Highly oriented laminated dihydroxy composite metal oxide film and its preparing method

A layered double hydroxyl, oxide film technology, applied in oxide/hydroxide preparation, chemical instruments and methods, single crystal growth, etc. Advanced problems, to achieve the effect of simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Polystyrene was hot-pressed into sheets, soaked in commercially available concentrated sulfuric acid for 3 days, rinsed with deionized water, and dried at 40°C for later use.

[0044] In a 1000mL reaction vessel, 1.923gMg(NO 3 ) 2 ·6H 2 O and 1.407gAl(NO 3 ) 3 9H 2 O was dissolved in 750 mL of deionized water to prepare a solution with a total metal ion concentration of 0.015 mol / L. After adding 6.306g of urea and dissolving it, suspend the surface sulfonated polystyrene sheet horizontally in the solution, seal the container, and react at a constant temperature of 70°C for 9 days. After the solution was cooled, the polystyrene sheet was taken out, rinsed with deionized water, and dried at 40°C for 24 hours.

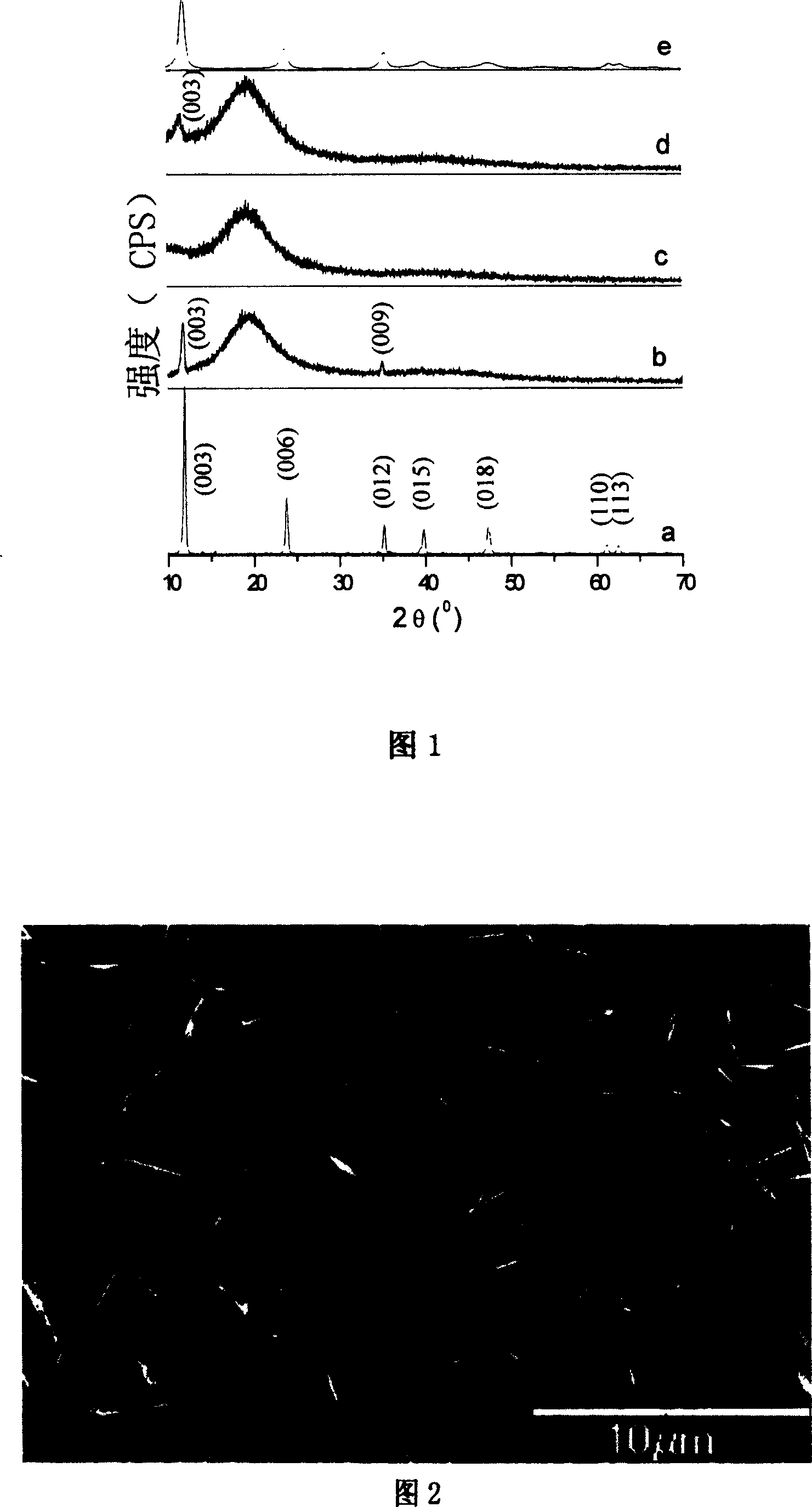

