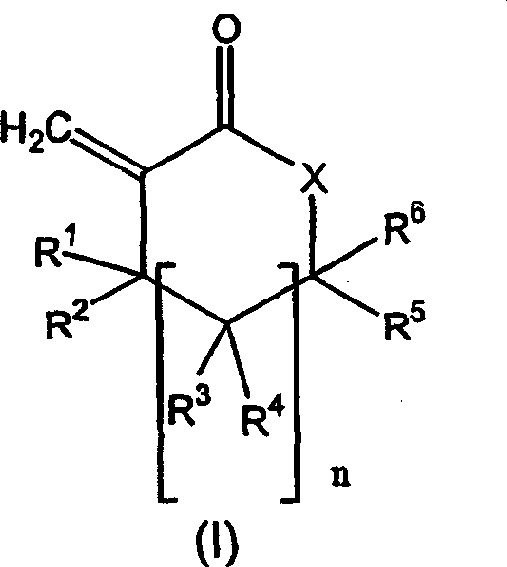

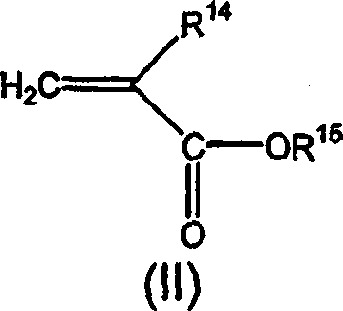

Alpha-methylene lactone homopolymer and copolymer compositions sheets and articles articles therefrom and the process for their manufacture

A technology of methylene lactone and composition, which is applied to the composition of α-methylene-lactone homopolymer and copolymer, the boards and products manufactured therefrom and the field of production thereof, can solve the problem of harming the environment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0113] Table 3 in Example 3 gives the experimentally determined modulus of elasticity. It has been found that the modulus of elasticity improves with increasing α-methylene-lactone content.

[0114] The filled polymer compositions described herein have a better refractive index match between the polymer and the filler because poly(MBL) has a higher refractive index compared to PMMA. This can produce materials with greater transparency.

[0115] All compositions herein may additionally comprise other materials commonly found in thermoplastic compositions, such as dyes, pigments, UV stabilizers, processing aids, flame retardants, antioxidants and antiozonants. These materials are present in conventional amounts, the amount added varying according to the type of material being added and the purpose for which it is being added.

[0116] It has been found that incorporation of the compositions of the present invention into solid surface materials results in the presence of antimi...

Embodiment 1-3

[0144] Preparation of Filled Plates Containing α-Methylene-g-Butyrolactone (Heat Curing)

[0145] In a reactor, three polymer slurries of a 10% by weight solution of poly(methyl methacrylate-ethyl acrylate) (96 / 4 by weight) in a MBL / MMA mixture were passed through slowly dissolving the polymers in a single Prepared in vivo. In the 100% MBL mix, during the degassing step, no acrylic smell was detected nor was there any foam or air bubbles. These pastes were used to make filled acrylic panels as described in Experiment 1. The plates were the same color as the plates in Experiment 1.

[0146] sample

[0147] nature

[0148] thermal properties

[0149] Tα is the highest relaxation temperature corresponding to the glass transition, Tβ and Tβ' are the adjacent lowest relaxation temperatures, which are thought to be the result of the movement of the lactone ring, and Tγ is the lowest measured relaxation temperature, which is thought to be -CH 3 resu...

Embodiment 4

[0151] Prepare filled plates containing methylene butyrolactone (chemically cured, 10 wt.

[0152] %MBL)

[0153] The following ingredients were added sequentially to a 2000 mL reactor equipped with a thermometer, air driven stirrer, rubber septum and reflux condenser:

[0154] tert-butylperoxymaleic acid 9.81g

[0155] Pearl gray pigment paste 0.91g

[0156] Dioctyl sodium sulfosuccinate 3.92g

[0157] Trimethylolpropane trimethacrylate 6.54g

[0158] MMA 56.22g

[0159] α-MBL 52.96g

[0160] 24% polymethylmethacrylate solution in MMA 544.6g

[0161] After mixing the ingredients for 1 minute at room temperature, 1020 g of ATH were added in portions over 2 minutes, followed by stirring for 10 minutes.

[0162] About 5.0 g of MMA was added. With stirring, the mixture was evacuated at 10 KPa. Vacuum down to 20KPa with stirring, then slowly heat to 40°C in a water bath. Rapidly inject the following ingredients in sequence:

[0163] Deionized water 2.04g

[0164] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com