Ceramic fiberboard and manufacturing technique

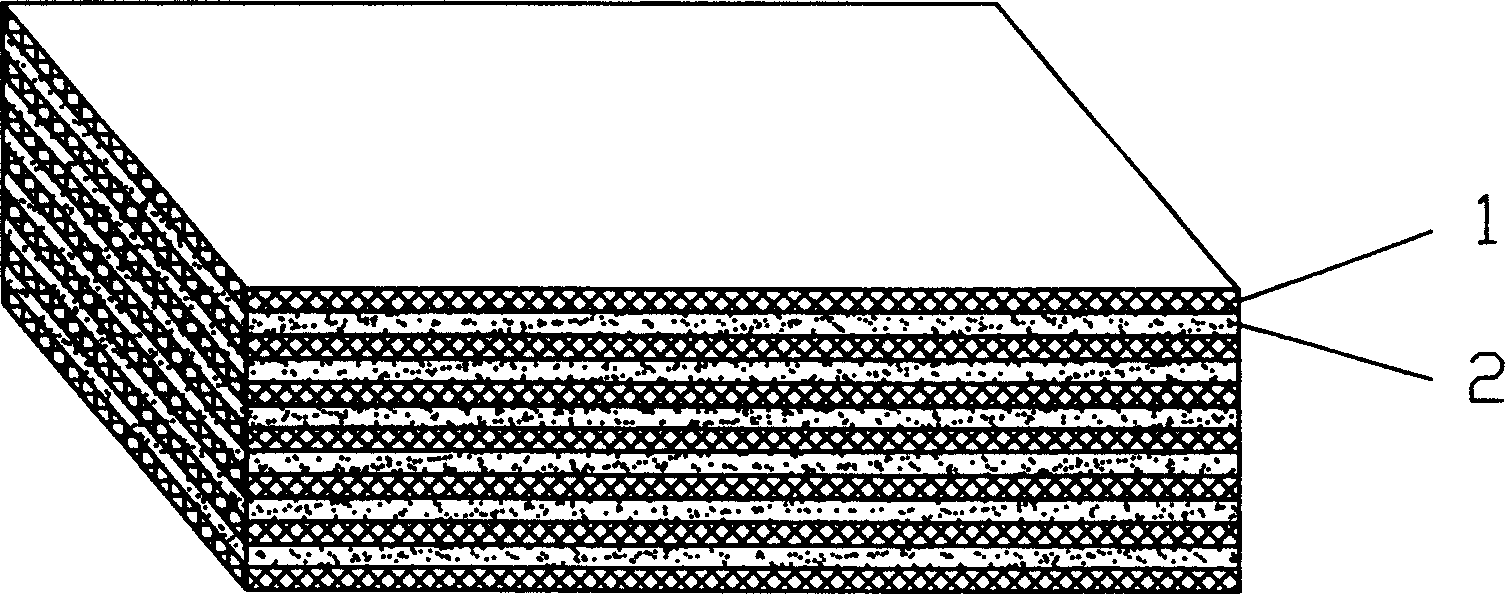

A ceramic fiberboard, production process technology, applied in fiberboard, textiles and papermaking, papermaking, etc., can solve the problems of low density, impact resistance, poor abrasion resistance, poor product strength, etc., to achieve high density and impact resistance Strong, good abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: (semi-continuous production method)

[0023] 1) Amorphous ceramic fibers with a diameter of 2-3 μm and a length of 20-80 mm are selected, and a ceramic fiber paper with a thickness of 0.4 mm and a width of 600 mm is produced by a wet continuous molding process.

[0024] 2) Cut the rolled ceramic fiber paper into a size and shape of 500mm×500mm for later use.

[0025] Acrylate emulsion 1000ml, polyacrylamide (molecular weight: 5 million) 3% aqueous solution 200ml, high alumina cement (CA-50) 1kg, kaolin 500g, talcum powder (325 mesh) 100g, wollastonite (400 mesh) 200g Stir vigorously and mix evenly for 4 to 5 minutes to form a paste-like binder and filler mixture for later use.

[0026] To produce a ceramic fiber board with a thickness of about 3.2mm: first spread a piece of ceramic fiber paper with a thickness of 0.4mm and 500mm×500mm, and evenly brush a layer of the above-mentioned paste binder material (150ml, thickness about 1.3mm), and cover the secon...

Embodiment 2

[0030] Embodiment 2: (continuous production method)

[0031] The specific operation process is as follows:

[0032] 1) Using amorphous ceramic fibers with a diameter of 2-3 μm and a length of 20-80 mm, a ceramic fiber paper with a thickness of 0.4 mm and a width of 600 mm is produced by a wet continuous molding process.

[0033] 2) Spray an acrylate emulsion adhesive with a solid content of 2-3% on the wet paper, and suck off part of the adhesive through a negative pressure of 0.01-0.02 MPa; at a distance of 30-50 cm from the applied adhesive, A linear feeder is used to evenly apply the powdery filler mixture (500g of high alumina cement, 300g of alumina, 200g of pyrophyllite powder, 100g of mica powder, and 150g of clay), and the filler applied per square meter is controlled between 70-150g. The filled ceramic fiber paper enters the drying oven.

[0034] 3) The temperature of the drying oven is controlled at 40-60°C, and the drying time is 3-5 minutes. At this time, the ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com