Assembled type compound array chip and its preparing method

An array chip and compound technology, applied in the field of assembled compound array chip and its preparation, can solve the problems of difficult reaction conditions, high cost, poor flexibility, etc., so as to improve the production accuracy, avoid mutual contamination, and reduce the production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

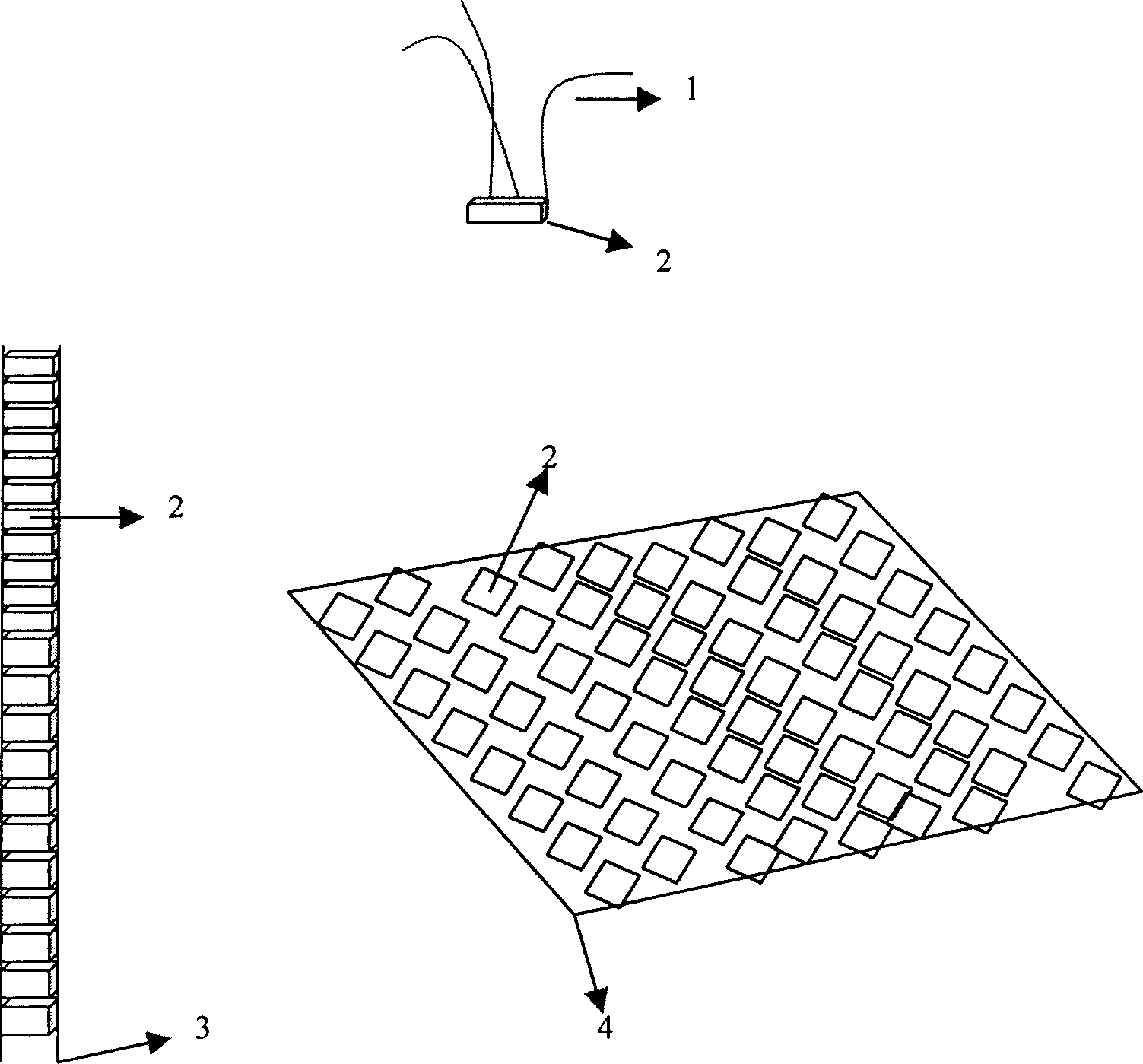

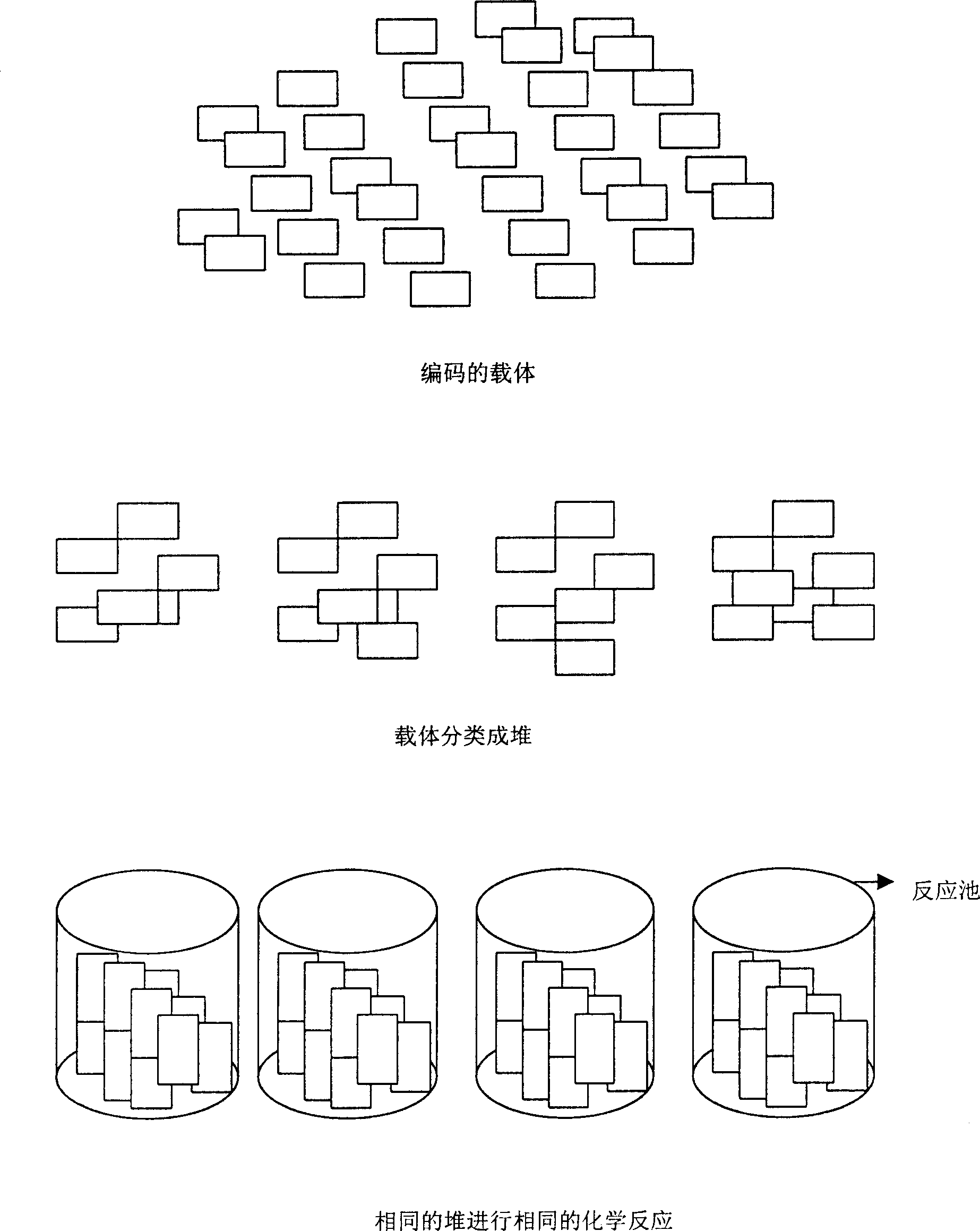

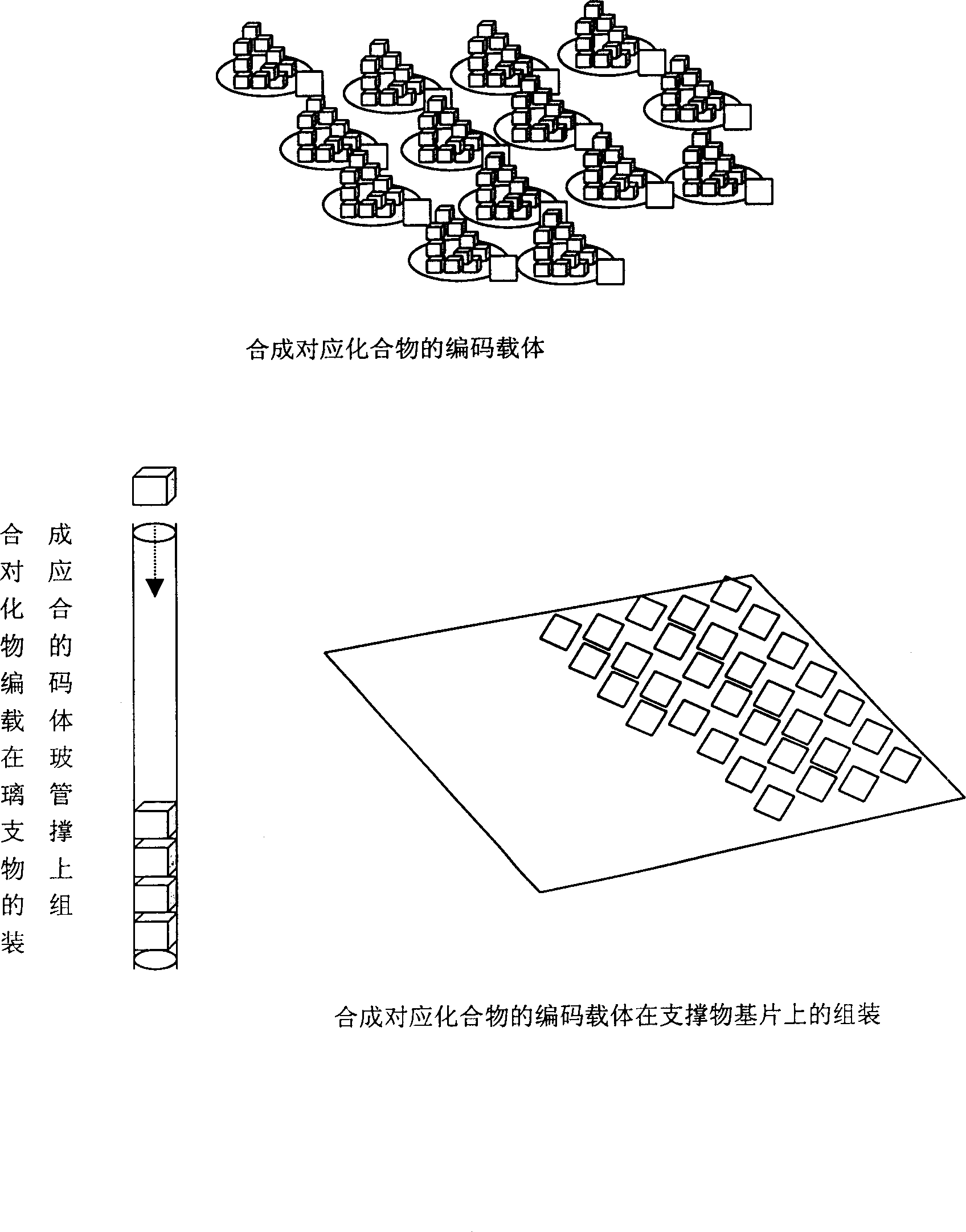

[0019]Example 1: Combinatorial synthesis of oligonucleotide compounds and preparation of compound array chips. After cleaning and drying the surface of the glass sheet, put it into a benzene solution of APTS (aminopropyltriethoxysilane) to react for 2 hours, rinse in benzene and then put it into a benzene solution of succinic acid to react for 1 hour, thereby Hydroxyl groups are formed on the glass surface. These glass flakes with hydroxyl groups on their surface were then coded. All coded glass slides were divided into four piles in a certain way. The first pile of glass slides was prepared in anhydrous acetonitrile containing dAdp and tetrazole (catalyst) whose 5'-OH was protected with di-p-methoxytriphenylmethyl (DMT). The coupling reaction is carried out in the first reaction pool of the solution, and the hydroxyl group on the surface of the glass sheet is coupled to the base A. dGdp and tetrazole (catalyst) in the second reaction cell of anhydrous acetonitrile solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com