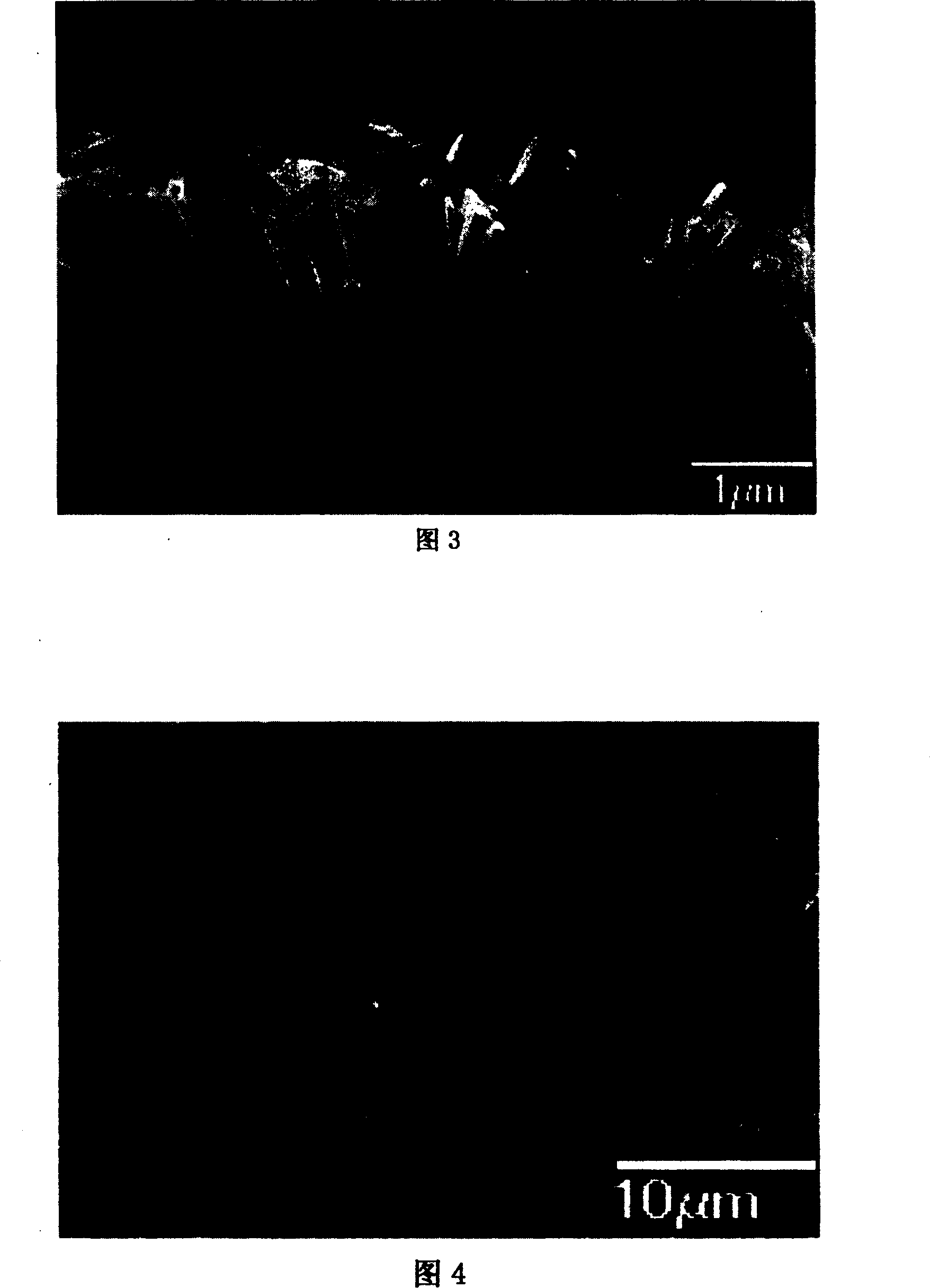

[0045] The film formed on the surface of polystyrene is magnesium aluminum carbonate LDHs film, the molar ratio of Mg / Al in the film is 1.61, and the content of Al on the film surface is 0.0143mol / m 2 . Its XRD spectrum is shown in Figure 1(b), and the FESE...

Embodiment 2

[0047] Polystyrene was hot-pressed into sheets, soaked in commercially available concentrated sulfuric acid for 3 days, rinsed with deionized water, and dried at 40°C for later use.

[0048] In a 1000mL reaction vessel, 0.288gMg(NO 3 ) 2 ·6H 2 O and 0.141gAl(NO 3 ) 3 9H 2 O was dissolved in 750 mL of deionized water at a molar ratio of 4:1 to prepare a solution with a total metal ion concentration of 0.002 mol / L. After adding 0.608g of urea and dissolving it, suspend the surface sulfonated polystyrene sheet horizontally in the solution, seal the container, and react at a constant temperature of 60°C for 12 days. After the solution was cooled, the polystyrene sheet was taken out, rinsed with deionized water, and dried at 40°C for 24 hours.

