Method for preparing spherical lighium manganate anode material of lighium ion batteries

A technology of lithium-ion batteries and spherical lithium manganese oxide, which is applied in the direction of electrode manufacturing, battery electrodes, active material electrodes, etc., can solve the problems of limited practical application, low specific capacity, and poor cycle performance, so as to improve cycle stability, Effect of high specific capacity and improved high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

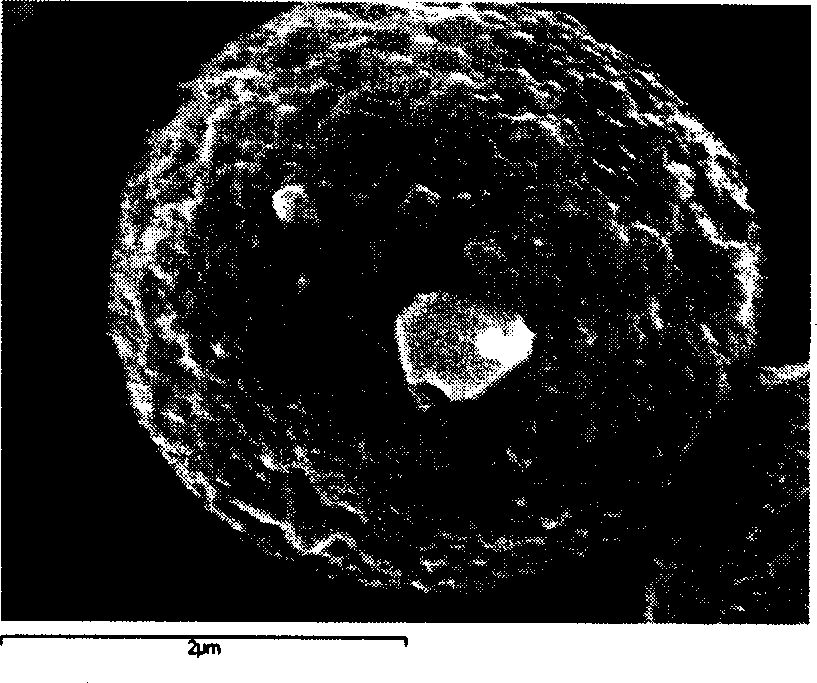

Image

Examples

Embodiment 1

[0032] Prepare MnSO with a concentration of 2.5 mol / L 4 Aqueous solution, prepared with 5 mol / L NaOH and 1 mol / L NH 3 mixed aqueous solution. Separately MnSO with a metering pump 4 , NaOH and NH 3 The mixed aqueous solution was input into a 3-liter volume reactor filled with deionized water in advance for reaction. Control MnSO 4 The flow rate of aqueous solution is 120ml / hour, adjust NaOH and NH 3The flow rate of the mixed solution is such that the pH value of the reaction solution in the reactor is 9.5±0.1. The temperature inside the reactor was controlled to be 45°C. The solid-liquid mixture in the reactor naturally overflows into the receiving tank. After feeding continuously for 20 hours, stop feeding, discharge the material in the reactor, and carry out solid-liquid separation with a centrifuge. Wash the solid product with deionized water at 60°C until the pH value of the washing water reaches 7-8. Dry the washed product in a drying oven at 80-100°C for 3-4 hour...

Embodiment 2

[0034] Prepare spherical Mn under the same conditions as in Example 1 3 o 4 . Weigh 24.2 g Li 2 CO 3 And measure 10 milliliters of deionized water, put it in a ball mill and stop it after 1 hour of ball milling. Weigh 100 grams of Mn prepared above 3 o 4 , into the ball-milled Li 2 CO 3 In the slurry, stir slowly for 5 minutes to obtain a mixed slurry. Put the mixed slurry into an alumina crucible, heat up to 750°C at a rate of 100°C / hour in a muffle furnace, keep the temperature constant for 20 hours, stop heating, and naturally cool to room temperature in the furnace to obtain spherical LiMn 2 o 4 product. The average particle size of the product was measured to be 8-10 μm, and the tap density was 2.28 g cm -3 . With lithium sheet as the negative electrode, the LiMn 2 o 4 The first discharge specific capacity at room temperature is 121mAh·g -1 .

Embodiment 3

[0036] With 2.5 mol / L Mn(NO 3 ) 2 Aqueous solution instead of MnSO 4 Aqueous solution, other conditions are identical with embodiment 1, prepare spherical LiMn 2 o 4 product. The average particle size of the product was measured to be 8-10 μm, and the tap density was 2.31 g cm -30 . With lithium sheet as the negative electrode, the LiMn 2 o 4 The first discharge specific capacity at room temperature is 127mAh·g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com