Forming improved stabiity emissive layer from donor element in OLED device

A technology of stability and emission layer, applied in electrical components, electric solid-state devices, semiconductor devices, etc., can solve problems such as lowering stability, and achieve the effect of lowering working voltage, improving stability, and improving working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0134] Embodiment 1 (the embodiment of the present invention)

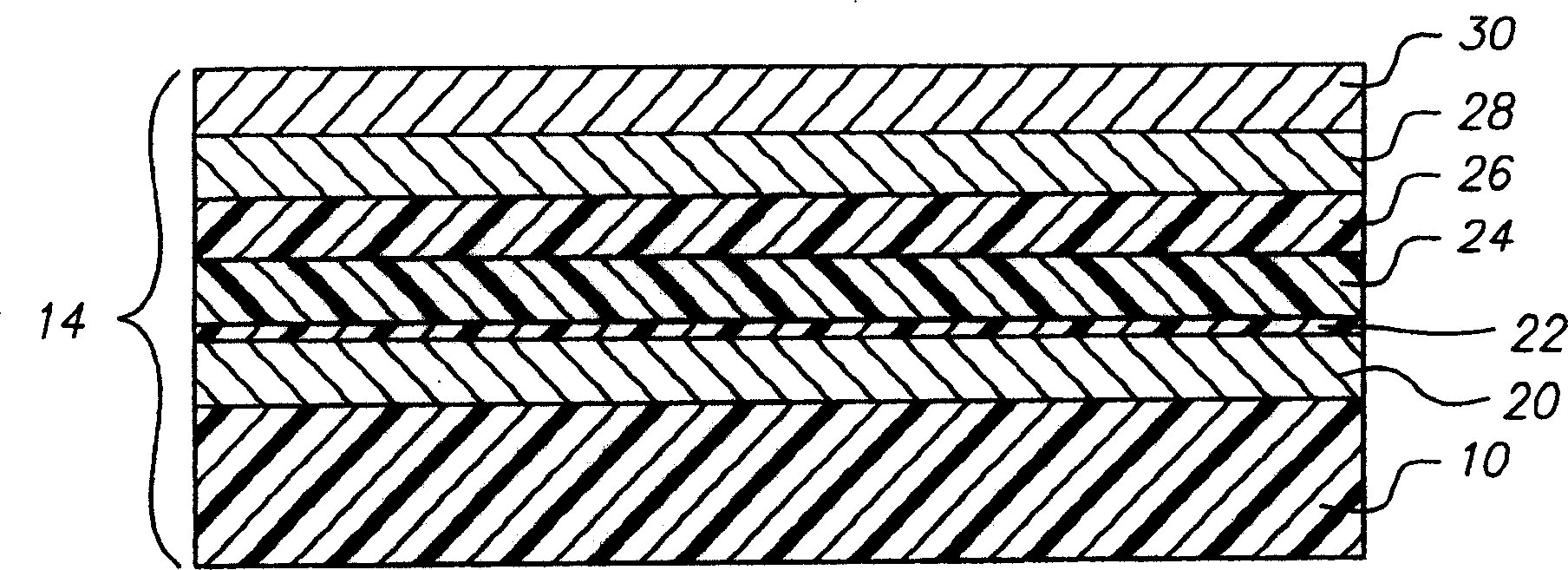

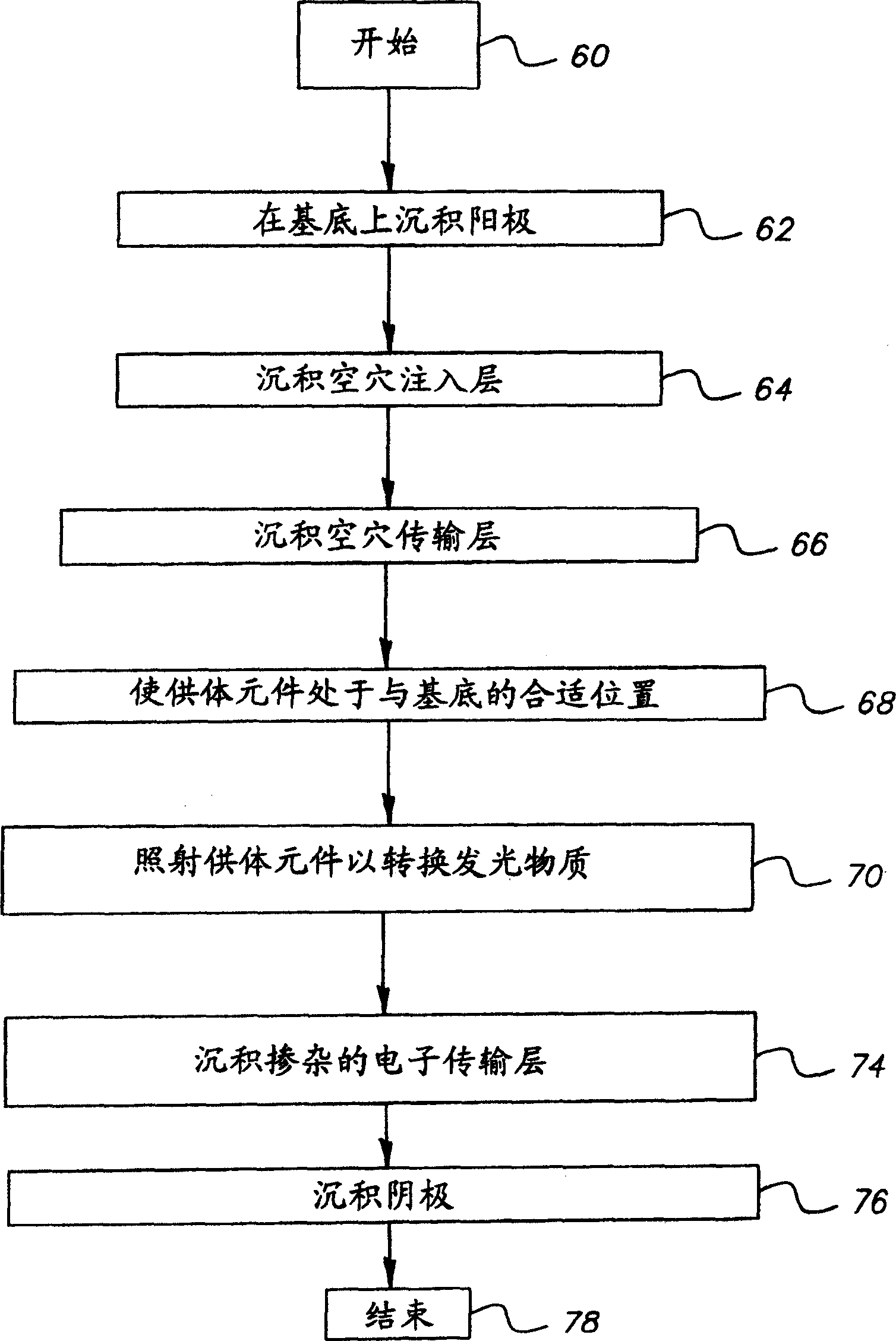

[0135] An OLED device meeting the requirements of the present invention and doped with an organic layer of a low work function metal is manufactured by the following method:

[0136] 1. Vacuum deposition of indium tin oxide (ITO) on a clean glass substrate to form a 34nm thick transparent electrode.

[0137] 2. The ITO surface prepared above was treated with plasma oxygen etching, followed by plasma deposition of a 1.0 nm layer of fluorocarbon polymer (CFx) as described in US-A-6,208,075.

[0138] 3. At about 10 -6 The substrate prepared above was further processed by vacuum deposition under Torr vacuum to deposit 170 nm 4,4'-bis[N-(1-naphthyl)-N-phenylamino]biphenyl (NPB ) hole transport layer.

[0139] 4. The substrate prepared above was removed from the vacuum and exposed to air for about 5 minutes before being placed in a nitrogen oven.

