Low-temp. extrusion/jet-stacking forming process of structure engineering carrier frame

A tissue engineering and forming technology, applied in the field of product forming technology, can solve the problems of difficult to form a controllable pore structure, difficult to realize the forming of pore gradient structure and material gradient structure, difficult process methods, etc. Wide range of material adaptability, the effect of maintaining biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

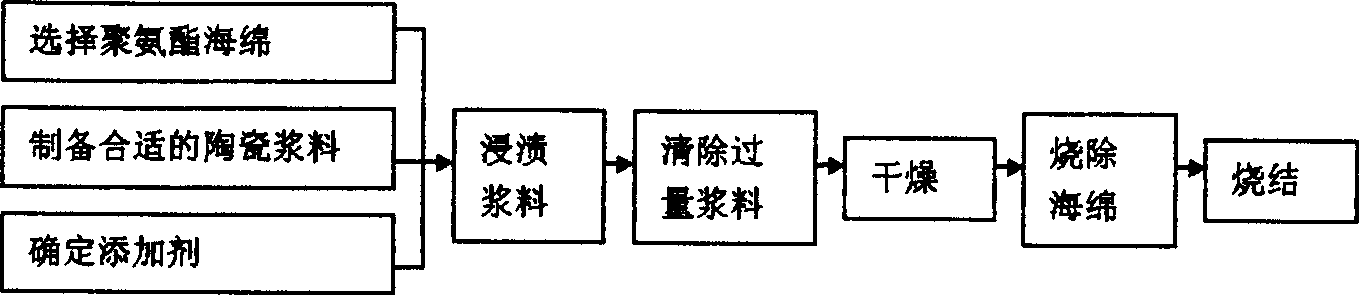

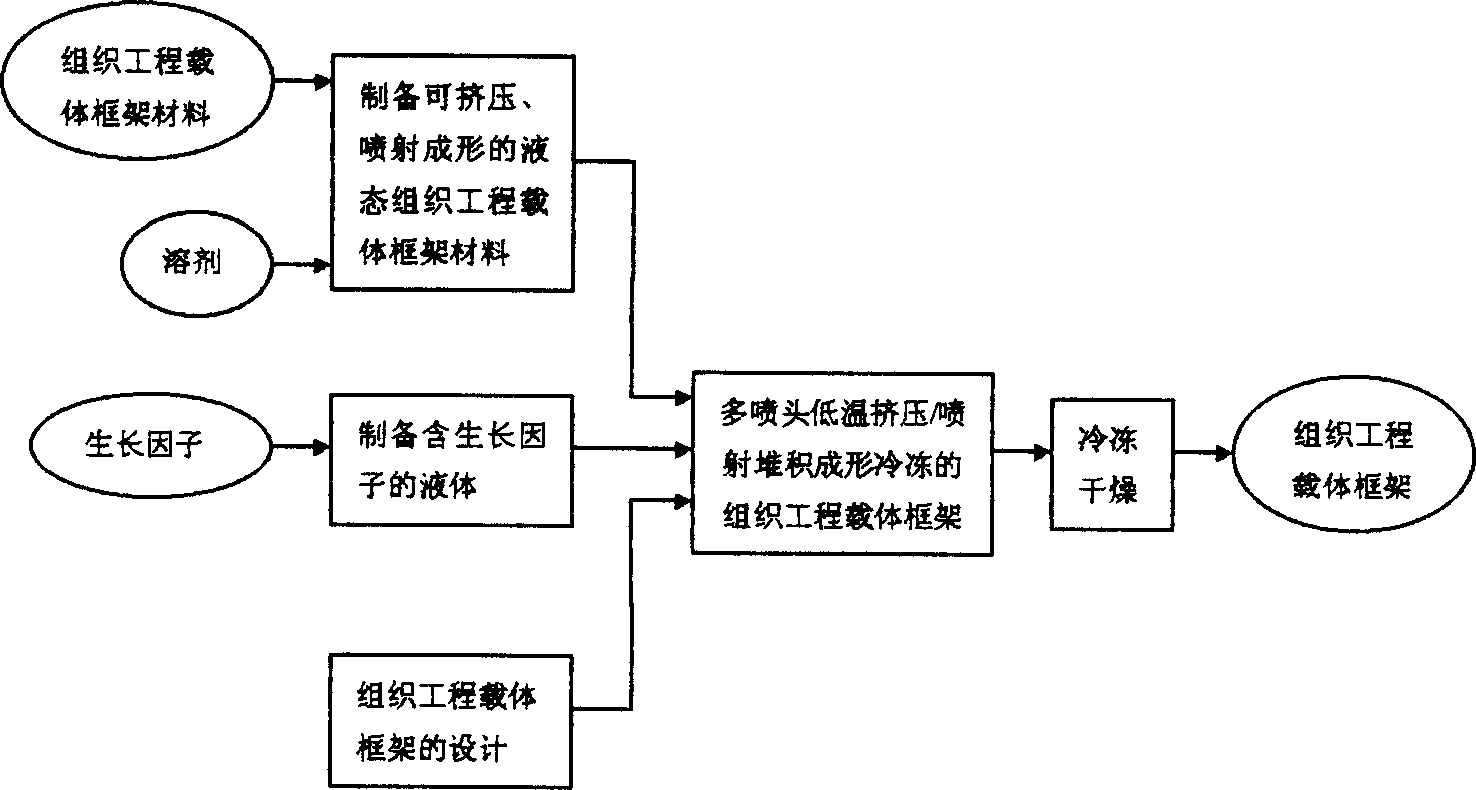

Method used

Image

Examples

Embodiment

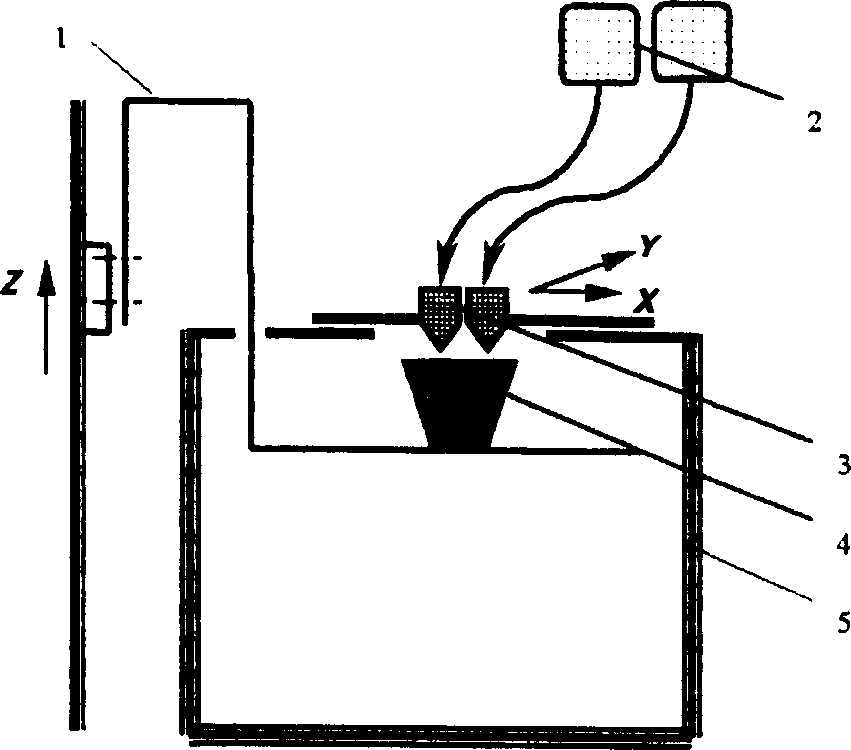

[0031] An embodiment of the present invention is a bone tissue engineering carrier frame manufactured by a low-temperature extrusion / spray deposition forming process, such as Figure 4 shown. The bone tissue engineering material used is a mixture of biodegradable high molecular polymer and calcium phosphate salt, and the growth factor used is bone morphogenetic protein. First, the bone tissue engineering material and chloroform were mixed to prepare a liquid slurry, and at the same time, an aqueous suspension of bone morphogenetic protein was prepared, and then the two liquid raw materials were put into two storage tanks, respectively Special nozzles convey raw materials. Under the control of the computer, the nozzle extrudes / sprays the two materials in a low-temperature forming room below 0°C, and builds them up layer by layer to obtain a frozen bone tissue engineering carrier frame. After freeze-drying, the obtained Figure 4 Tissue carrier frame structure shown. Under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com