Method for producing multi-layer nano composite proton exchange membrane with self-humidifying function

A proton exchange membrane and nanocomposite technology, which is applied in the field of preparation of multilayer nanocomposite proton exchange membranes, can solve the problems of increasing contact interface, self-discharging battery, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

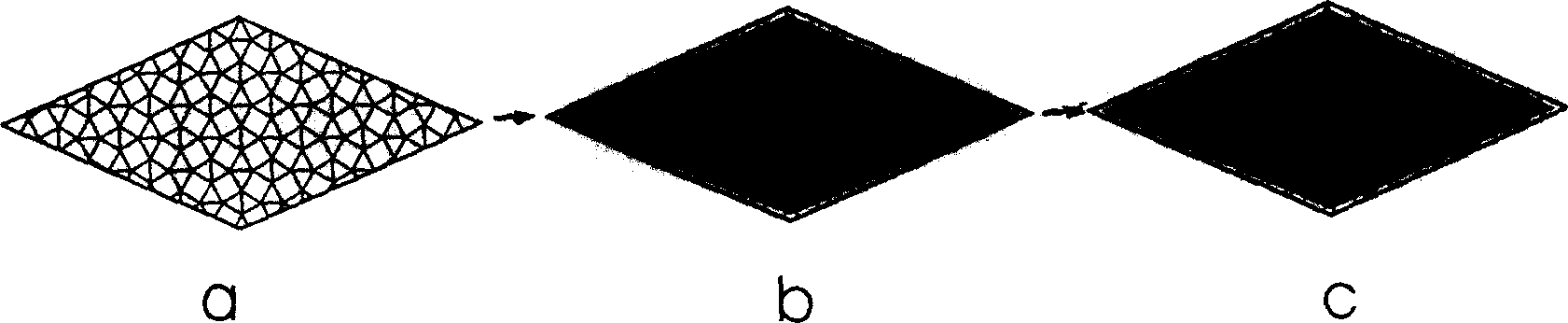

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 has the preparation of the multilayer nanocomposite proton exchange membrane of self-humidification and water retention capacity, carries out according to the following steps;

[0033] 1. Get a porous PTFE membrane with a thickness of 10 microns, a pore size of 0.05 to 2 microns, and a porosity of 80% and fix it on a polycarbonate film with a thickness of 40 microns. 2 o 2 Wash the PTFE membrane with aqueous solution and absolute ethanol, and then dry it in a drying oven at 60°C for 20 minutes;

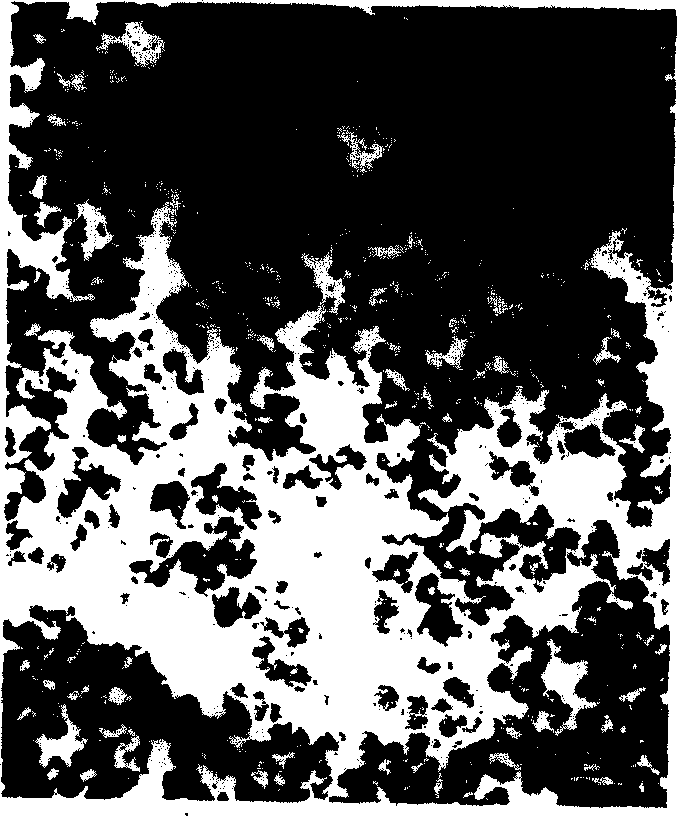

[0034] 2. Fully mix tetraethyl orthosilicate with a molar ratio of 1:5:0.1, absolute ethanol and 0.4M HCl mixed solution, and stir at a high speed at 70°C for 6 to 24 hours to obtain 6 nanometer SiO 2 Nanoparticles; by 5wt% Nafion solution (EW1100, purchased from Du pont company) 120g, surfactant alkylphenol polyoxyethylene 10 ether (OP-10) 1.3g, SiO 2 Nanoparticle 0.5g prepares mixed solution, the PTFE porous film that will clean is dipped in this mixed solution...

Embodiment 2

[0038] Embodiment 2 The preparation of the multilayer nanocomposite proton exchange membrane with self-humidification and water retention capacity is carried out according to the following steps;

[0039] 1. Get a porous PTFE membrane with a thickness of 20 microns, a pore size of 0.05 to 3 microns, and a porosity of 82% and fix it on a polycarbonate film with a thickness of 40 microns. 2 o 2 Wash the PTFE membrane with aqueous solution and absolute ethanol, and then dry it in a drying oven at 60°C for 20 minutes;

[0040] 2. Mix 200mL tetrabutyl titanate and 60mL acetic acid and put it in the filter funnel, drop the mixed solution into 800mL deionized water under high-speed stirring at a speed of 10mL / min, continue stirring for 1 hour, and then add 15mL concentrated nitric acid Heated to 60°C and continued to stir for 2 hours to obtain 7 nm TiO 2 Nanoparticles; by 10wt% sulfonated polystyrene-polyethylene / butylene-polystyrene resin isopropanol solution 80g, OP-10 surfactant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com