Preparing method of nerve tissue engineering tube type bracket and special mould for the same

A nerve tissue, tubular technology, applied in the field of biomedical materials and tissue engineering, can solve the problems of unable to maintain the structure, difficult to preset cells, unsuitable for small-bore catheters, etc., to achieve the effect of promoting nerve regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method provided by the present invention is as follows:

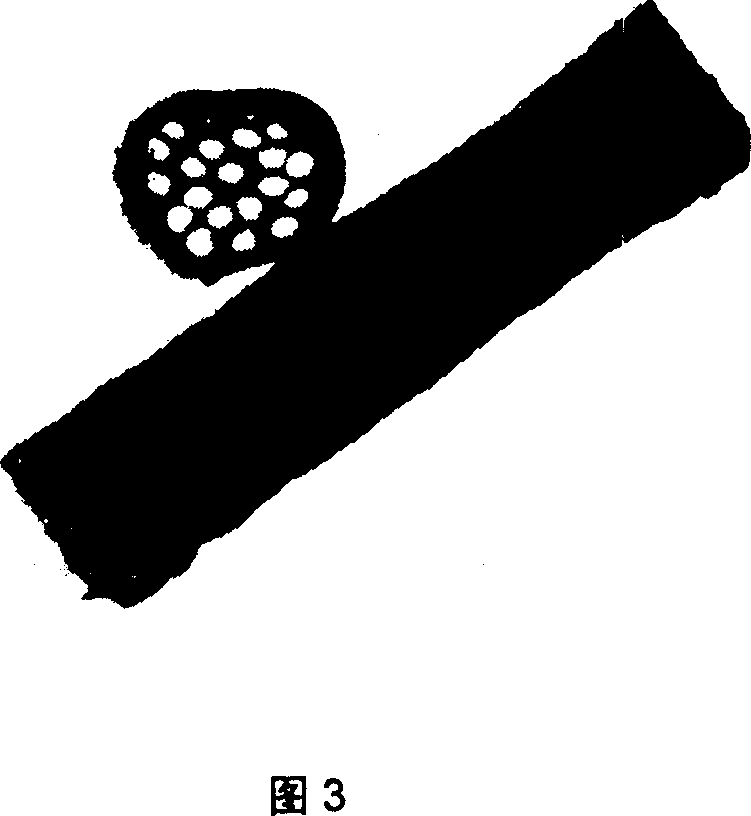

[0023] (1) Dip the PTFE-coated stainless steel rod core mold (1~5mm in diameter) into 2~4% (w / v) chitosan solution (prepared with 0.2mol / L acetic acid solution), pull it out, Freeze, then immerse, pull out, and freeze at least 3 times, then freeze at -20°C to -96°C for 12 to 48 hours, and then place it in a freeze dryer for freeze drying. Soak the dried chitosan round tube with a core mold in a 2% (w / v) sodium hydroxide solution for 10-30 minutes, take it out, rinse with deionized water to neutrality, and then immerse it in pH=7.2-7.4 in phosphate buffer for 10-30 minutes. Use filter paper to absorb moisture on the surface of the chitosan tube and dry it naturally. Take out the stainless steel rod core mold, and finally obtain a semi-permeable chitosan round tube with a wall thickness of 0.4-1.0 mm.

