Carbon material stuffing with low adhering index, coke briquette with the stuffing as main material and its production process

A technology of main raw material and cohesive index, applied in coking ovens, petroleum industry, etc., can solve problems such as cohesion, high ash content of coke powder, low strength, etc., and achieve the goal of saving coking coal resources, improving coke quality and coke ratio coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

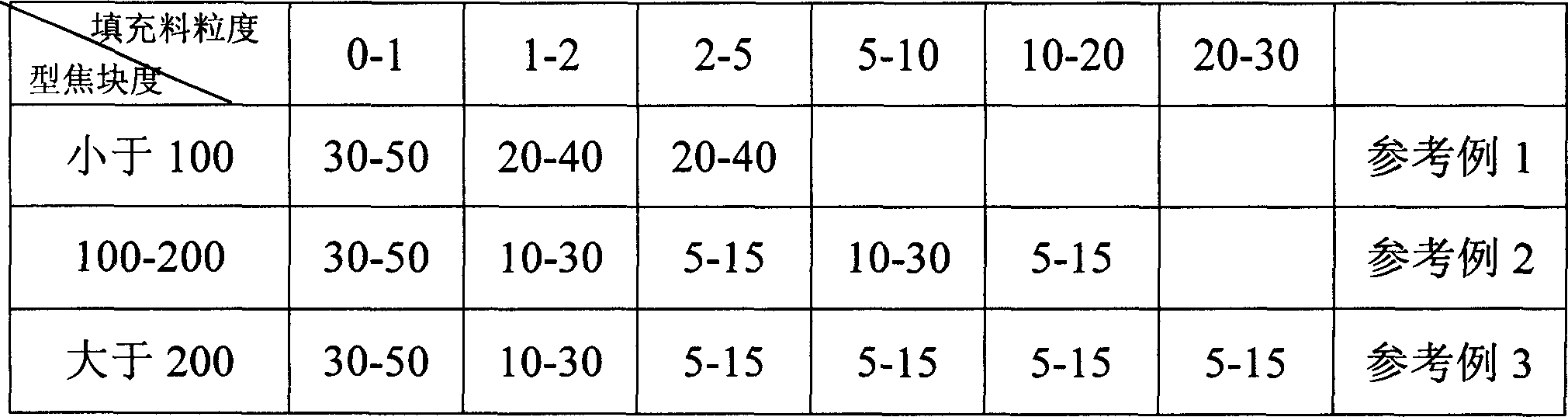

[0030] Example 1 Choose 100 tons of No. 2 anthracite, its cohesive index is 0, volatile content is 9%, ash content is 10%, and it is crushed to particles below 100mm, and it is used as raw filling material and put into the furnace for dry distillation at a temperature of 850-1000°C In 15 hours, 92 tons of fillers were obtained. After crushing the filling material, sieve it into six raw materials with different particle size grades as shown in Table 1 and save them for future use. This filler can be directly used as a blast furnace charring agent. It is also the main raw material for producing the coke of the present invention. Its physical and chemical indicators are 11% ash and 1.6% volatile matter.

Embodiment 2

[0031] Example 2 Select 20 tons of Shanxi Guxian No. 2 primary coking coal with a caking index of 84, 25% volatile content, and 8% ash content; 60 tons of calcined anthracite with a caking index of 0, 1.5% volatile content, and 10% ash content tons; 20 tons of calcined pitch coke with a cohesive index of 0, a volatile content of 1.3%, and an ash content of 0.5% were mixed and pulverized until the particle size was less than 100 mm, and 100 tons of raw filler were obtained.

[0032] Get the filler obtained in Example 1, carry out batching according to the classification reference data of Table 1 and the diameter of the coke block to be made, for example, the diameter of the coke block is designed to be 160mm, and between the reference data 100-200mm, refer to as listed in Table 1 Example 2 The range of ingredients is selected. Take 50 tons of filler and 10 tons of high-temperature asphalt and heat them separately. The heating temperature of the filler is 300°C, and the heating t...

Embodiment 3

[0033] Example 3 Select 60 tons of Shanxi Hongdong No. 2 fat coking coal with a caking index of 83, a volatile content of 34%, and ash content of 8%, and 40 tons of calcined coal with a caking index of 0, a volatile content of 1.4%, and ash content of 0.3%. Petroleum coke is mixed, the ash content of the mixture is 5%, the volatile content is 21%, the cohesive index is 30, and it is pulverized to a particle size below 100 mm to obtain 100 tons of raw filler.

[0034] Take the filler material obtained in Example 2 to produce spherical coke with a particle size of 135 mm, select a total of 60 tons of materials according to Reference Example 3 in Table 1, take 15 tons of petroleum pitch, mix the two and heat to 200 ° C to fully stir, and use 240 kg / cm 2 The press is pressurized and formed to produce a 75-ton coke green billet. Get 100 tons of raw fillers obtained in this example and mix them into a furnace for dry distillation. The furnace temperature is 900° C., the dry distil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com