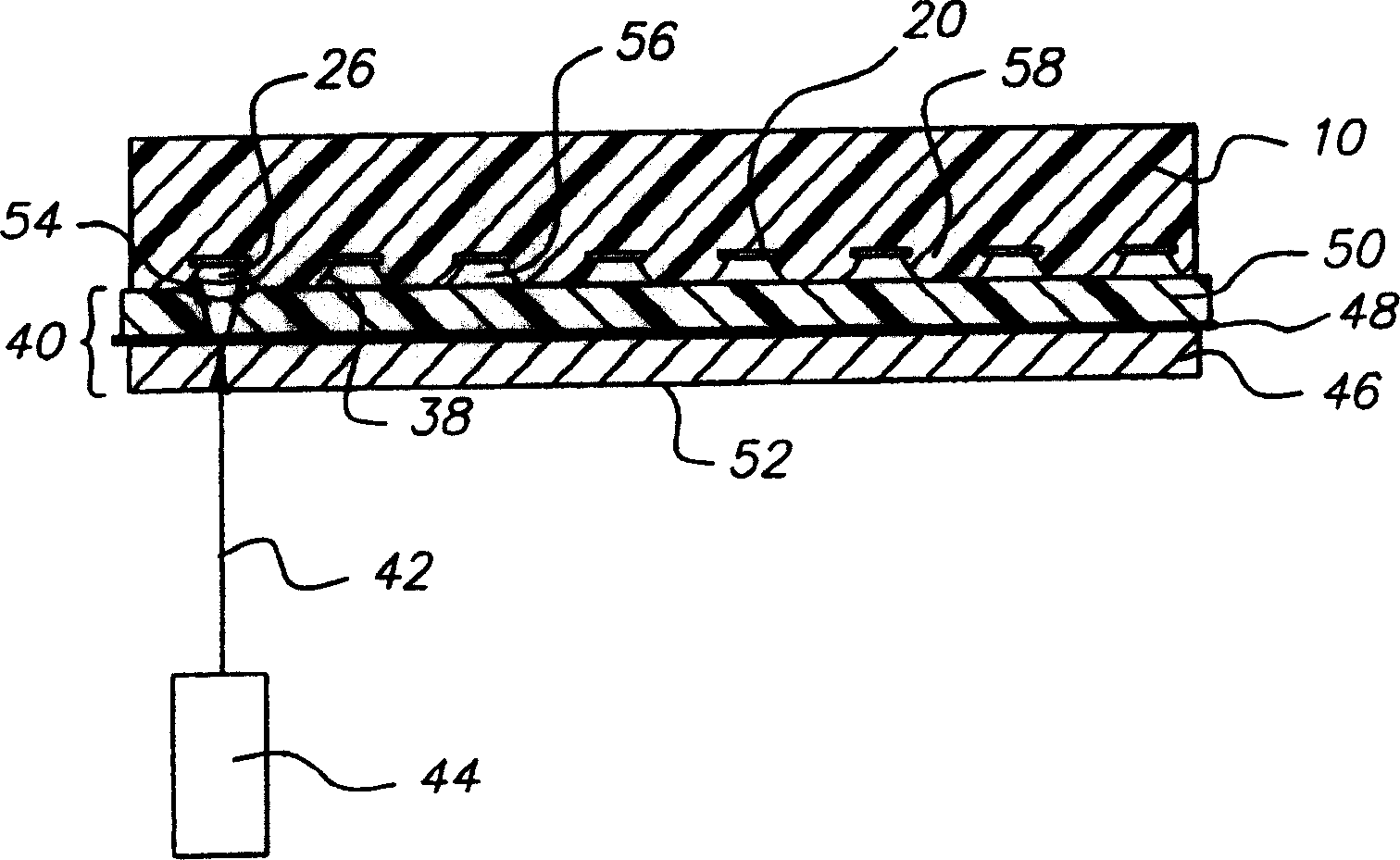

[0140] 5. Prepare a donor substrate by vacuum coating 40 nm of chr...

Embodiment 2

[0149] Embodiment 2 (comparative example)

[0150] OLED devices were fabricated using the method described in Example 1, except for step 11 (depositing an electron transport layer) as follows:

[0151] 11. A 35 nm electron transport layer of tris(8-quinolinate)aluminum(III) (ALQ) was vacuum deposited on the substrate with a coating station including a heated boat source.

[0152] result

[0153] Example

[0154] The device without doped low work function metal organic layer (Example 2) has significantly shorter half-life and higher voltage than the device with doped low work function metal organic layer (Example 1). Adding a lithium dopant to the electron transport layer increases the half-life by more than 2 times (Example 2 compared to Example 1), thus improving the stability of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com