Composite solid polymer electrolyte for secondary lithium cell and preparing method thereof

An all-solid-state polymer, secondary lithium battery technology, applied in secondary battery parts and other directions, can solve the problems of increasing the reactivity with lithium anode materials, destroying the mechanical properties of electrolytes, reducing battery life, etc., and achieving high electrochemical stability. performance, low cost and high interfacial stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

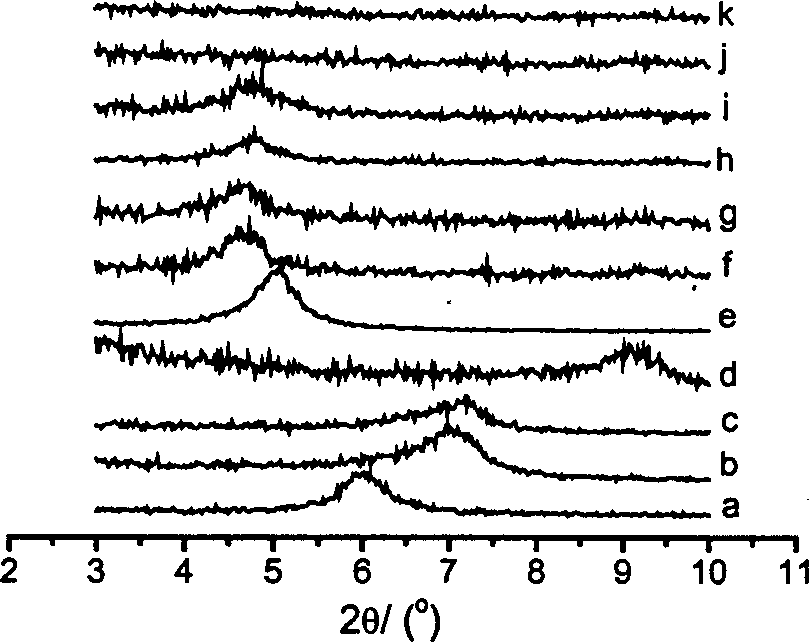

[0027] Example 1 PEO / LiClO 4 / modified montmorillonite

[0028] The montmorillonite used in this example is calcium-based montmorillonite, and the cation exchange capacity is 40 mmol per 100 grams. Firstly, calcium-based montmorillonite was modified with 1mol / L NaCl and 1mol / L LiCl, washed with deionized water, and dried in vacuum. mont and Li-mont. Part of the lithium-modified montmorillonite was vacuum-dried at 250°C for two days and recorded as 250-Li-mont. Dodecylamine-modified montmorillonite was prepared by adding dodecylamine to acidified sodium-based montmorillonite, and the sample was denoted as Org-mont. All samples were ground and passed through a 300-mesh sieve before use. The preparation of the composite polymer electrolyte membrane uses acetonitrile as a solvent and is prepared by a solution casting method. First, weigh a certain amount of PEO according to n(O) / n(Li)=16 (relative molecular mass is 3×10 5 ) and LiClO 4 , dissolved with acetonitrile, stirred...

Embodiment 2

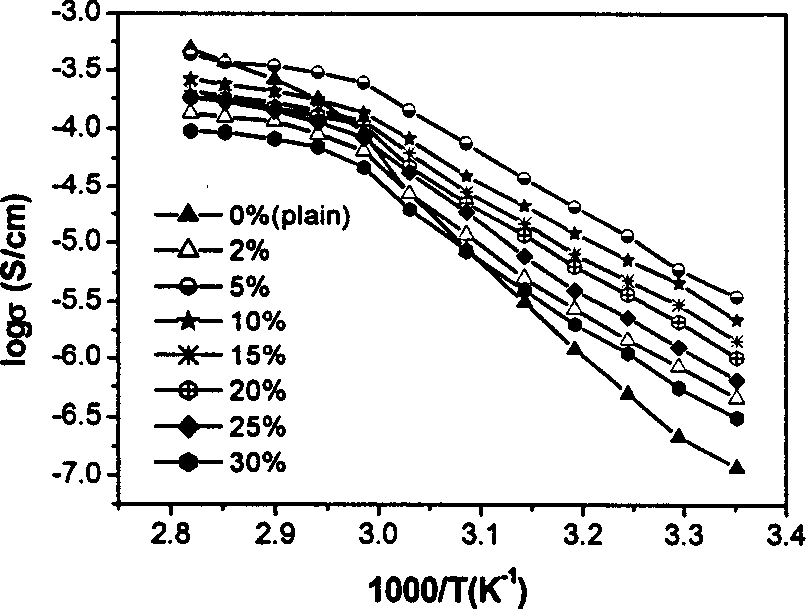

[0029] Example 2 PEO / LiClO 4 / ZnO in different forms (nano-scale, micro-scale and whiskers)

