Method for preparing nitrogen doped titania visible light catalyzer

A technology of titanium dioxide and visible light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of catalyst particle aggregation, loss of specific surface area, and impact on visible light catalytic efficiency, and achieve heat treatment temperature reduction, The effect of improving doping efficiency and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

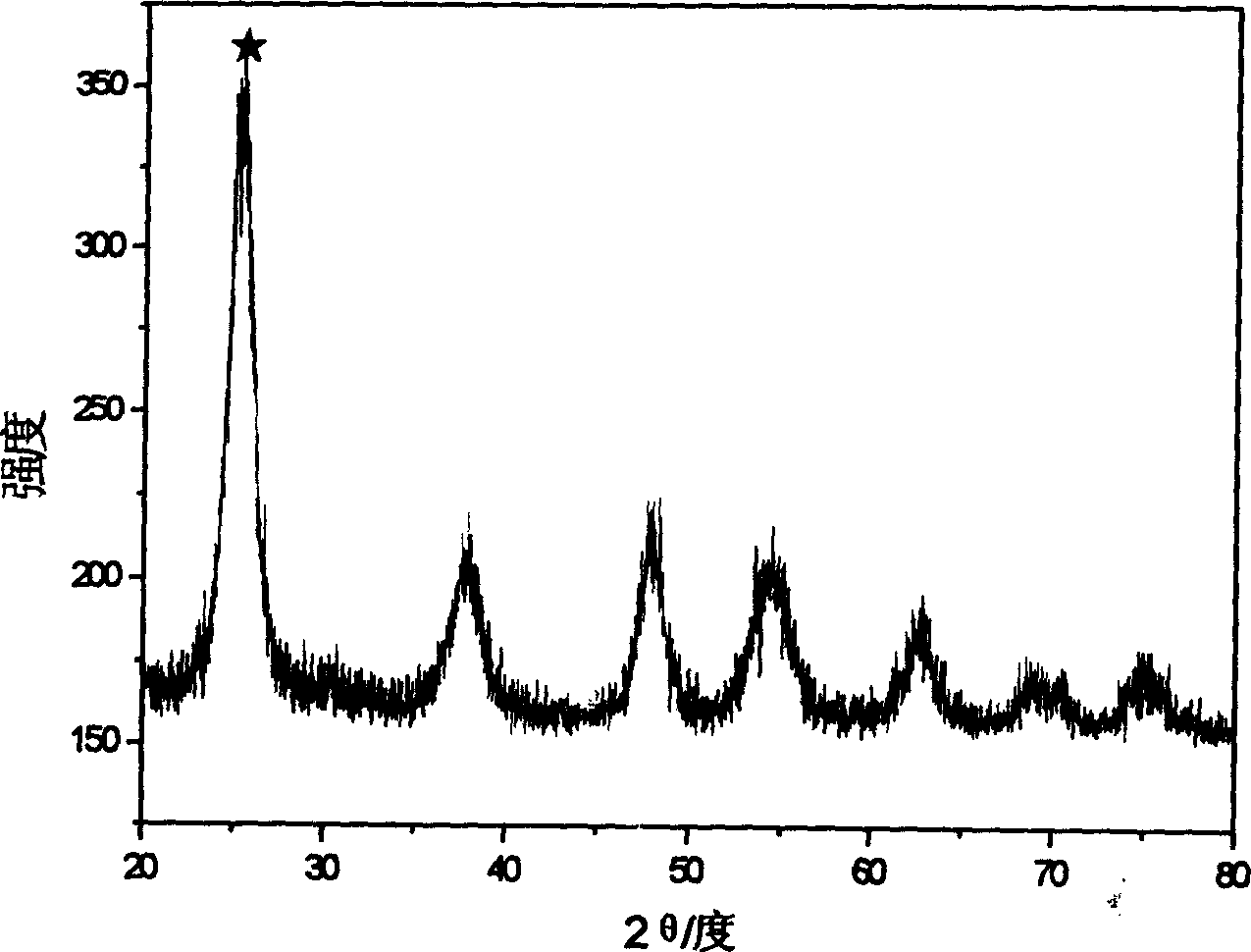

[0026] Nitrogen-doped titania catalyst 1# was prepared by two-step synthesis of sol-gel method under ultraviolet light irradiation:

[0027] The ratio of raw materials (percentage by weight, total weight is 50 grams) of synthetic titanium sol:

[0028] Isopropyl titanate (analytical pure): 2%

[0029] Absolute ethanol (analytical pure): 95%

[0030] Concentrated hydrochloric acid (36.5%): 2%

[0031] Ammonium chloride (analytical pure): 1%

[0032] Light intensity: 20mV / cm 2

[0033] Lighting time: 15 hours

[0034] Put isopropyl titanate, absolute ethanol, and concentrated hydrochloric acid in the reaction bottle according to the above ratio, stir at a temperature of 15°C and react for 15 hours under the irradiation of a 500W high-pressure mercury lamp; then add aqueous ammonium chloride solution to the reaction solution , continue to react for 2 hours to obtain titanium sol. The solvent was evaporated to obtain a gel, and the gel was dried in an air atmosphere at 100°...

