Nutrient additive grain of edible fungus

A technology of nutritional additives and edible fungi, which is applied in the fields of application, horticulture, botany equipment and methods, etc., can solve the problems that the output of edible fungi cannot be greatly increased, the products lack market competitiveness, and the culture material is polluted, etc. Fast silk germination, increased yield, and strong vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

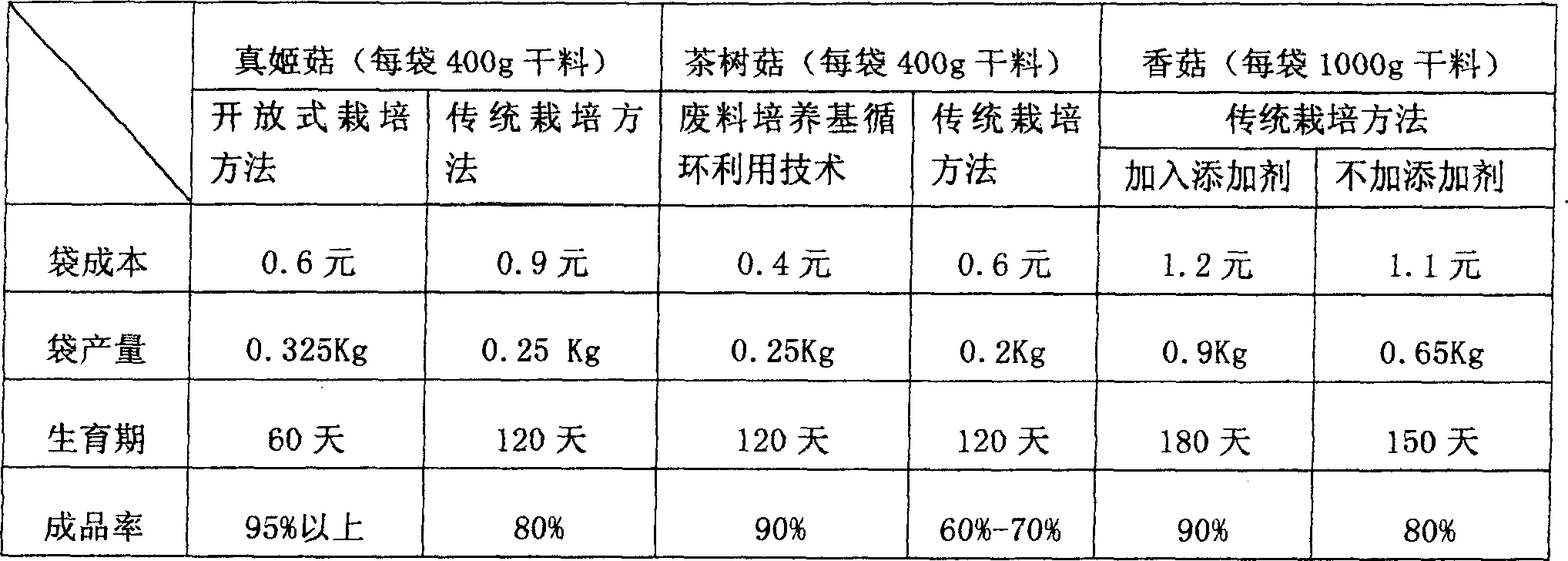

Image

Examples

Embodiment 1

[0015] Embodiment 1: when cultivating Pleurotus eryngii, select bean dregs, cottonseed dregs as the material containing crude protein, be pulverized into fine particles, and expand, mix with potassium dihydrogen phosphate, magnesium sulfate, vitamin B, E after pulverizing After being uniform, it is made into granules, wherein okara accounts for 70% (percentage by weight), cottonseed dregs accounts for 27.8% (percentage by weight), potassium dihydrogen phosphate accounts for 1% (percentage by weight), and magnesium sulfate accounts for 1% (percentage by weight). Vitamin B and E account for 0.2% (percentage by weight); the above-mentioned granules are first coated with a layer of wet starch, and then coated with miscellaneous sawdust powder or rice husk powder.

Embodiment 2

[0016] Embodiment 2: because the growth of shiitake mushroom requires lower fat content, therefore select the bean dregs with extremely low fat content as the material containing crude protein, it is pulverized into fine particles, and expanded, and potassium dihydrogen phosphate after pulverizing, After vitamin B1 is evenly mixed, it is made into granules, wherein bean dregs account for 91% (percentage by weight), potassium dihydrogen phosphate accounts for 7% (percentage by weight), and vitamin B1 accounts for 2% (percentage by weight); above-mentioned granules are first wrapped with a A layer of wet starch, and then wrapped in miscellaneous sawdust powder or rice husk powder.

[0017] When in use, the prepared nutrient additive granules are mixed with conventional culture materials in a certain proportion and can be used as culture materials for edible fungus cultivars.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com