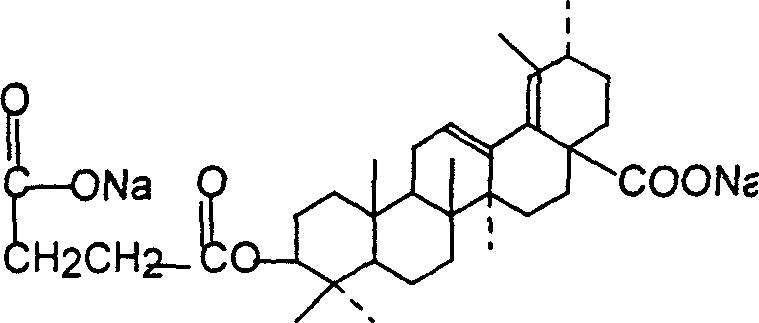

Preparation of 3beta-succinyl-18-disodium salt dehydro ursolic acid

A technology of ursolic acid disodium salt and succinyl group, which is applied in the field of preparation of 3β-succinyl-18-dehydroursolic acid disodium salt, can solve the problems such as undescribed preparation methods, and achieve low production cost and high product quality. The effect of convenient separation and purification and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

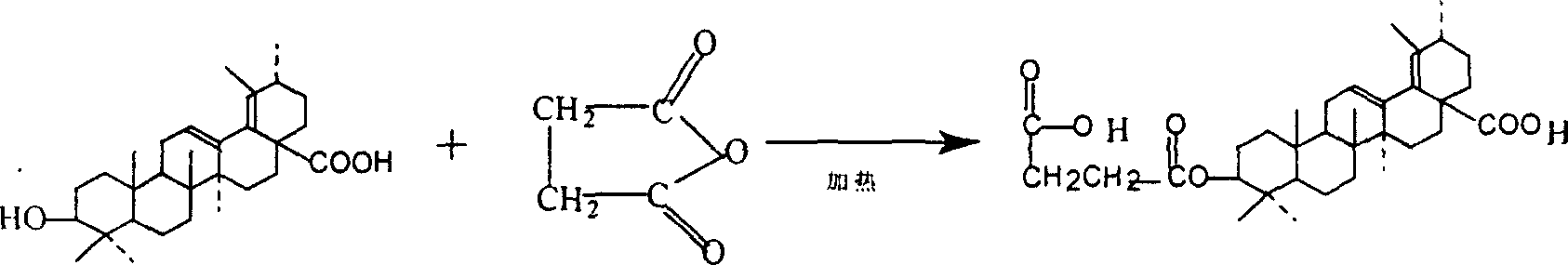

Method used

Image

Examples

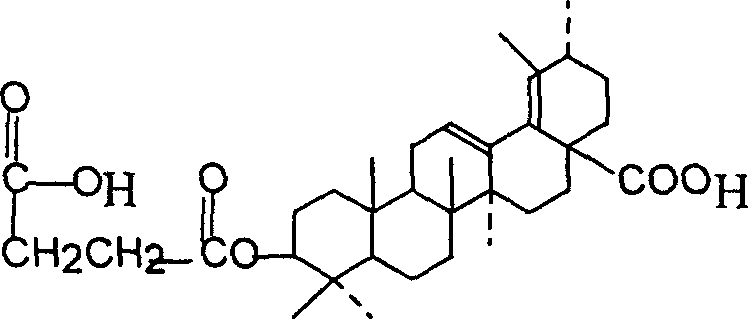

Embodiment 1

[0022] Get the root / stem of 100 kilograms of Ilex pubescens and cut into small pieces, put it in the extraction pot, and use 400 liters of ethanol to reflux each time, extract 3 times altogether, combine the filtrate, concentrate to 250 liters, add 10 Liter of concentrated sulfuric acid was hydrolyzed under reflux for 3 hours, filtered after cooling, and the solid was washed with water until neutral and nearly white to obtain a crude product. The crude product was recrystallized with ethanol and activated carbon to obtain 206 grams of white 18-dehydroursolic acid with a content of 97% and a melting point of 287-289°C. Put 18-dehydroursolic acid in a three-necked flask and add 1000 ml of pyridine , heat to dissolve at 95°C, add 120g of succinic anhydride, add 10ml of concentrated sulfuric acid, react for 6 hours, add dilute hydrochloric acid, precipitate precipitate, filter, wash with water until almost no pyridine smell, dissolve the solid in ethanol, stir and add 50% NaoH sol...

Embodiment 2

[0025] Extract 18-dehydroursolic acid with the method in Example 1, weigh 20 g (content: 98.5%) of 18-dehydroursolic acid, put it in a three-neck flask, add 100 ml of pyridine, heat to dissolve at 90 ° C, add 24 g of succinic anhydride , add 1ml of concentrated sulfuric acid, continue to heat and stir to react, after 8 hours the reaction is complete, add dilute hydrochloric acid to precipitate, filter, wash with water, dissolve the solid in ethanol, add 30% NaoH solution under stirring, wait until the reaction is complete, place at low temperature After the crystallization is complete, filter and recrystallize with 75% ethanol. Suction filtration and drying yielded 21.5 g of 3β-succinyl-18-dehydroursolic acid disodium salt with a content of 98% and a yield of 81.22%.

Embodiment 3

[0026] Example 3. Weigh 20g (98.5%) of 18-dehydroursolic acid in a three-necked flask, add 100ml of pyridine, heat and dissolve in an oil bath, add 36g of succinic anhydride, and continue heating to 115°C for reaction. After reacting for 10 hours, add dilute acid, filter and wash with water to neutrality, dissolve the solid in ethyl acetate, stir and add 10% NaoH solution, after the reaction is complete, crystallize at a low temperature, filter, recrystallize with water, and place in 4 Crystallize overnight below ℃. The solid was suction filtered and dried to obtain 18.5 g of 3β-succinyl-18-dehydroursolic acid disodium salt, the content of which was greater than 98.5%, and the yield was 70.25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com