Embodiment 2

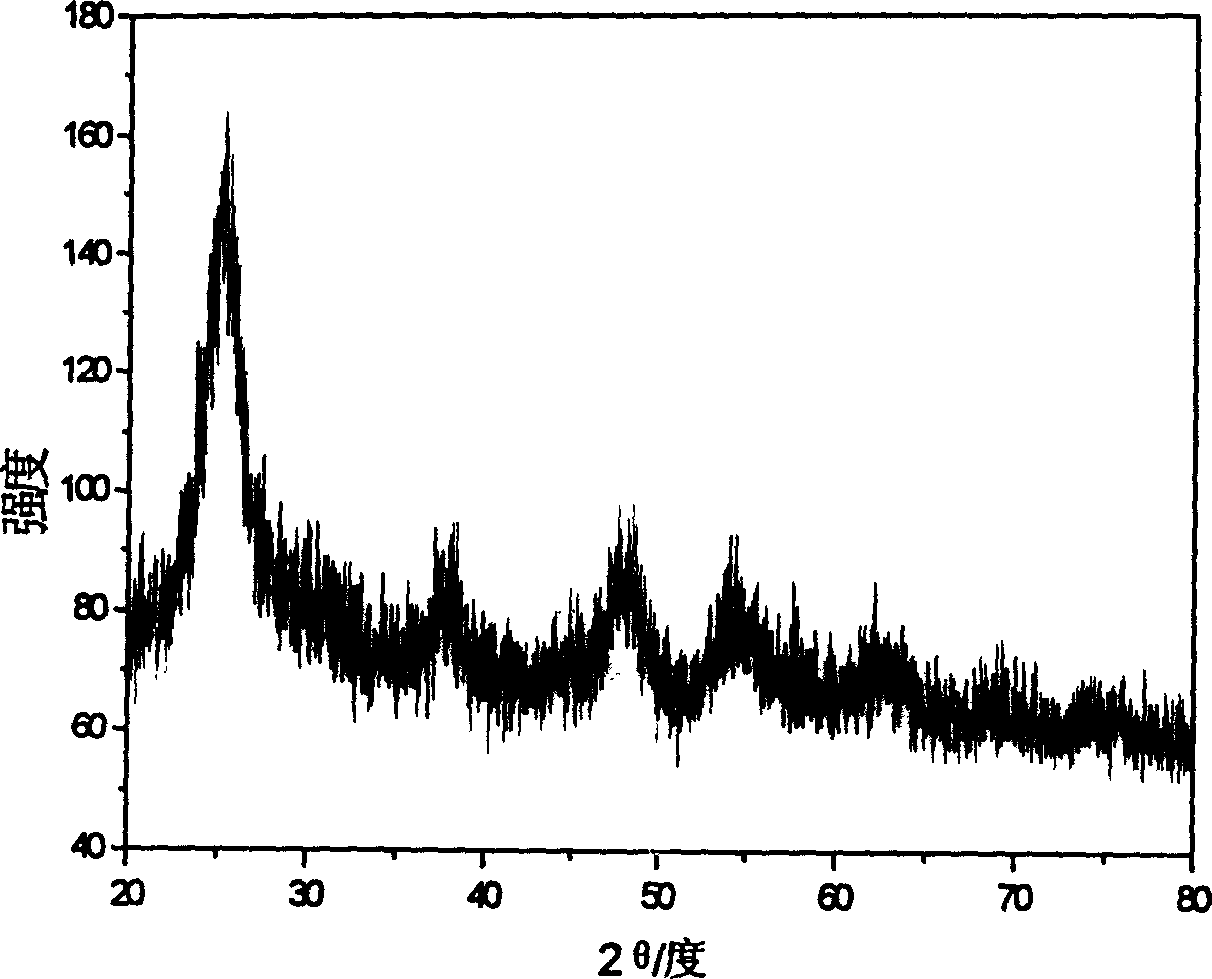

[0048] Preparation of nitrogen-doped titania catalyst 3# by sol-gel method under ultraviolet radiation:

[0049] The ratio of raw materials (percentage by weight, total weight is 50 grams) of synthetic titanium sol:

[0050] Isopropyl titanate (analytical pure): 2%

[0051] Absolute ethanol (analytical pure): 93%

[0052] Concentrated hydrochloric acid (36.5%): 1%

[0053] Ammonium chloride (analytical pure): 4%

[0054] Light intensity: 5mV / cm 2

[0055] Lighting time: 20 hours

[0056] Put isopropyl titanate, absolute ethanol, and concentrated hydrochloric acid in the reaction bottle according to the above ratio, and react at 25°C for 20 hours under the irradiation of a 300W medium-pressure mercury lamp; then add aqueous ammonium chloride solution to the reaction solution, The reaction was continued for 3 hours to obtain titanium sol. The solvent was evaporated to obtain a gel, and the gel was dried in an air atmosphere at 80° C. for 2 hours to obtain the target produ...

Embodiment 3

[0060] Research on visible light catalytic activity of nitrogen-doped titanium dioxide samples 1# and 3#:

[0061] A certain amount of 1#, 3# powder samples are placed in the acid pink aqueous solution of organic dye molecules, under the irradiation of 450nm visible monochromatic light, the acid pink aqueous solution gradually fades, and the organic dye molecules are degraded, see Figure 5 ; Similarly, in the degradation of other organic dye molecules with visible light, such as rhodamine B, eosin, phycoerythrin, eosin, etc., 1#, 3# samples all showed significant visible light catalytic activity, see Image 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com