Method of synthesizing strontium titanate solid nuclear waste material

A technology of strontium titanate and nuclear waste, applied in the field of effective treatment of radioactive waste rich in strontium nuclides, to achieve the effects of low leaching rate, high density and high Vickers hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In this test, chromium trioxide, titanium powder, strontium oxide, and titanium dioxide are used as raw materials, and chromium trioxide is used as an oxidant. The reaction equation is as follows

[0018] (1)

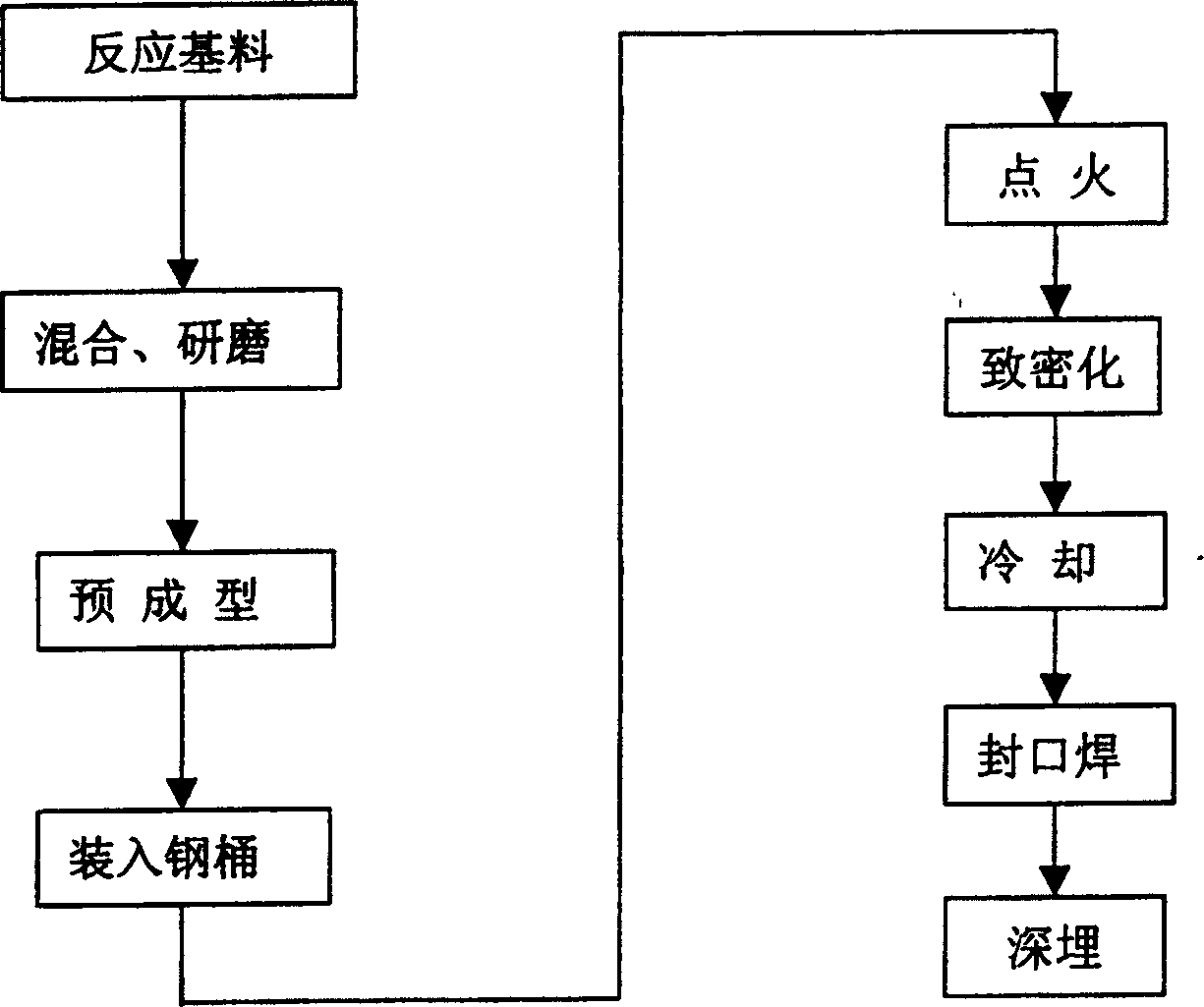

[0019] First, put the raw materials required for the reaction into a stainless steel ball mill and grind them to below 70 μm, and press CrO after sieving 3 , Ti, SrO and TiO 2 The molar ratio is 2:3:4:1 mixed powder. According to their molecular weight and content, the mass percentage can be calculated as 23.86:17.14:49.46:9.54; mix the powder according to the mass percentage calculated above, put it into a ball mill jar, and ball mill for 30 minutes, then take out the powder and pour it into a dark seal bottle, store in a cool dry place.

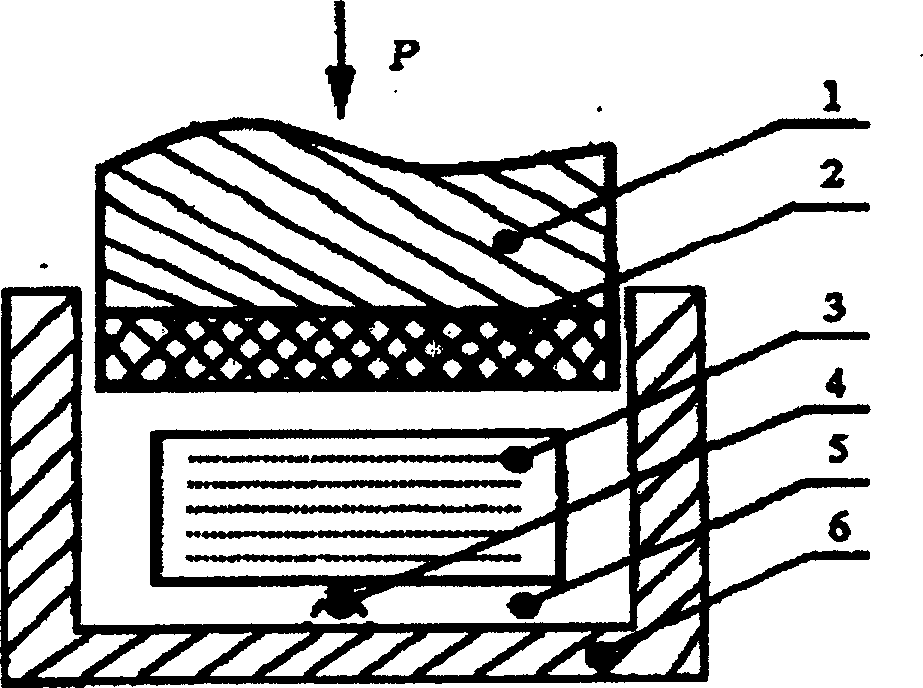

[0020] Take 30g of the mixed material and put it into a mold with a diameter of Φ25mm×a height of 180mm, pressurize 200Mpa on a YA-10 hydraulic press to make a compact, and then take out the compact. Extend the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com