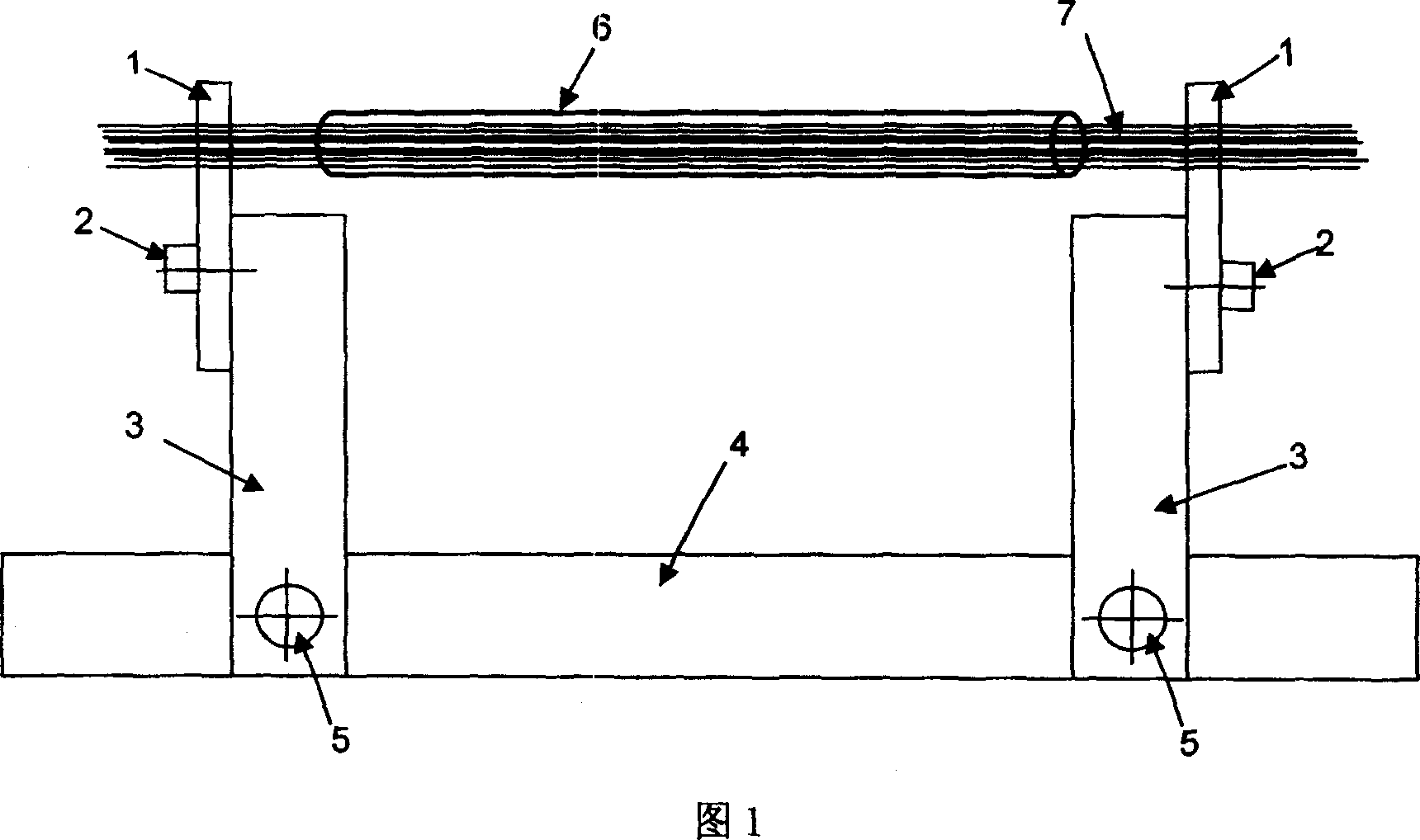

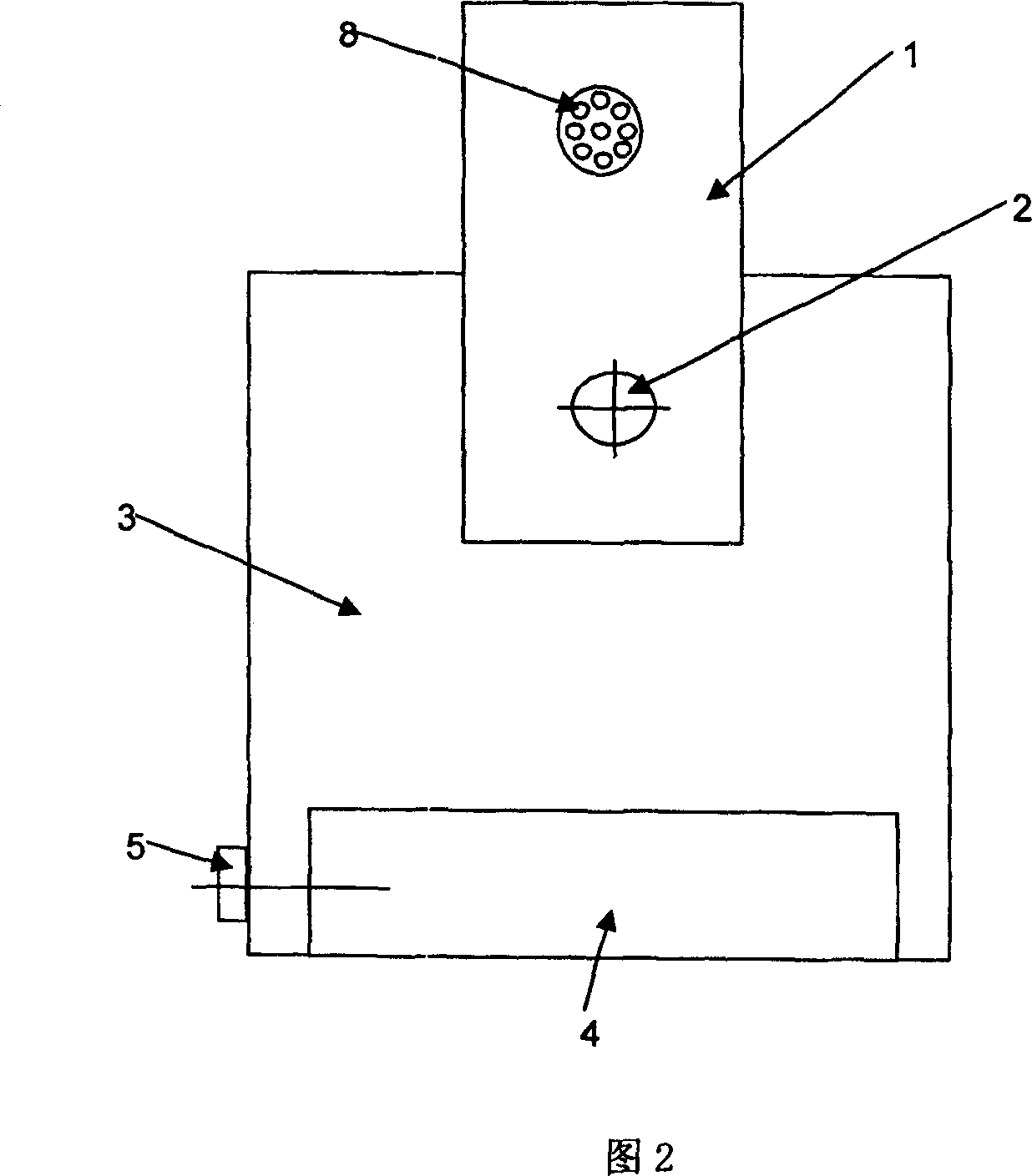

[0024] (2) The mold shown in Figure 1 can be used to prepare the multi-channel matrix. The mold inclu...

Embodiment 1

[0027] (1) Dip the stainless steel rod core mold with a diameter of 1mm PTFE-coated into 2% (w / v) chitosan solution (prepared with 0.2mol / L acetic acid solution), pull out, freeze, then immerse and pull out Take out and freeze, repeat 3 times, then freeze at -20°C for 12 hours, then place it in a freeze dryer for freeze drying. Soak the dried chitosan round tube with a core mold in a 2% (w / v) sodium hydroxide solution for 10 minutes, take it out, rinse with deionized water to neutral, and then soak in pH= 7.2 ~ 7.4 phosphate buffer for 10 minutes. Use filter paper to absorb the moisture on the surface of the chitosan tube and dry it naturally. Take out the stainless steel rod core mold, and finally obtain a semi-permeable chitosan round tube with a wall thickness of 0.4 mm.

[0028] (2) As shown in the figure, the chitosan tube 6 with a length of 1cm is placed between the two steel needle fixing plates 1 on the special mold (Figure 1), and 7 stainless steel needles with a diameter...

Embodiment 2

[0030] (1) Dip the stainless steel rod core mold with a diameter of 5mm PTFE coated into 4% (w / v) chitosan solution (prepared with 0.2mol / L acetic acid solution), pull out, freeze, then immerse and pull out Take out and freeze, repeat 5 times, then freeze at -196°C for 48 hours, then place it in a freeze dryer for freeze drying. Soak the dried chitosan tube with a core mold in a 2% (w / v) sodium hydroxide solution for 30 minutes, take it out, rinse with deionized water to neutral, and then immerse it in pH= 7.2 ~ 7.4 phosphate buffer for 30 minutes. Use filter paper to absorb the moisture on the surface of the chitosan tube and dry it naturally. Take out the stainless steel rod core mold, and finally obtain a semi-permeable chitosan round tube with a wall thickness of 1.0 mm.

[0031] (2) As shown in the figure, the chitosan tube 6 with a length of 10cm is placed between the two steel needle fixing plates 1 on the special mold (Figure 1), and 50 stainless steel needles 7 with a dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com