High-dielectric composite material containing carbon nanotube and its prepn process

A technology of carbon nanotubes and composite materials, which is applied in the field of high dielectric materials, can solve the problems of lack of toughness, limited use, and low flexibility of materials, and achieve the effects of good material toughness, lower molding temperature, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 A1-A5

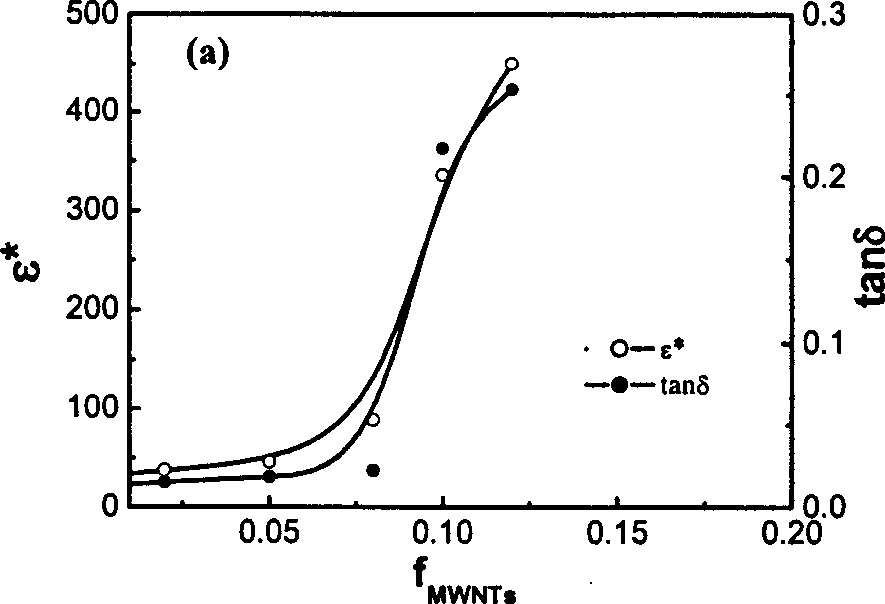

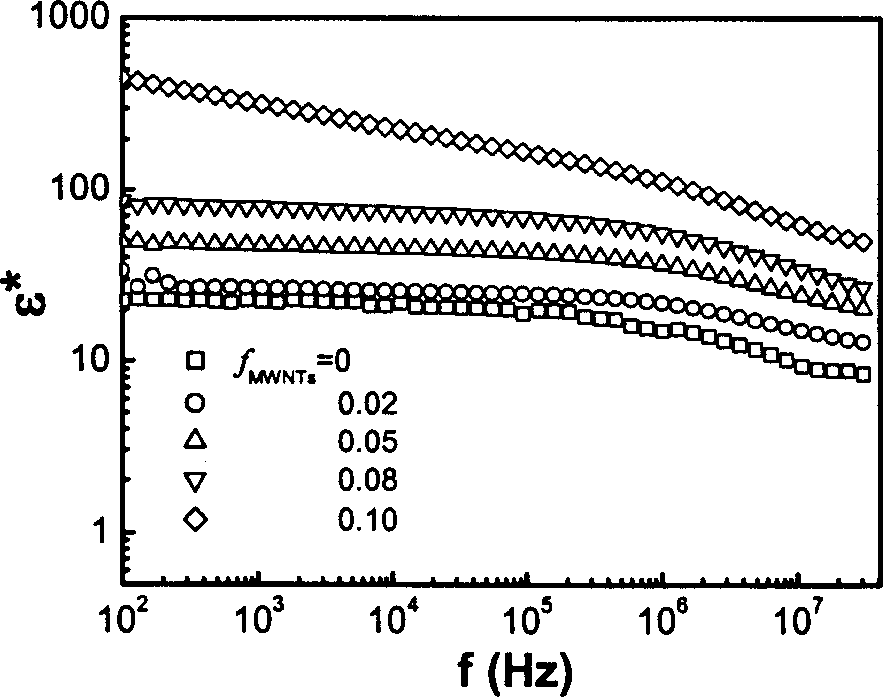

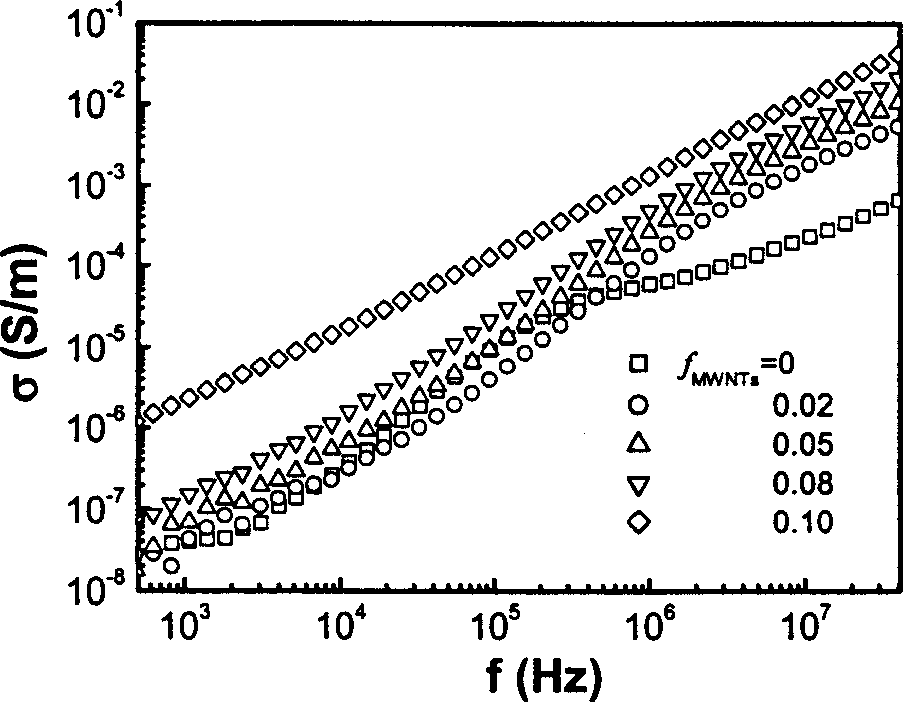

[0027] Different CNT according to the ratio of A1-A5 in Table 1 and 20vol.%, 0.5852 grams of BaTiO 3 , the three are fully mixed evenly, and hot-pressed on a hot press at 200°C (pressure 10MPa, time 20min) to form a series of samples, which are as follows: figure 1 The characteristic curves of the shown dielectric properties and dielectric loss, and the relationship curves of the dielectric constant (a) and conductivity (b) in Fig. 2 with the experimental frequency.

Embodiment 2

[0028] Example 2 A1-A5

[0029] The dielectric properties of the samples prepared in Example 1 as a function of the experimental temperature are shown in Figure 3. SEM of pristine carbon nanotubes as Figure 4 shown. The SEM morphology of the cross-section of the composite sample containing carbon nanotubes is as follows: Figure 5 shown.

[0030] Table 1 Ingredient formula

[0031] PVDF CNT

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com