Method for preparing high quality ZnO single crystal thin film on (La, Sr) (Al, Ta) O3

A single-crystal thin-film, high-quality technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to solve problems such as large film strain, poor crystal quality and optoelectronic properties, and lattice mismatch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the preparation method of the present invention and the accompanying drawings.

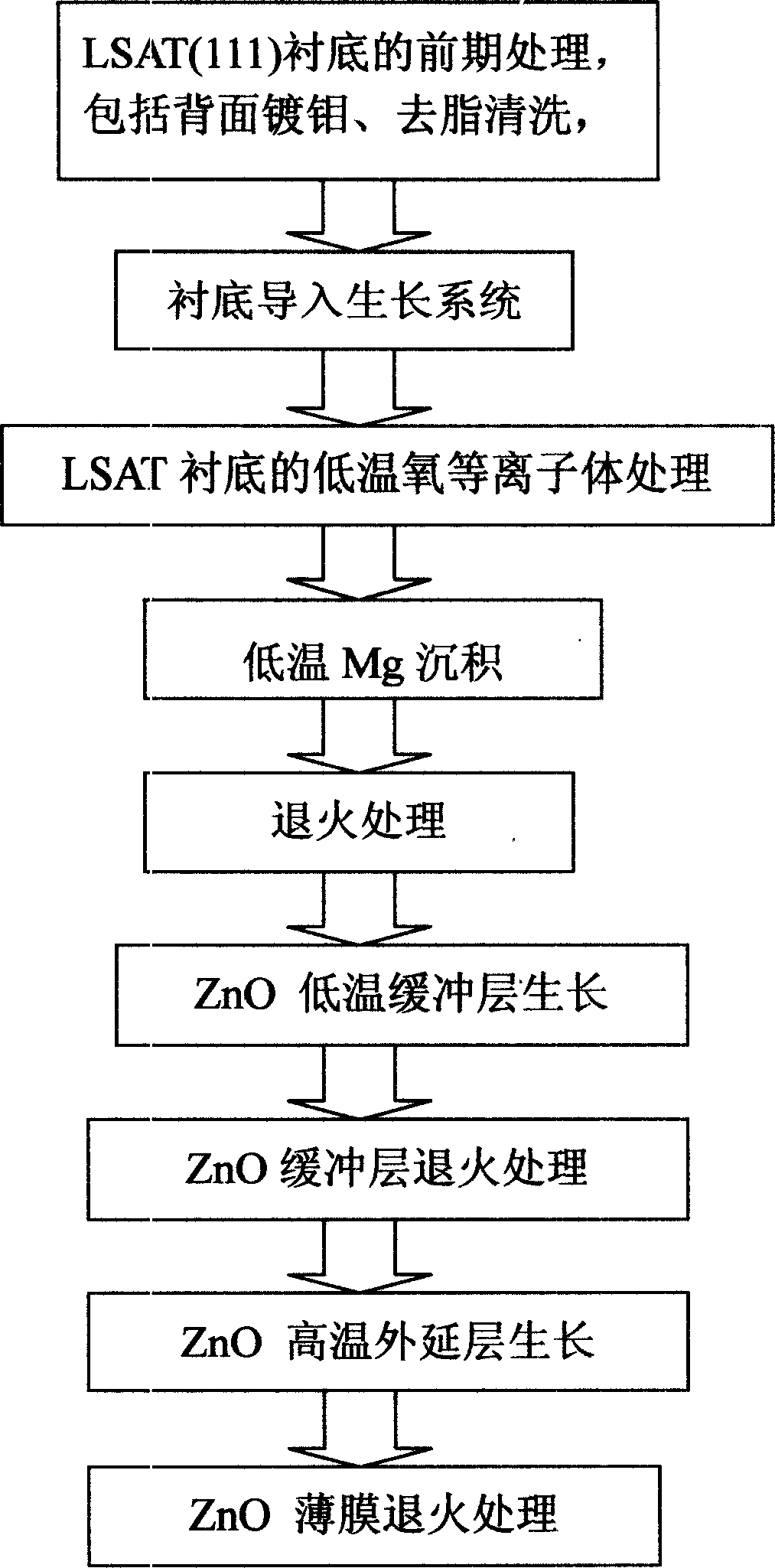

[0020] Such as figure 1 Shown process flow diagram of the present invention, the concrete steps of preparing high-quality O polarity ZnO single crystal thin film on LSAT (111) substrate are as follows:

[0021] 1) Plating molybdenum on the back of the LSAT (111) substrate, degreasing and cleaning, and then introducing the substrate into the molecular beam epitaxy growth system;

[0022] 2) Perform radio frequency oxygen plasma treatment at a low temperature of 180° C. for 30 minutes, the radio frequency power is 350 W, and the oxygen flow rate is 2.5 sccm to obtain an LSAT (111) substrate with an O-terminated surface;

[0023] 3) At air pressure -7 When the Pa and the substrate temperature are 180°C to deposit metallic magnesium, the equivalent vapor pressure of the magnesium beam is 1×10 -5 Pa, control the deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com