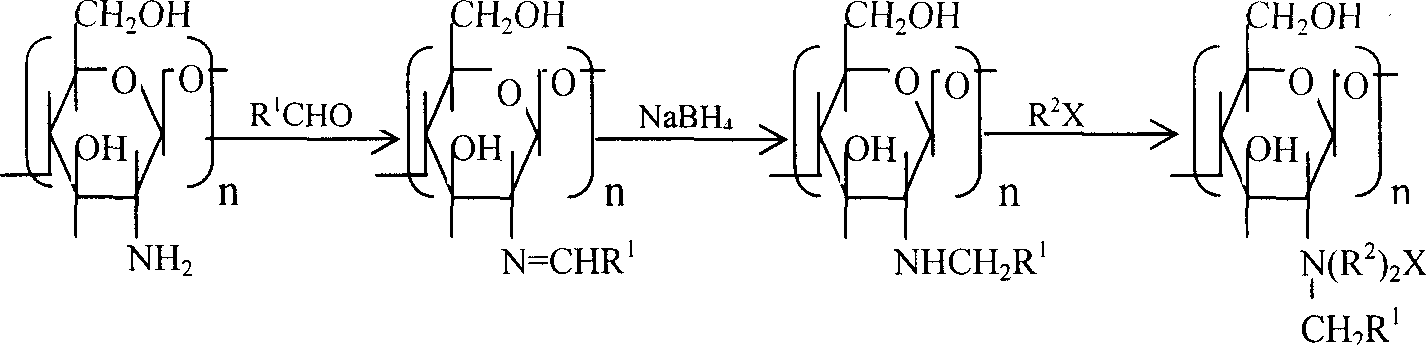

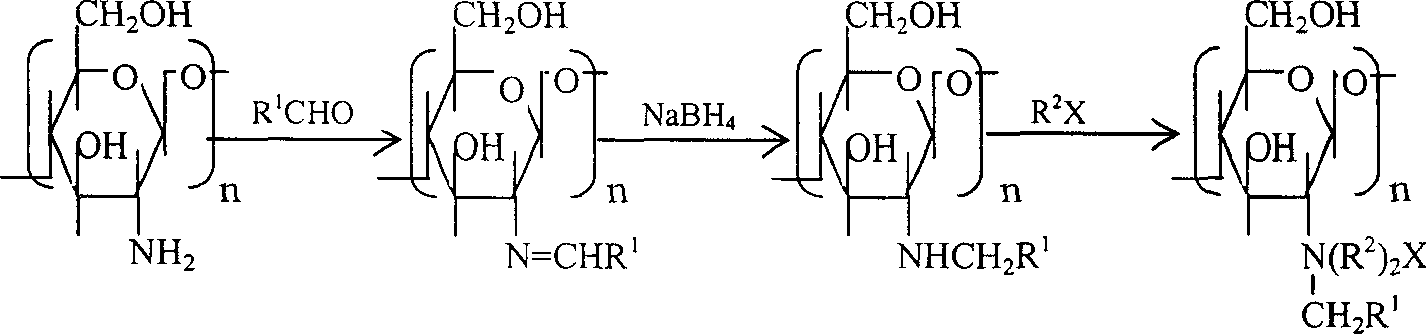

Process for preparing chitosan quaternary ammonium salt

A technology of chitosan quaternary ammonium salt and quaternary ammonium salt, which is applied in the field of preparation of chitosan quaternary ammonium salt, can solve the problems of difficult product separation and purification, low substitution degree of chitosan quaternary ammonium salt, etc. The effect of high, low cost, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of N, N-dimethyl-N-alkyl or N-aryl chitosan iodide quaternary ammonium salt

[0025] Chitosan of various molecular weights through hydrogen peroxide degradation (preparation method sees: Tsuguhei k, Tatsusaki Y., JP 09031104, 1997, 02-04; Luo Ping, He Bobing etc., chemical research and application, 12 (5), 2000 Lu Fengqi, Cao Zongshun, etc., Chinese Journal of Biochemical Medicine, 18 (4), 1997) were dissolved in 0.2 to 2% acetic acid solution, removed impurities, neutralized with 30-50% NaOH until precipitation no longer occurred, washed with distilled water Precipitate 1-2 times, adjust the pH value to be neutral, wash the precipitate with distilled water several times, soak in acetone for 24-48 hours, filter, and dry at 40-60°C to obtain refined chitosan. The degree of deacetylation of chitosan was determined to be 75% to 98%, and the molecular weight was 15,000 to 210,000 (viscosity average molecular weight).

[0026] Get 10.5 grams of refined chitosan,...

Embodiment 2

[0029] N, N-diethyl-N-alkyl chitosan chlorinated or brominated quaternary ammonium salt and N, N-diethyl-N-aryl chitosan were prepared by chlorinated or brominated quaternary ammonium salt.

[0030] The preparation steps for the preparation of N-alkyl or N-arylated chitosan derivatives are the same as in Example 1. N, N-diethyl-N-alkyl chitosan chlorination or bromide quaternary ammonium salt and N, N-diethyl-N-aryl chitosan chlorination or bromide quaternary ammonium salt preparation process is : The chitosan derivative of 15 gram N-alkyl or N-arylation that will obtain is dispersed in the N-alkyl-2-pyrrolidone of 630ml, after room temperature swelling 12 hours, add NaOH (1.3mol / L ) and CH 3 CH 2 Cl or CH 3 CH 2 I (0.3mol), add NaI to the reactant system to make the concentration 0.2mol / L. After stirring the reaction at 50°C for 15 hours, add acetone to the reactant system until no precipitation is formed in the solution, and the precipitated N,N-diethyl-N-alkyl chitosan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com