Multicomponent composite liquid fertilizer

A multi-component and compound liquid technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of unreasonable ratio of nutrient elements, unstable products, narrow use range, etc., and achieve revitalization of physiological functions and enhancement of storability. The effect of transportation capacity and ratio is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

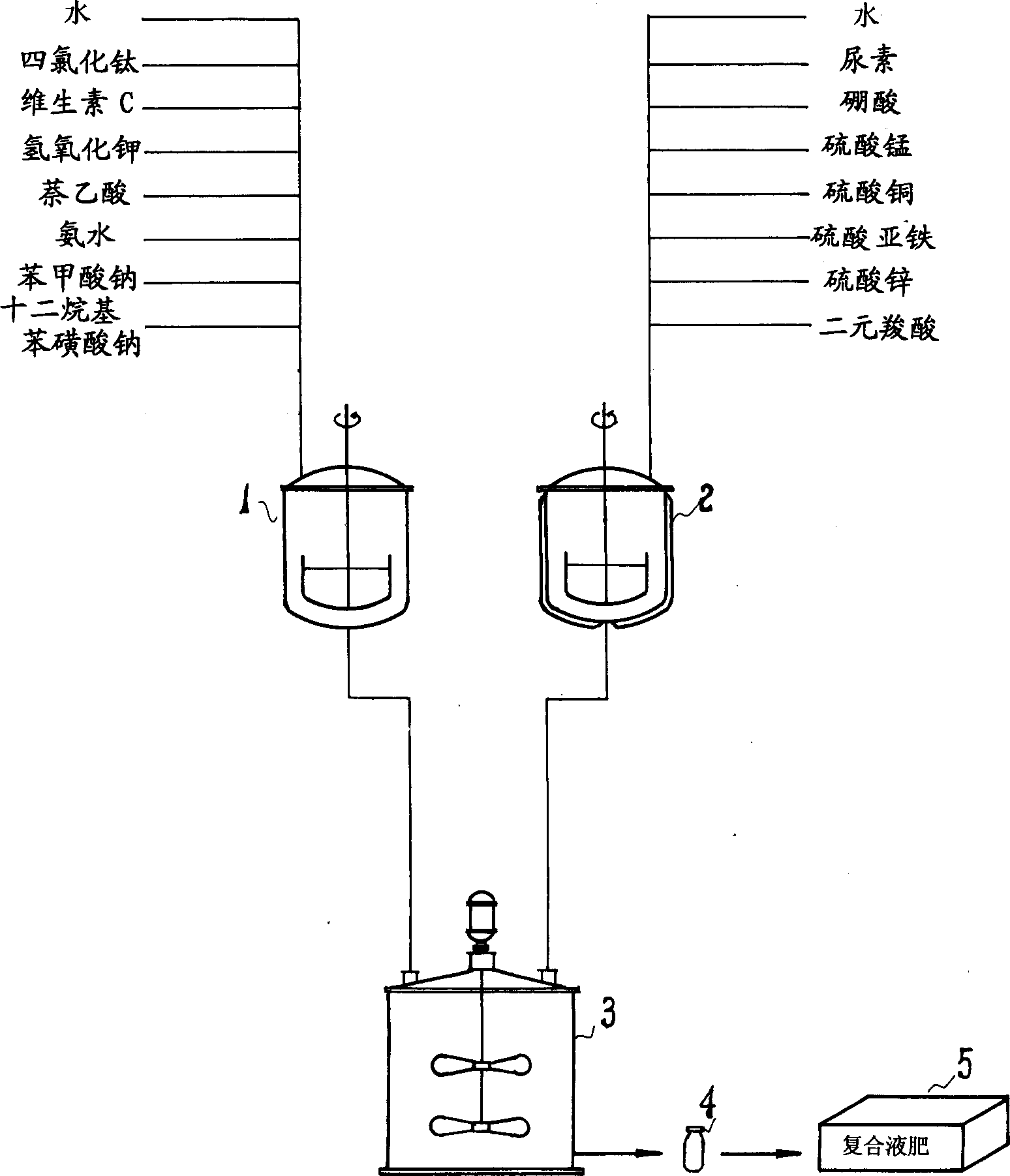

Image

Examples

Embodiment 1

[0050] Raw material ratio (by weight):

[0051] Titanium tetrachloride 9kg

[0052] Vitamin C 35kg

[0053] Ammonia 36kg

[0054] Potassium hydroxide 5kg

[0055] Naphthaleneacetic acid 0.6kg

[0056] water 450kg

[0057] Production method: first add water to the main ingredient kettle 1, start the agitator, weigh vitamin C and titanium tetrachloride respectively and add them to kettle 1, then weigh potassium hydroxide and naphthaleneacetic acid and add them to the kettle in turn After 1, add ammonia water into the kettle, stir and mix until the pH value of the solution in kettle 1 reaches 3 to 4, release the solution in the kettle, and pack it into 50 grams or 100 grams or 200 grams per bottle after inspection. After bottle 4, finally pack into packing case 5 and be product.

Embodiment 2

[0059] Raw material ratio (by weight):

[0060] Titanium tetrachloride 9kg

[0061] Vitamin C 36kg

[0062] Ammonia 36kg

[0063] Potassium hydroxide 4kg

[0064] Naphthaleneacetic acid 0.5kg

[0065]Sodium Benzoate 1.3kg

[0066] Sodium dodecylbenzenesulfonate 1kg

[0067] water 400kg

[0068] Production method: the previous process is the same as that of Example 1, first add water into the main ingredient kettle 1, start the agitator, weigh vitamin C, titanium tetrachloride, potassium hydroxide, and naphthaleneacetic acid and add them to the kettle 1 in sequence Finally, add ammonia water, when the pH value of the solution in the mixing tank reaches 3 to 4 after stirring, add sodium benzoate and sodium dodecylbenzenesulfonate respectively and stir and mix evenly. After inspection, 50 grams per bottle or 80 After gram or 100 grams or 200 grams are packed into bottle 4, pack into outer packing case 5 at last and be product.

Embodiment 3

[0070] Raw material ratio (by weight):

[0071] Titanium tetrachloride 8kg

[0072] Vitamin C 30kg

[0073] Ammonia 36kg

[0074] Potassium hydroxide 4.5kg

[0075] Naphthaleneacetic acid 0.4kg

[0076] Sodium Benzoate 1.4kg

[0077] Sodium dodecylbenzenesulfonate 0.8kg

[0078] Urea 152kg

[0082] Zinc sulfate 86kg

[0083] 4,5,6 carbon dicarboxylic acid 45kg

[0084] Water 700kg

[0085] Production method: as attached figure 1 As shown, first add 140kg of water into the main ingredient kettle 1, start the agitator, weigh vitamin C, titanium tetrachloride, potassium hydroxide, and naphthaleneacetic acid respectively and add them to the kettle 1 in sequence, and then add ammonia water to make the kettle Solution pH value reaches 3~4, then adds sodium benzoate, sodium dodecyl benzoate respectively, finally adds 76kg urea and stirs and mixes to carry out stable complexation to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com