Polymer supercapacitor using gel polymer as electrolyte and its preparing process

A gel polymer and supercapacitor technology, which is applied in the direction of hybrid capacitor electrolyte, capacitor parts, capacitor electrolyte/absorbent, etc., can solve the problems of liquid supercapacitors, such as difficult packaging and leakage, and achieve good environmental stability and Long service life, easy assembly, and high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

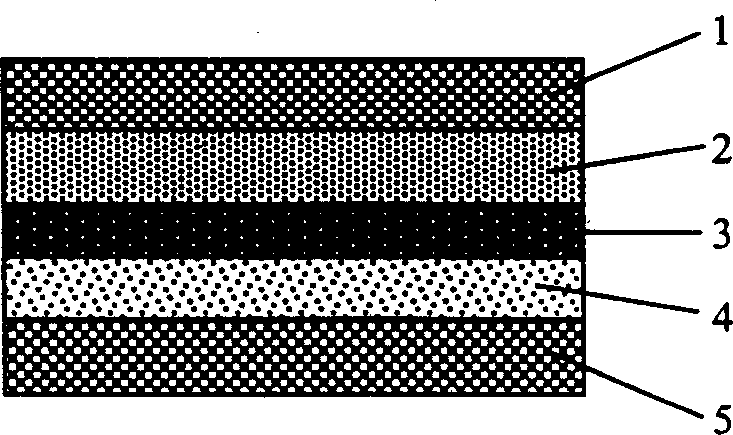

Image

Examples

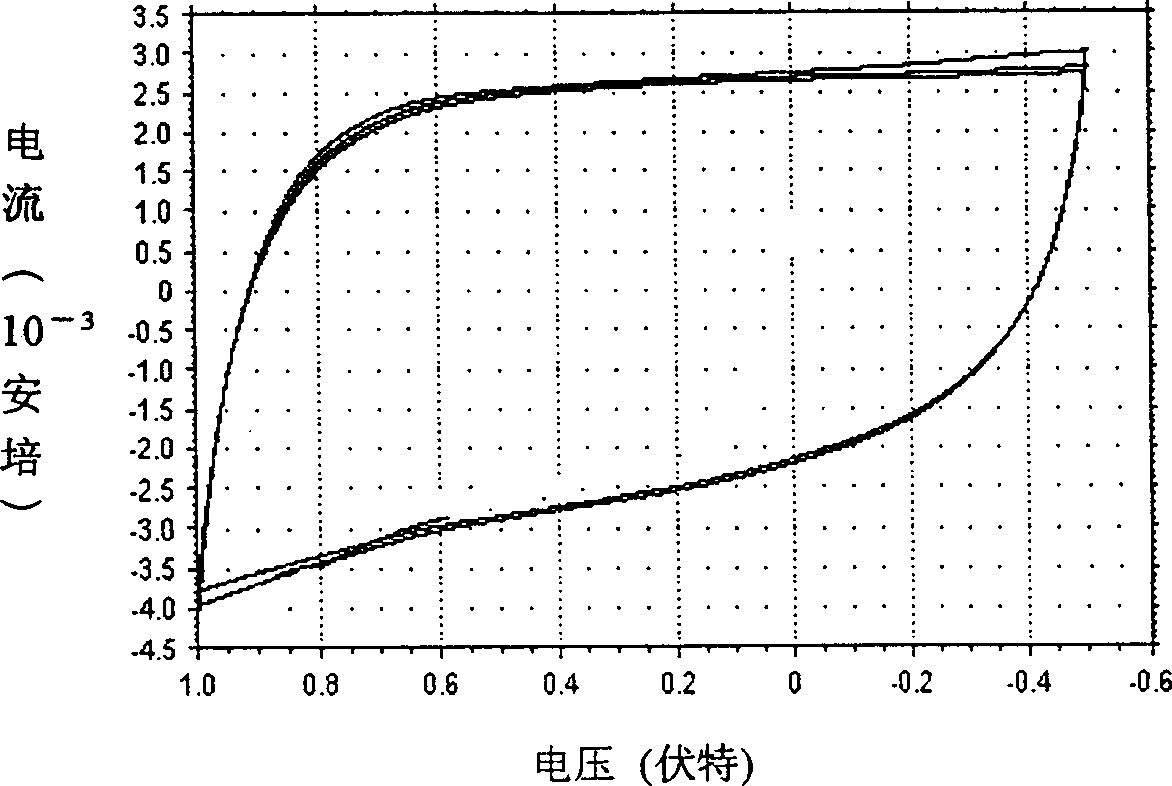

Embodiment 1

[0034] ①.Synthesis of polymethylthiophene

[0035] Propylene glycol carbonate as solvent, supporting electrolyte (Bu) 4 NPF 6 The concentration of methyl thiophene is 0.02M / L, the concentration of methyl thiophene is 0.1M / L, and the system is kept within the range of 5±2°C. The three-electrode method is used for polymerization, and stainless steel is used as the working electrode and the counter electrode, and the silver / silver chloride electrode is Reference electrode, then filled with nitrogen gas for 10 minutes, constant current (j=2mA / cm 2 ) and cyclic voltammetry to synthesize polymethylthiophene. The polymerization time is 6000s.

