Contaminated soil heterotopic biological repairing method and special processing installation thereof

A contaminated soil and bioremediation technology, applied in the field of contaminated soil remediation, can solve the problems of secondary pollution of the environment and groundwater, and achieve the effect of simple structure, fast speed and optimized process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

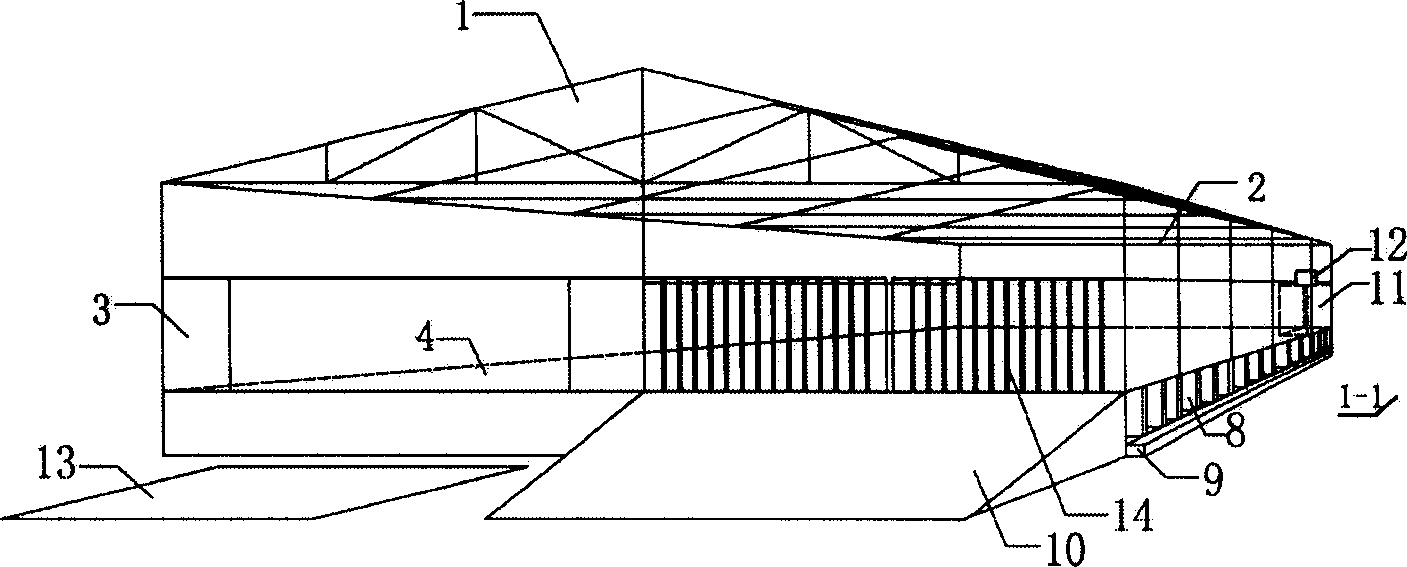

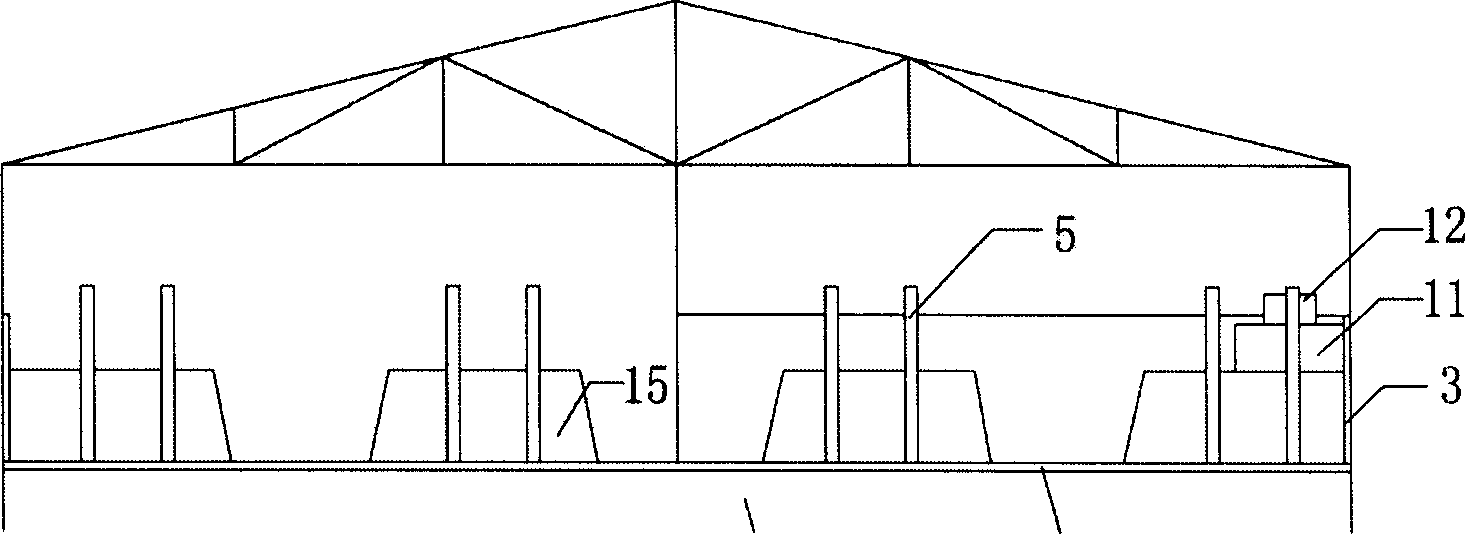

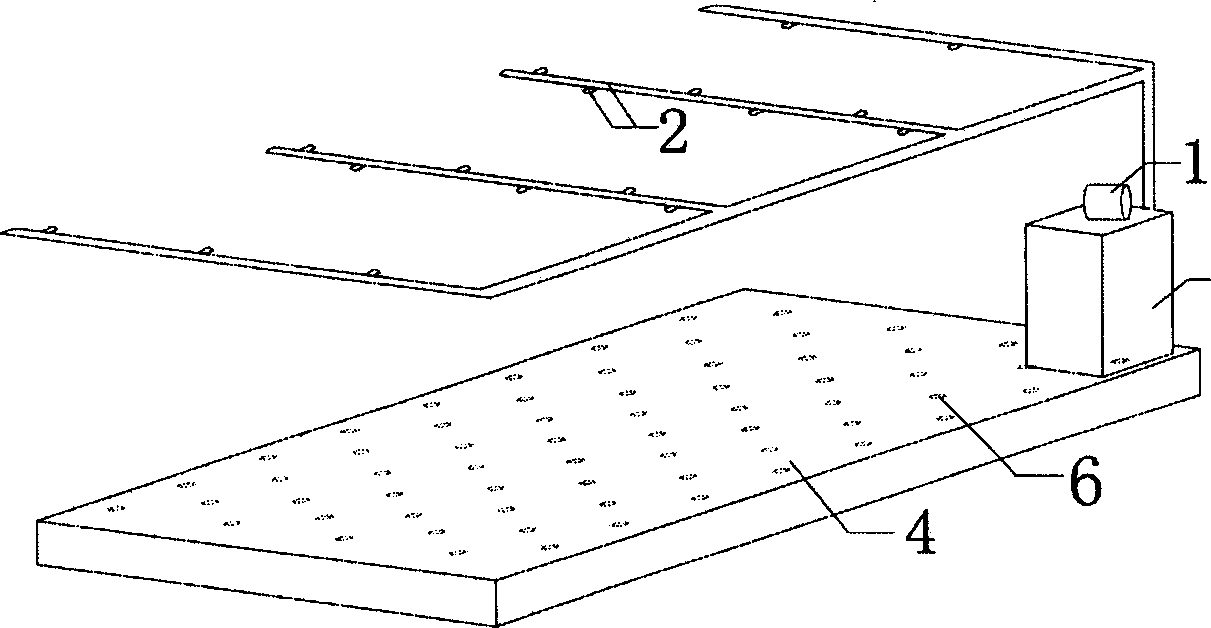

[0022] Such as figure 1 As shown, the special treatment facility of the inventive method mainly comprises baffle plate 3, prefabricated bed 4, vent pipe 5, air vent 6, air passage 8, anti-seepage layer 9, reservoir 11, mixing tank 13, and described prefabricated The bed 4 is made of stainless steel, the steel plate is 20m long, 10m wide, and 10mm thick. It is used for stacking pre-treated polluted soil. The baffle 3 is used as the side wall and has a ceiling 1, wherein: the baffle 3 is vertically installed around the prefabricated bed 4. The wall is 1m high and made of iron plate material. There is a space between the baffles 3, and there is a reinforced fence on it, connected to the ceiling 1. Its function is to prevent the polluted soil and floating dust from polluting the surrounding environment, and the reinforced fence plays a role of reinforcement; the prefabricated bed 4 The bed body is provided with vent holes 6—fancy drilled holes with a spacing of 0.2m and a hole dia...

Embodiment 2

[0049] The difference from Example 1 is:

