Doping and surface coating lithium nickel cobalt dioxide and its preparing method

A technology of surface coating and lithium nickel cobalt oxide, which is applied in the direction of electrode manufacturing, electrical components, battery electrodes, etc., can solve the problems of lack of market competitive advantage, raw material cost cannot be reduced, and high raw material cost, and is suitable for industrial scale production , low production cost, high specific capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

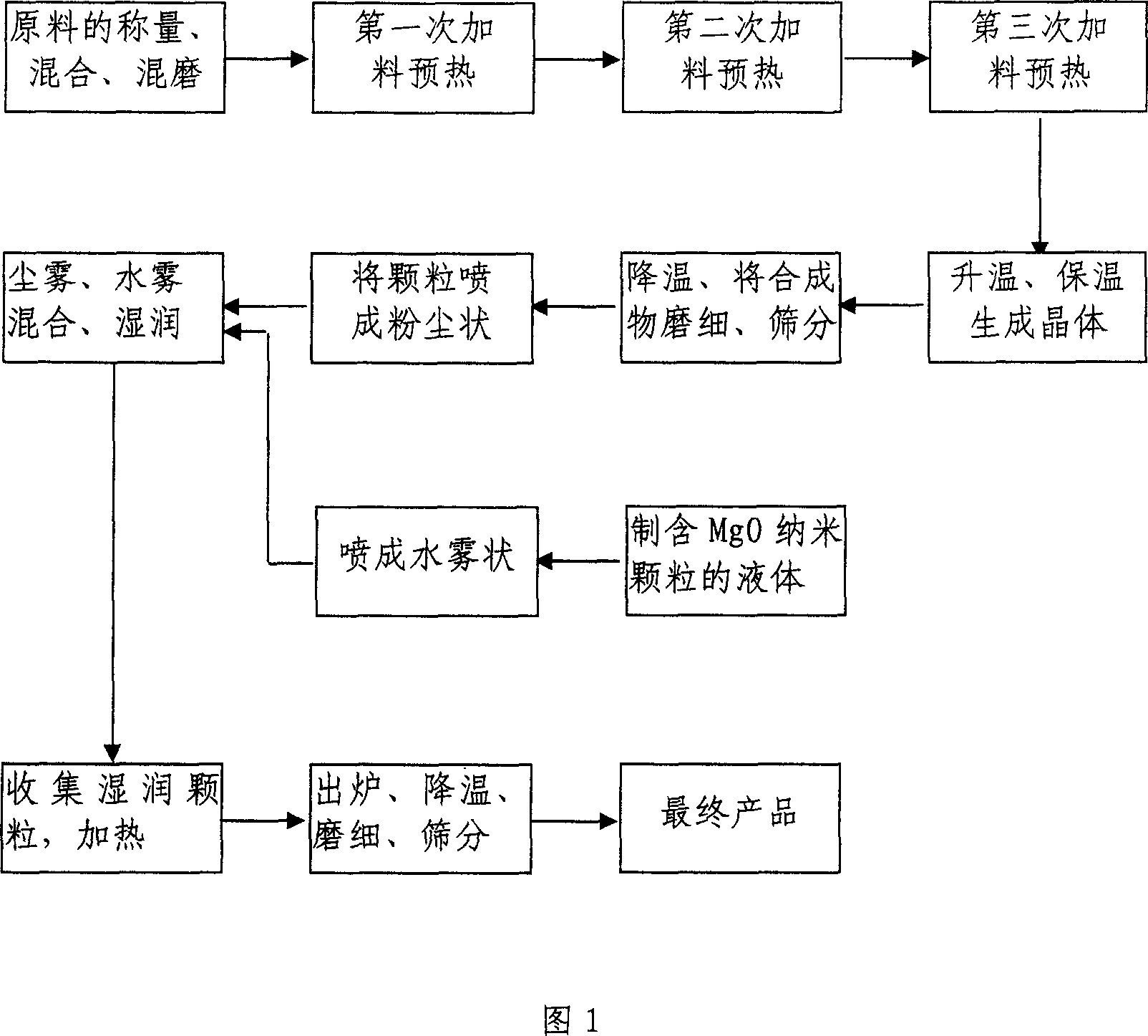

Method used

Image

Examples

Embodiment 1

[0036] (1) Take by weighing the higher purity reactant raw material lithium carbonate, nickel carbonate, cobalt carbonate, magnesium carbonate, mix grind;

[0037] (2) Using the heating device of the electric heating tunnel heating furnace, put the mixed and ground mixture raw materials into a flat-bottomed ceramic bowl, and put it into a quarter of the capacity of the bowl. The ceramic flat-bottomed bowl with good raw materials is sent into the tunnel heating furnace for heating through porcelain rollers, and the air atmosphere is heated at a heating rate of 20°C / min. When the temperature reaches 300°C, it is kept for 0.5 hours;

[0038] (3) Take the ceramic flat-bottomed bowl of step (2) out of the furnace, wait for it to cool, and then fill it with a mixture of a quarter of its capacity, vibrate the surface, reset the heating furnace to heat, air atmosphere, according to the heating rate Heating at 20°C / min, when the temperature reaches 300°C, hold for 0.5 hours;

[0039]...

Embodiment 2

[0048] The difference from Example 1 is that manganese carbonate is used instead of magnesium carbonate, and the consumption is also that the mole fraction of manganese is 0.1.

Embodiment 3

[0050] The difference from Example 1 is that nickel oxide, cobalt oxide, and magnesium oxide are used instead of nickel carbonate, cobalt carbonate, and magnesium carbonate in Example 1, and the mole fraction ratio of each metal element remains unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com