[0030] Nanoscale ZnO is synthesized by wet chemical method, and its average particle size is 60nm observed by TEM. The preparation of the composite polymer electrolyte membrane uses acetonitrile as a solvent and is prepared by a solution casting method. First, weigh a certain amount of PEO and LiClO according to the molar percentage of O / Li being 16 4 , and then add different mass percentages of n-ZnO (mass percentages account for PEO+LiClO according to n-ZnO 4 Calculate the mass of the powder), mix the powder evenly, dissolve it with acetonitrile, stir it in a conical flask for one day, and finally pour the solution on a tetrafluoro plate, evaporate the solvent, and then dry it in a vacuum oven at 80°C for two days. The thickness of the prepared electrolyte film is about 150 μm. The prepared samples were then tested for ionic conductivity ( Image 6 , Figure 7 ), thermal prope...

Embodiment 3

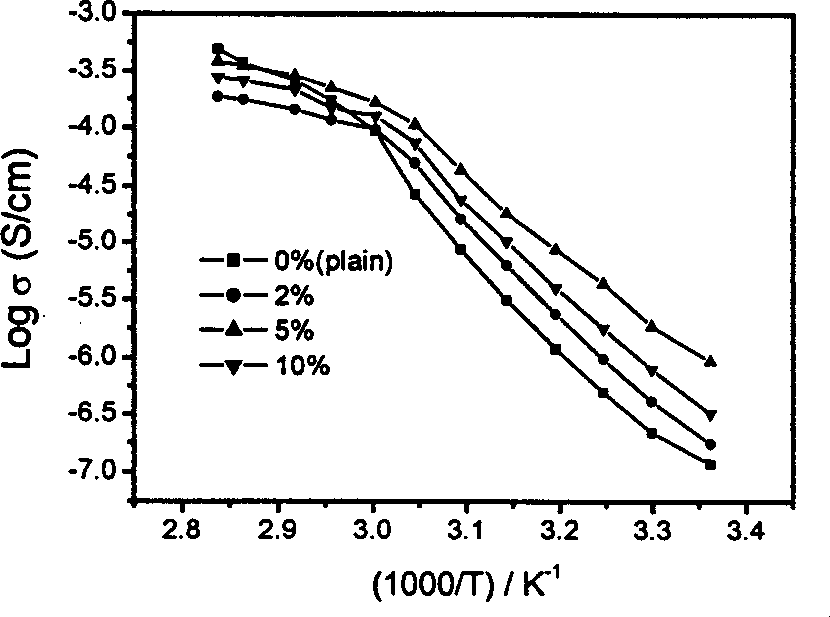

[0031]Example 3 PEO / LiClO 4 / Silane modified nano-SiO 2

[0032] There are four kinds of silane coupling agents: KH550, KH560, KH570 and KH792. Nanoscale SiO used 2 The powder particle size is about 10 nanometers, and the BET specific surface area is 249m 2 / g. Nanoscale SiO 2 Modification method: first dissolve a certain amount of silane coupling agent in alcohol, then add nano-scale SiO 2 , then stirred at room temperature for 24 hours, then stood still for 24 hours, filtered and then washed with alcohol to remove the silane coupling agent on the surface, and dried at 80°C for later use. The preparation of the composite polymer electrolyte membrane uses acetonitrile as a solvent and is prepared by a solution casting method. First, the modified SiO was dispersed by ultrasonic dispersion 2 Disperse in acetonitrile, then weigh a certain amount of PEO and LiClO according to the molar percentage of O / Li being 16 4 , Stir in the Erlenmeyer flask for one day, and finally p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com