[0050] In this embodiment, the ground crude oil near a certain oil well in Shenyang Oil Production Plant and the polluted soil around the oil well are excavated. The crude oil type is high pour point oil, and its density is 0.87~0.88g.cm -3 , the colloid+bitumen content is 11.5~24.3%, the wax content is 32.1~34.3%, the viscosity is 6.31~6.18mPa.s (100 ℃), the truck transports to the processing site, puts into the mixing pool 13, and the pretreatment pollution Add 219kg (2.8%) of organic fertilizer to the weight ratio of 7.3 tons of soil, and 219kg (2.8%) of solid bacterial agent. After fully stirring and evenly stacking on the prefabricated bed 4, 15 piles of polluted soil piles are 8m long, 2m wide, and 0.38m high. strips, with an interval of 0.5m between piles 2 The vertical air hole 6 is inserted into the air pipe 5 . During the treatment, pH and moisture were adjusted and controlled at 6.8 and 18.1%, respectively. The physical ...

Embodiment 3

[0067] The difference from Example 1 is:

[0068] In this embodiment, the ground crude oil near a certain oil well in Ciyutuo Oil Production Plant and the polluted soil around the oil well are dug up. The type of crude oil described is heavy oil, and its density is 0.93~0.96g.cm -3 , the colloid+bitumen content is 21.5~33.9%, the wax content is 4.2~7.4%, the viscosity is 566.6mPa.s (100 ℃), the truck is transported to the treatment site, puts into the mixing pool 13, and the polluted soil is pretreated as described Add 346kg (3.8%) of organic fertilizer in the weight ratio of 8.6 tons, and 215kg (2.3%) of solid bacterial agent, fully stir and stack on the prefabricated bed 4, and pile up 15 piles of polluted soil with a length of 8m, a width of 2m, and a height of 0.45m. Strip shape, with a stacking interval of 0.5m 2 The vertical air hole 6 is inserted into the air pipe 5 . During the treatment process, pH and moisture were adjusted and controlled at 8.0 and 16.8%, respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com