Preparation technique of protein medicine microsphere carrier with small grain size

A protein and technology technology, which is applied in the field of preparation of protein drug microsphere carrier, can solve the problems of uneven particle size distribution, loss of protein activity, inconvenience of treatment, etc., and achieve the effect of uniform microsphere size, ensuring effectiveness and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] Raw material composition: 20mg / mLHb, 3% (wt / v) sodium alginate, 0.5% (v / v) Tween 20;

[0031] Gel bath composition: 2% (wt / v) CaCl2, 0.5% (wt / v) polyvinyl alcohol, 2% (v / v) Tween 20, 20% (v / v) propanol;

[0032] Output voltage: 250V;

[0033] Pulse frequency: 140Hz;

[0034] Pinhole inner diameter: 300μm;

[0035] Raw material liquid output speed: 10mL / hr;

[0036] The pressure is 0.15Mpa.

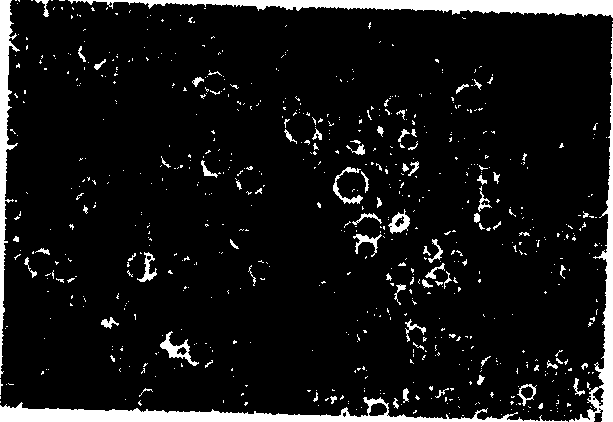

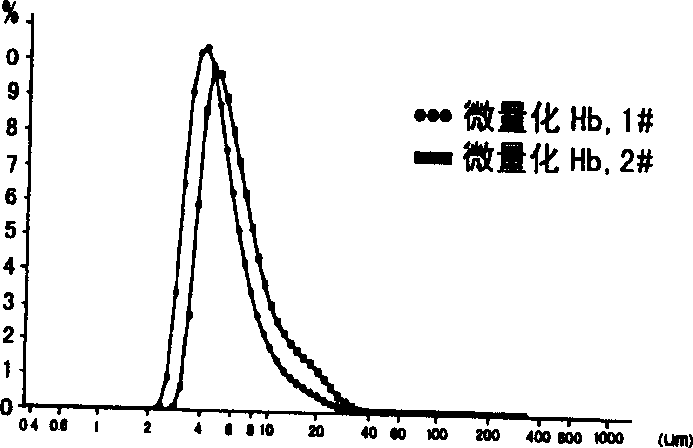

[0037] Under the above conditions, H-b-loaded microspheres with a particle size of ≤10 μm can be prepared, among which 3-7 μm microspheres account for more than 80%, and the size of the microspheres is uniform and the shape is good. The encapsulation efficiency of Hb in microspheres was 64%.

example 2

[0039] Raw material composition: 10mg / mLHb, 3% (wt / v) sodium alginate, 1% (v / v) Tween 80;

[0040] Gel bath composition: 2% (wt / v) BaCl 2 , 0.5% (wt / v) polyvinyl alcohol, 2% (v / v) Tween 80, 30% (v / v) propanol;

[0041] Output voltage: 275V;

[0042] Pulse frequency: 140Hz;

[0043] Pinhole inner diameter: 300μm;

[0044] Raw material liquid output speed: 10mL / hr;

[0045] The pressure is 0.05Mpa.

[0046] Under the above conditions, the average particle size of the prepared Hb-loaded microspheres was 6.9 μm, and the microspheres were uniform in size and good in shape. The encapsulation efficiency of Hb in microspheres was 67%.

[0047] According to the foregoing, it can be seen that the effect of the invention is:

[0048] 1. The present invention adopts the electrostatic liquid drop method microsphere preparation technology, which can prepare protein microsphere carriers with a microsphere particle size ≤ 10 μm and a narrow particle size distribution, such as figure 1 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com