Process for preparing bioactive peptide-silk fibroin peptide

A silk fibroin peptide and enzymatic hydrolyzate technology, applied in the field of food biology, can solve the problems of serious membrane pollution and difficult to realize industrialized production, and achieve the effects of high desalination rate, large processing capacity and mild separation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation of silk fibroin peptide powder with degree of hydrolysis (DH)=12%

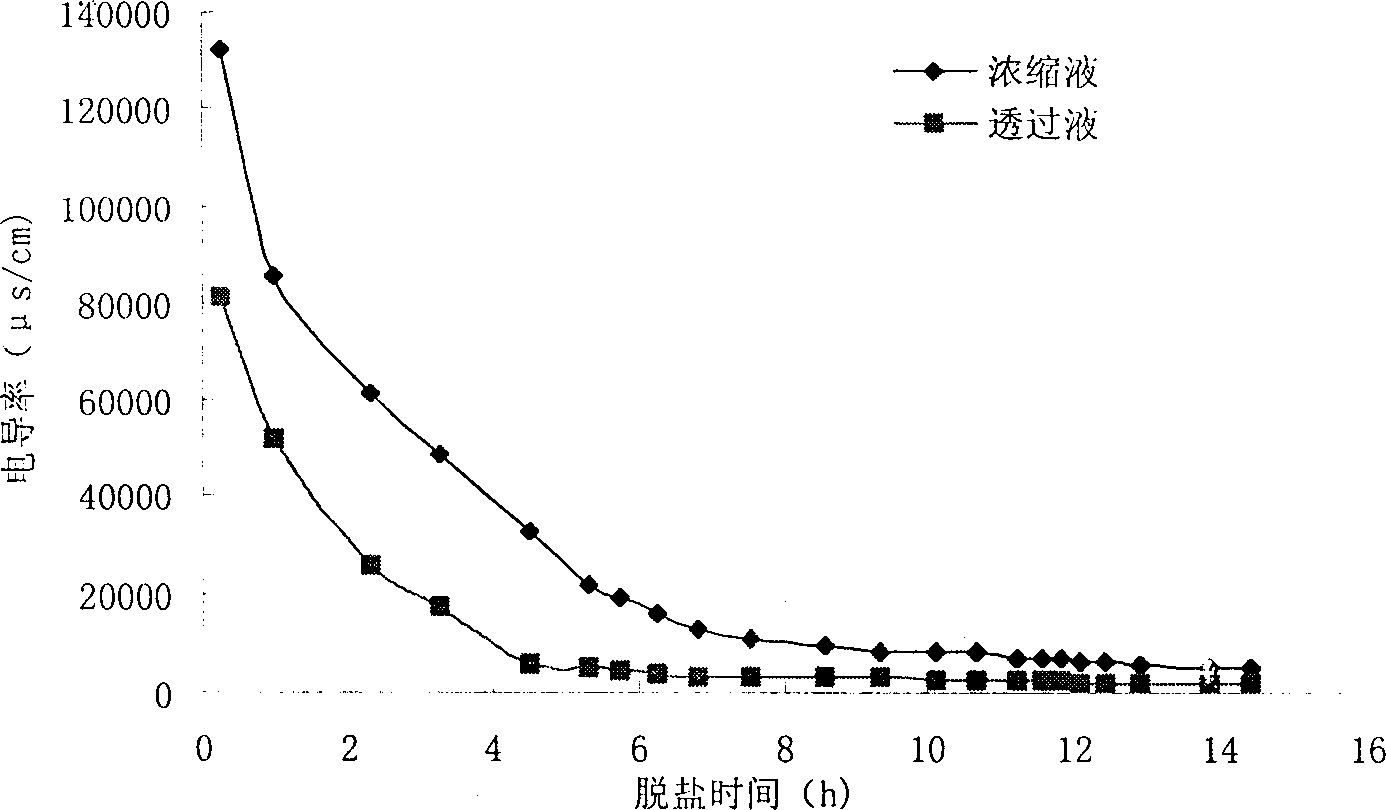

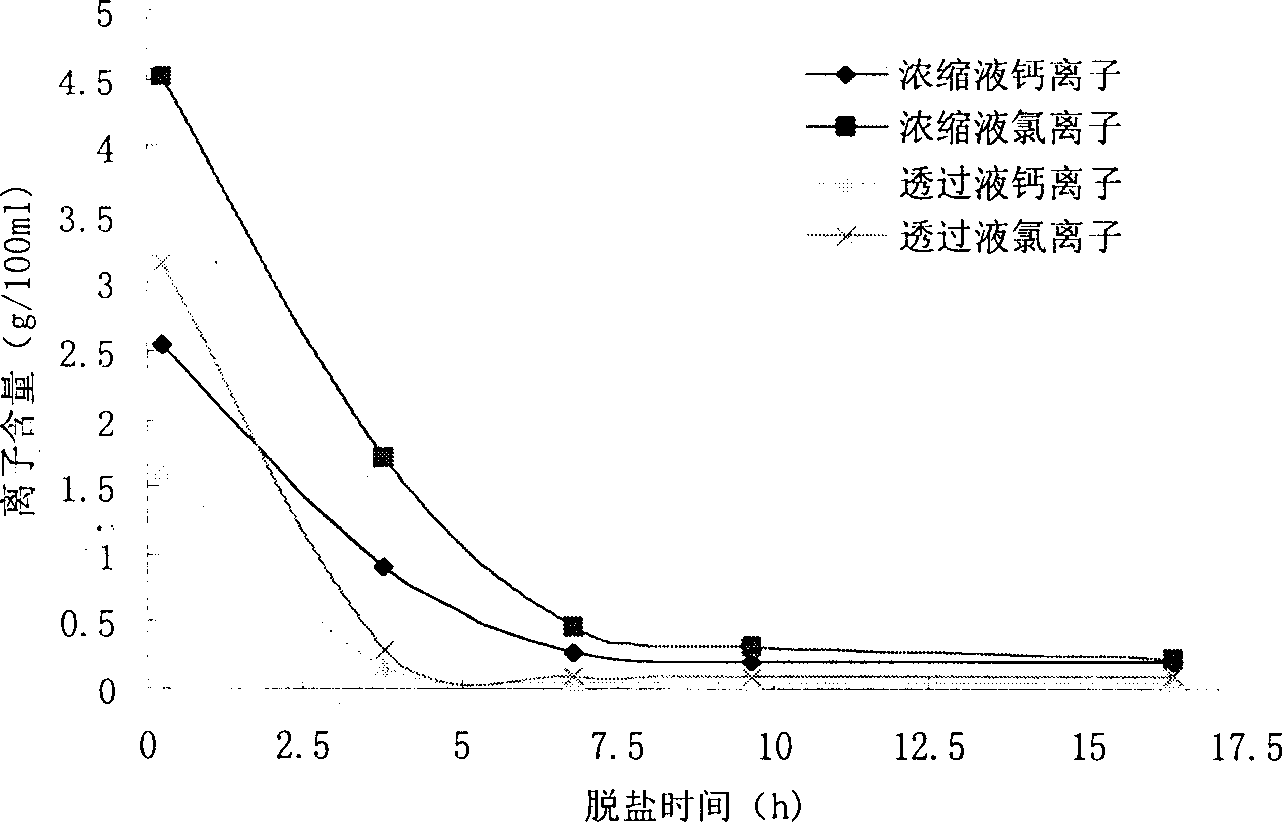

[0019] Waste silk (nodding) treated with 0.5% (w / v) Na 2 CO 3 After the solution is refined, place it in boiling 40% (w / w) CaCl 2 Dissolve in the solution for 5 minutes and 30 seconds (according to 100ml CaCl 2 The solution dissolves 14 g of scoured silk for dissolving), and cools rapidly. The silk-dissolving solution was filtered through gauze to obtain a concentrated silk-dissolving solution. Take 8 liters of the concentrated silk-dissolving solution, add 12 liters of water, carry out enzymatic reaction with Alcalase enzyme at pH 8.5 and 60°C, and use the pH-stat method to control the degree of hydrolysis. After the reaction is completed, the enzyme is heated to inactivate, centrifuged and filtered, and the filtrate is desalted with a polyamide nanofiltration membrane. During the desalination process, water is continuously added to dilute the feed solution, and the desalted feed solutio...

