its chemical composition is shown in Table 2), 40 kilograms of catalytic coagulant of example 1, 60 kilograms of sand and 40 kilograms of water.

[0027] Preparation method: After mixing the raw materials in a mixer, pour them into a mold of 150×150×150mm, vibrate and extrude them, send the blanks out of the mold to the indoor curing room, heat and cure them with steam at 165°C for 13 hours, and then put them in the natural environment. Conservation yard, natural conservation for 28 days, to get the required products.

[0028] The product was tested by the material laboratory of Taizhou Highway Management Office: (1) load 520KN, single strength 23.1MPa; (2) load 530KN, single strength 23.6MPa; (3) load 560KN, single strength 24.9MPa, average strength 23.8 MPa.

example 5

[0030] This example is to prepare a sample of 240×115×53mm.

[0031] Raw material ratio used: 150 kilograms, 60 kilograms, 90 kilograms, 35 kilograms of water of the catalytic coagulant of Shanghai Minhang power plant fly ash (its chemical composition is shown in Table 2), example 2.

[0032] Preparation method: Mix the above raw materials in a mixer and inject them into a mold of 240×115×53mm, vibrate and extrude them, send the blanks out of the mold to the indoor curing room, heat and cure them with steam at 170°C for 10 hours, and then send them to The storage yard is naturally maintained for 28 days to obtain the required samples.

[0033] The samples were tested by the Construction Engineering Quality Inspection Station of Shanghai University.

[0034] Testing method: according to GB / 12542-92 compressive strength testing equipment, pressure testing machine, model NyL-600CT08, anti-analysis strength testing equipment, hydraulic universal testing machine, model WE-50GJ09. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com