Paraquat waste water containing cyanogen treating method

A treatment method and technology for cyanide wastewater, which are applied in the directions of oxidized water/sewage treatment, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high treatment cost, difficulty in treatment, and increase of salt content in wastewater, and reach the treatment cost. Low cost, simple process and small equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

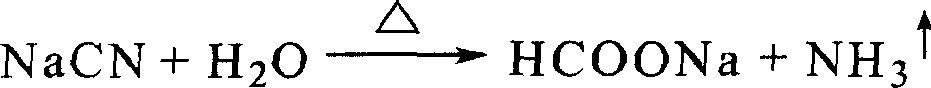

Method used

Image

Examples

Embodiment 1

[0023] In a 500 milliliter autoclave equipped with a thermometer, agitator, gas mass flow meter, and tail gas absorption system, add 300 grams of paraquat cyanide-containing wastewater stock solution (CN - 6000mg / l, COD 30,000mg / l), then drop into catalyst 10 grams, described catalyzer is carrier with activated carbon, and then attaches metal composite element, and described metal composite element is one of platinum, cerium, cobalt three kinds of elements Specifically, granular activated carbon is used as a catalyst, and the above-mentioned metal salt solution is coated on the activated carbon by impregnation method, and then roasted, and then the kettle is covered, stirred and heated to 130 °C, and opened. Air is introduced into the air valve to make the pressure reach 1.3Mpa, then the tail gas valve is opened to discharge a small amount of gas, and the air inlet valve is adjusted to keep the pressure in the kettle at 1.3Mpa. In this way, keep a constant temperature of 130°C...

Embodiment 2-6

[0025] The operation method is the same as that in Example 1, and the catalyst used in each batch is the same as in the previous example, and a new catalyst is added until the weight of the catalyst is 10 grams. Result is identical with embodiment 1, sees following table 1:

[0026] batch number

Embodiment 7

[0028] The operation method is the same as in Example 1, but 150 grams of waste water stock solution is added, and 150 grams of water is added; the reaction time is 18 hours. The result was the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com