[0049] The film formed on the surface of polystyrene is the magnesium aluminum carbonate LDHs film obtained. The Mg / Al molar ratio in the film is 1.84, the film thickness is about 1.70 μm, and the Al content on the film surface is 0.0...

Embodiment 3

[0051] Styrene-divinylbenzene copolymer was hot-pressed into sheets, soaked in commercially available concentrated sulfuric acid for 5 days, rinsed with deionized water, and dried at 30°C for use.

[0052] In a 1000mL reaction vessel, 1.923gMg(NO 3 ) 2 ·6H 2 O and 1.407gAl(NO 3 ) 3 9H 2 O was dissolved in 750 mL of deionized water to prepare a solution with a total metal ion concentration of 0.015 mol / L. After adding 6.306g of urea and dissolving it, suspend the surface sulfonated styrene-divinylbenzene copolymer substrate horizontally in the solution, seal the container, and react at a constant temperature of 90°C for 3 days. After the solution was cooled, the styrene-divinylbenzene copolymer sheet was taken out, rinsed with deionized water, and dried at 50°C for 24 hours.

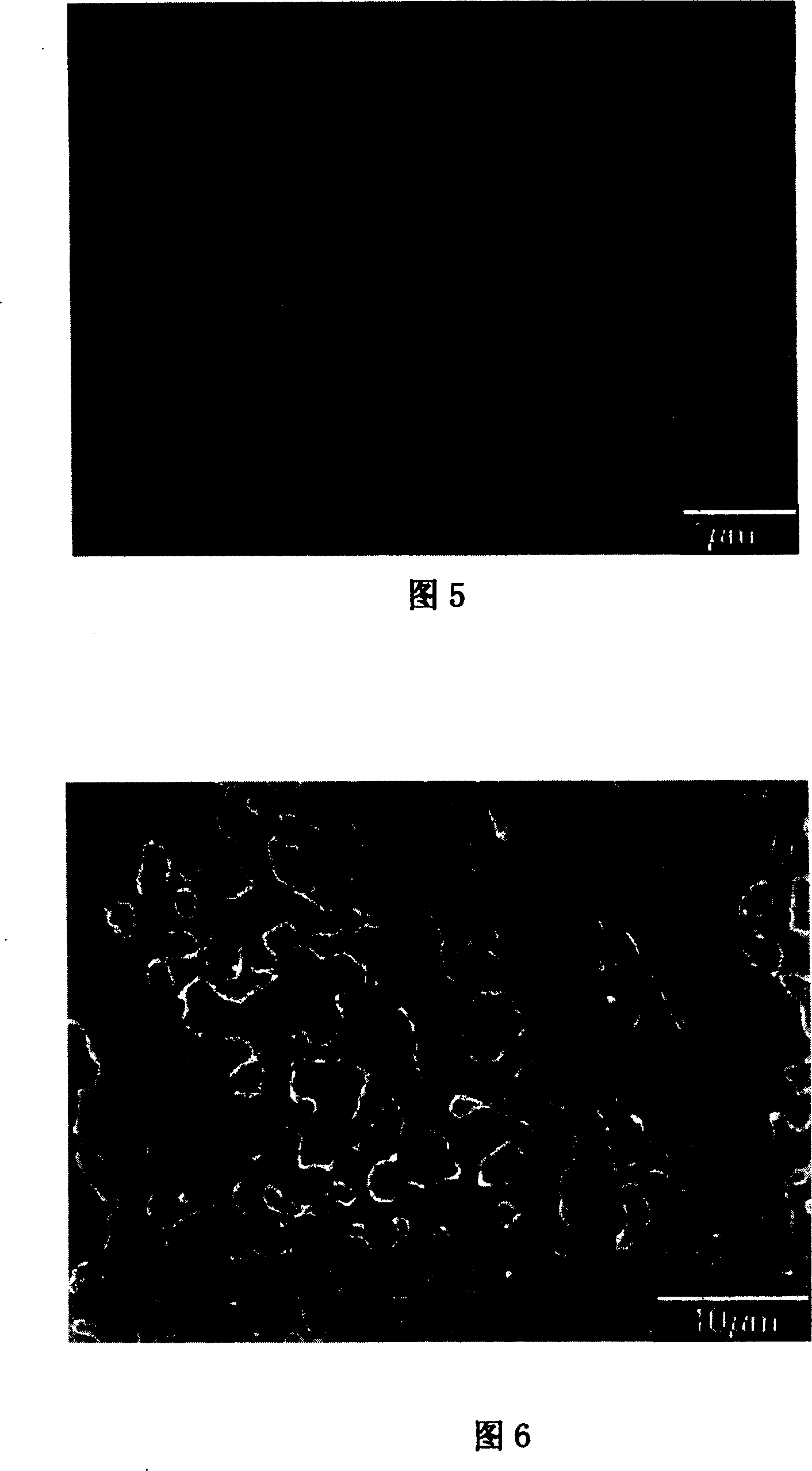

[0053] The film formed on the surface of styrene-divinylbenzene copolymer is the obtained magnesium aluminum carbonate LDHs film. The Mg / Al molar ratio in the film is 1.66, and the Al content on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com