Modified epoxy resin coated slow-release fertilizer with spray coating urea as bottom coat

An epoxy resin and controlled-release fertilizer technology, which is applied in the form of fertilizers, fertilizer mixtures, fertilization devices, etc., can solve the problems of poor nutrient controlled release, difficult solvent recovery, poor toughness, etc., to improve fertilizer utilization, transportation and Easy to store and improve the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

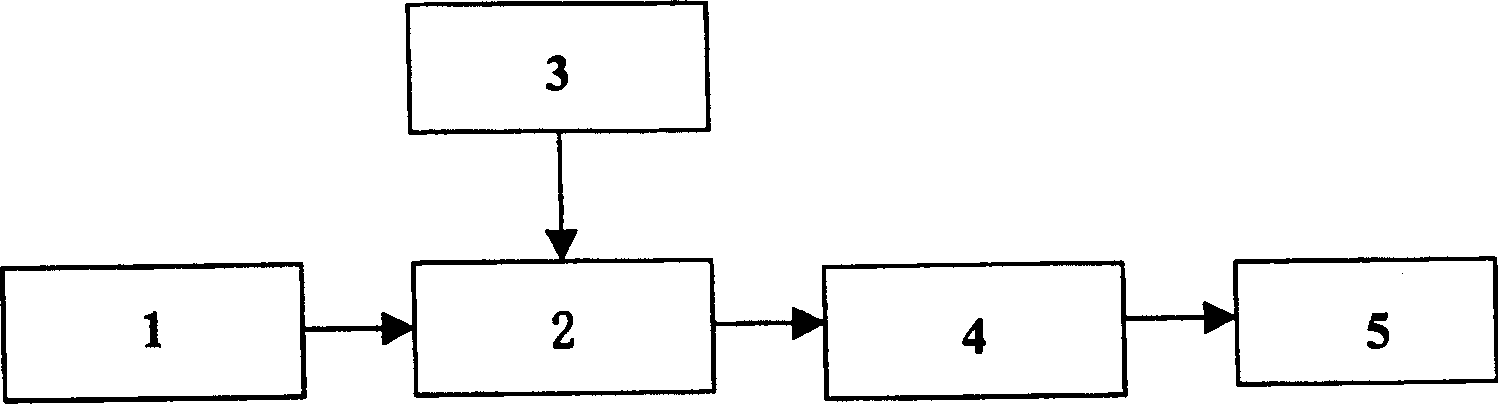

[0013] Add 5kg of urea into the fast melter (1), control the temperature at 120-130°C, after it is completely melted into urea liquid (2), spray it evenly on the preheated to 50°C with a two-fluid pressure nozzle 90kg of compound fertilizer granules (about 2-3mm in diameter) (3); then, gradually heat the fertilizer to about 90°C, and cure about 1.5kg of modified epoxy resin (E44 / PUR=95 / 5) About 0.15kg of agent T-593, about 0.05kg of diluent benzyl glycidyl ether 921, and 0.05kg of bentonite are mixed evenly, and then gradually added to the top of the fertilizer granules in the drum (4). The rotation speed of the drum is about 40 rpm. After about 8 minutes, the epoxy resin component can solidify and form a film on the surface of the fertilizer particles. This process is repeated 3 times. Finally, the fertilizer is cooled to room temperature by the cooler and can be packaged. storage (5). The obtained controlled-release fertilizer product has a controlled release of nutrients f...

Embodiment 2

[0015] Put 5kg of urea into the fast melter and convert it into urea liquid (2), spray evenly on 88kg of compound fertilizer granules that have been preheated to 50°C in the fluidized bed (3), and then transfer it into the drum , Add about 2.0kg of modified epoxy resin, about 0.3kg of curing agent T31, about 0.1kg of diluent AEG, and 0.02kg of bentonite according to step 1. The temperature required for curing is 86°C±2°C for about 5 minutes, and the adding process is repeated 3 times (4). The obtained product is packaged and stored after cooling (5). The obtained controlled-release fertilizer product can control the release time of nutrients for about 180 days under the condition of 25°C.

Embodiment 3

[0017] Put 5kg of urea into the fast melter and convert it into urea liquid (1), evenly spray it on 85kg of compound fertilizer particles preheated to 50°C in the fluidized bed (2), add modified epoxy resin (E44 / PUR=95 / 5) about 1.8kg, curing agent diethylenetriamine about 0.2kg, diluent tributyl phosphate about 0.02kg, diatomaceous earth 0.02kg, after mixing evenly, gradually add to the surface of the fertilizer particles in the drum Step (3) and (4), after about 7 minutes, it can solidify and form a film on the surface of the fertilizer. This process was repeated 5 times. Finally cooled to room temperature. It can be packaged and stored (5). The obtained controlled-release fertilizer product can control the release of nutrients for about 270 days at 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com