[0036] ②. Polypyrrole

[0037] Propylene glycol carbonate as solvent, supporting electrolyte (Bu) 4 NPF 6The concentration of pyrrole is 0.02M / L, the concentration of pyrrole is 0.1M / L, the system is kept at 0°C, and the three-electrode method is used for polymerization. The stainless steel is used as the working electrode and the counte...

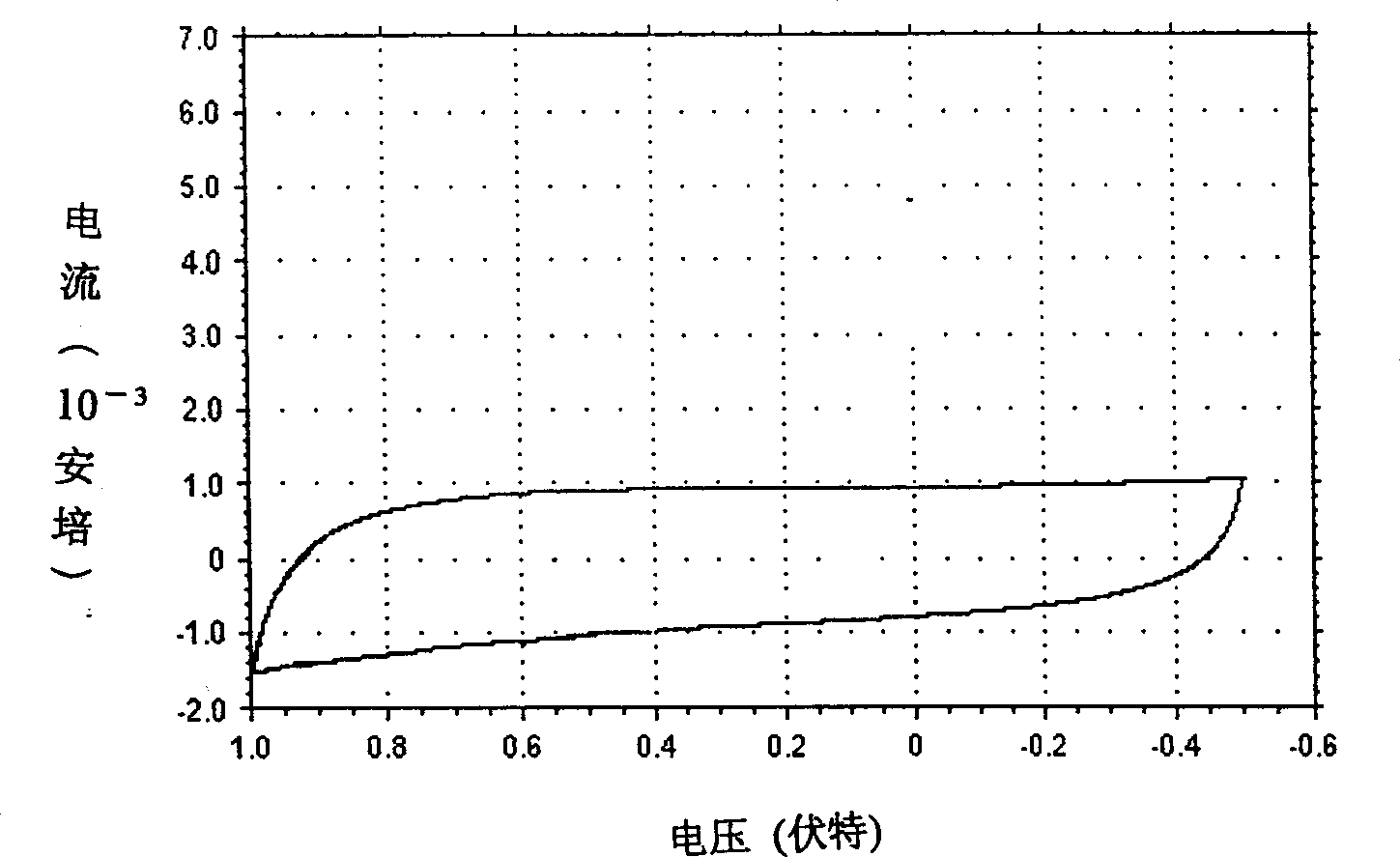

Embodiment 2

[0045] ①.Synthesis of methylthiophene-methoxythiophene copolymer

[0046] With propylene carbonate as solvent, tetrabutylammonium hexafluorophosphate (Bu) with a concentration of 0.02M / L 4 NPF 6 To support the electrolyte, the total concentration of the mixture of methylthiophene and methoxythiophene (10:1) is 0.1M / L, the system is kept within the range of 5±2°C, and the three-electrode method is used for polymerization, with stainless steel sheet or carbon paper As the working electrode and the counter electrode, the silver / silver chloride electrode is used as the reference electrode, and then filled with nitrogen for 10 minutes, with a constant current (j = 0.1 ~ 10mA / cm 2 ) and cyclic voltammetry to synthesize methylthiophene-methoxythiophene copolymers, with a total polymerization time of 6000s.

[0047] ②. Polypyrrole

[0048] Propylene glycol carbonate as solvent, supporting electrolyte (Bu) 4 NPF 6 The concentration of pyrrole is 0.02M / L, the concentration of pyrro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com