City sludge biofertilizer

A technology of municipal sludge and bio-fertilizer, applied in the direction of sewage/sludge fertilizer, sludge treatment, biological sludge treatment, etc., can solve the problems affecting the quality of soil environment and crop quality, the decline of agricultural product quality and yield, and the pollution of agricultural chemicals To achieve the effect of enhancing permeability and water and fertilizer retention capacity, strong aerobic fermentation and decomposition capacity, and preventing soil salinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Enzyme bacteria 21.6 kg Shale powder 43.2 kg

[0018] Rice Bran 260kg Brown Sugar 43.2kg

[0019] 432 kg of sludge, 250 kg of nitrogen, phosphorus, and potassium fertilizers

Embodiment 2

[0020] Embodiment two (beet fertilization ratio)

[0021] Enzyme bacteria 21.6 kg Shale powder 43.2 kg

[0022] Rice Bran 260kg Brown Sugar 43.2kg

[0023] Sludge 432 kg Nitrogen fertilizer 100 kg

[0024] Phosphate fertilizer 70 kg Potassium fertilizer 80 kg

Embodiment 3

[0025] Embodiment three (soybean fertilization ratio)

[0026] Enzyme bacteria 21.6 kg Shale powder 43.2 kg

[0027] Rice Bran 260kg Brown Sugar 43.2kg

[0028] Sludge 432 kg Nitrogen fertilizer 60 kg

[0029] Phosphate fertilizer 120 kg Potassium fertilizer 70 kg

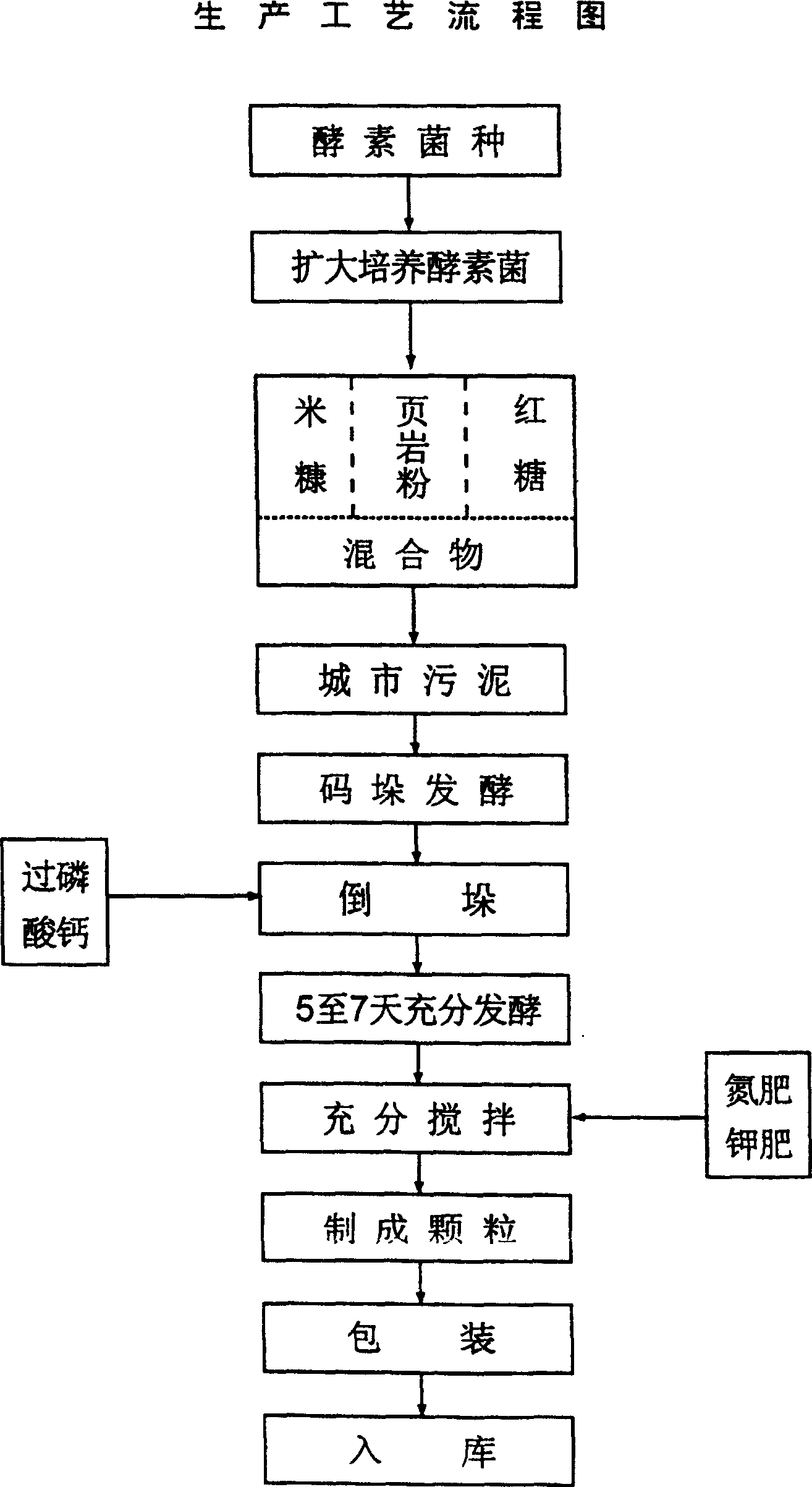

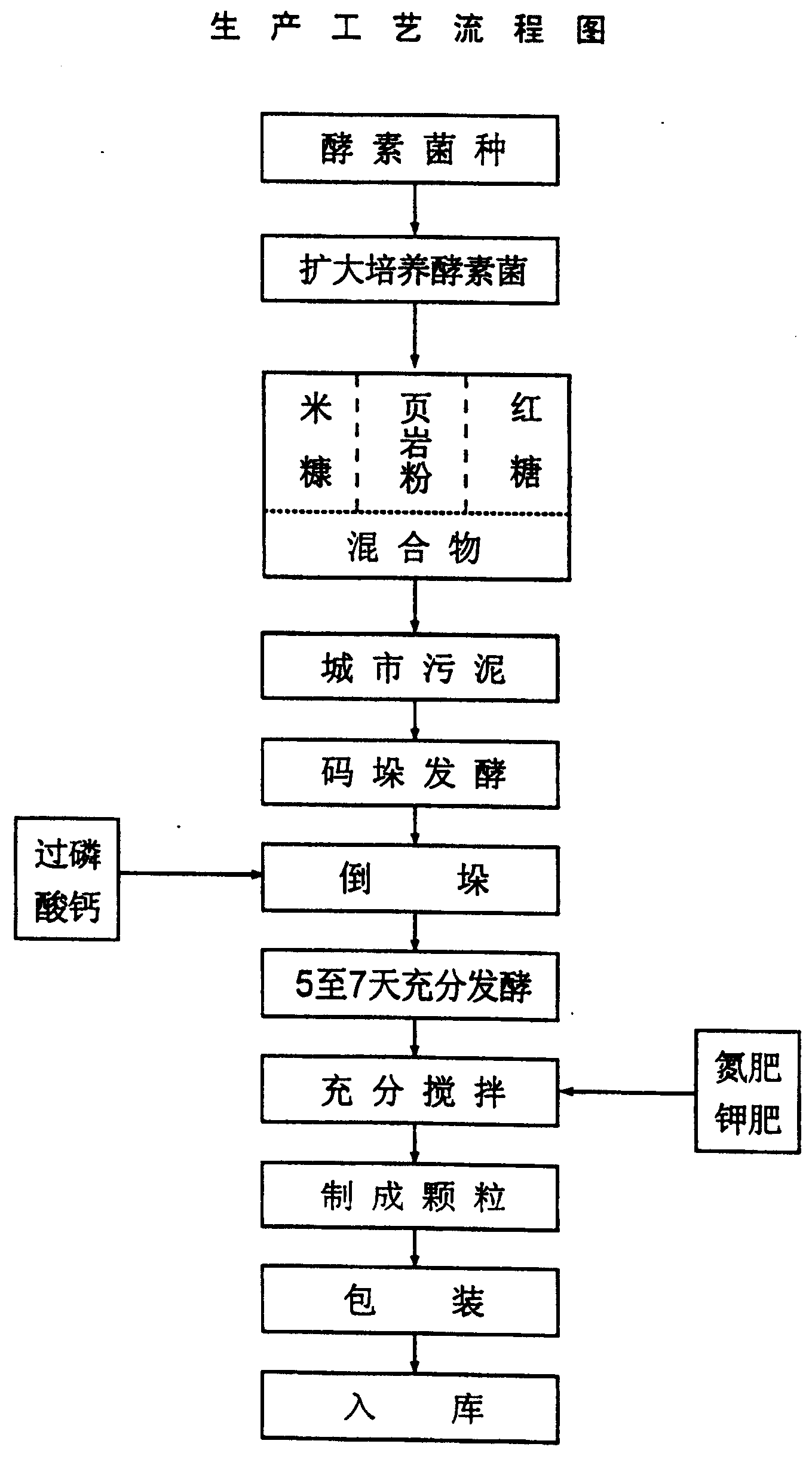

[0030] Municipal sludge biological fertilizer of the present invention, its preparation process is as follows:

[0031] 1. Raw material selection: rice bran should be newly produced and well-preserved, without caking or mold; the cation exchange capacity (CEC) of shale powder must be ≥ 80, and the heavy metal content should meet the national agricultural fertilizer content standard (see attached Table II)

[0032] 2. Technological conditions: In the dark and aerobic state, the on-site temperature cannot be lower than 15°C, and the humidity is 30-45%; the fermentation temperature is 45°C-70°C, and the temperature is measured 6 times a day; the fermentation period is 5-7 days ; Invert stack once a day.

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com