Embodiment 2

[0038] Preparation of silk fibroin peptide powder with degree of hydrolysis (DH)=10%

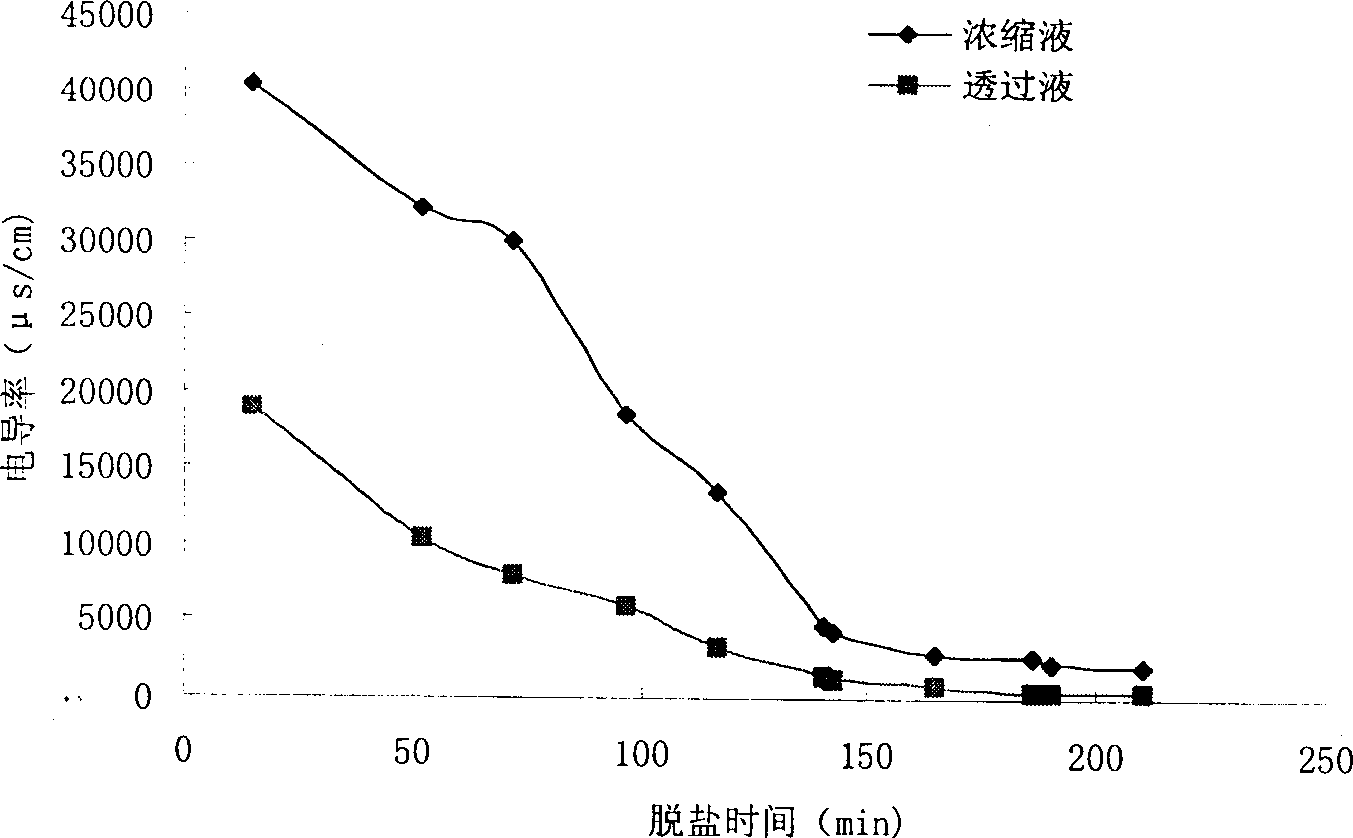

[0039] Waste silk (nodding) treated with 0.5% (w / v) Na 2 CO 3 After the solution is refined, place it in boiling 40% (w / w) CaCl 2 Dissolve in the solution for 5 minutes and 30 seconds (according to 100ml CaCl 2 The solution dissolves 14 g of scoured silk for dissolving), and cools rapidly. The silk-dissolving solution was filtered through gauze to obtain a concentrated silk-dissolving solution. Take 7 liters of the concentrated silk-dissolving solution, add 7 liters of water, carry out enzymatic reaction with Alcalase enzyme at pH 8.5 and 60°C, and use the pH-stat method to control the degree of hydrolysis. After the reaction is over, heat to inactivate the enzyme, and after centrifugation and filtration, the filtrate is desalted with a polyethersulfone nanofiltration membrane. During the desalination process, water is continuously added to dilute the feed solution. After desalination, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com