New lactic acid bacteria, its bacteriocin, and food processing method using said bacteria

A processing method and technology of lactic acid bacteria, applied in bacteria, food preservation, food preparation, etc., can solve the problem of unnamed bacteriocin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

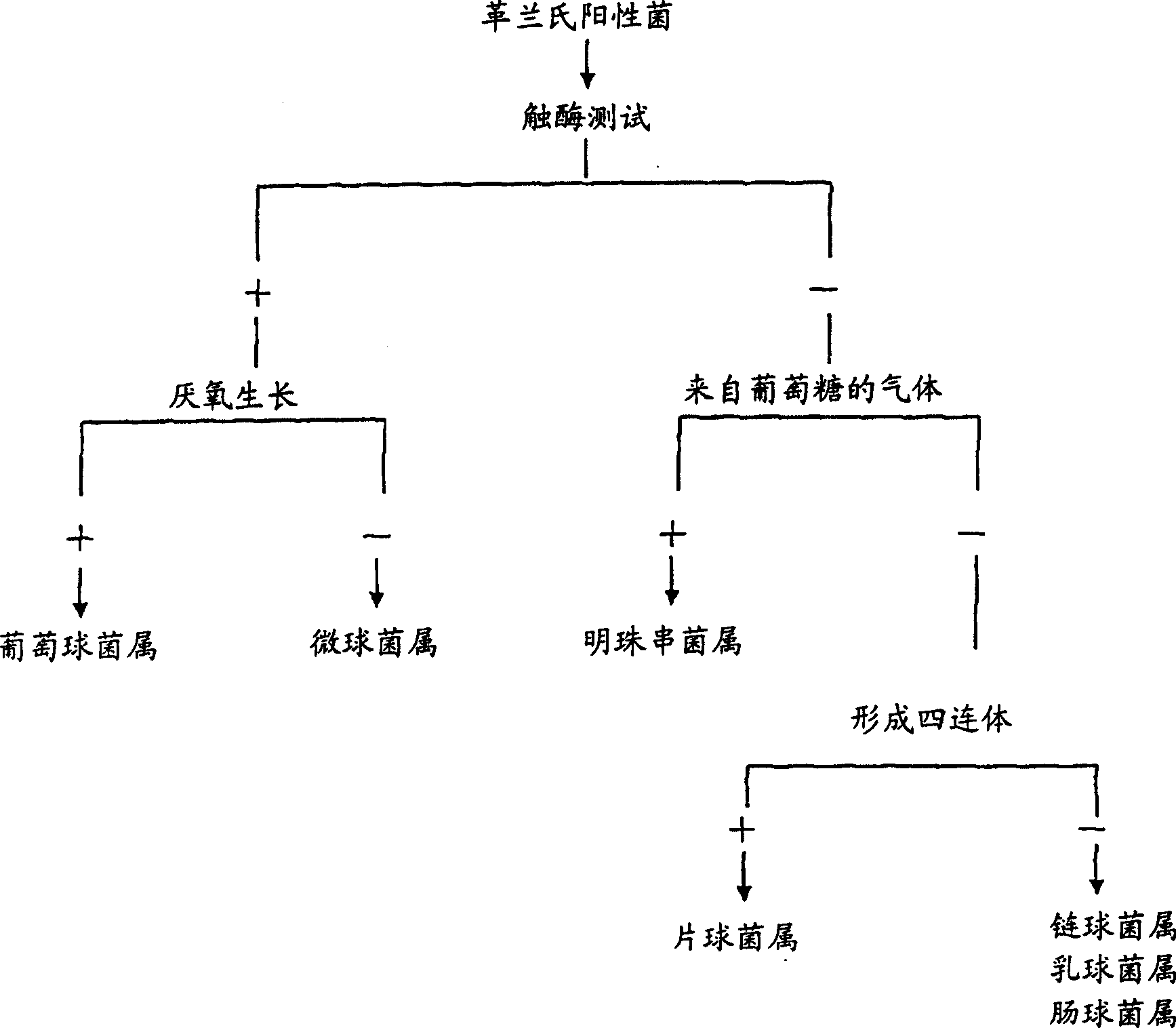

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0179]Example 2 Fish processing method using Lactobacillus acidophilus CCRC10069, Lactococcus lactis subspecies CCRC 12315, Lactobacillus helveticus CCRC 14092, Pediococcus pentosaceae YJL BCRC910210 and Pediococcus pentosaceae YJS BCRC910211

[0180] Frozen mackerel is thawed under running water at room temperature, and the internal organs and heads are removed, and the meat is harvested with a meat slicer. Dissolve it in homogeneous salt solution with equal volume of 2% NaCl solution, and then make a three-fold dilution of the fish matrix. After being sterilized at 100°C for 20 minutes, cool to 40°C, and finally add 4% sucrose, 1% glucose and lactic acid bacteria, mix evenly with a sterilized glass rod, and ferment at 37°C for 48 hours. The concentration of lactic acid bacteria inoculated in this matrix is about 10 5 CFU / g. The items detected in the experiment include pH value, the number of lactic acid bacteria and the number of aerobic bacteria. In addition, changes ...

Embodiment 3

[0235] Example 3 Fish cheese and yoghurt processing methods utilizing Lactobacillus acidophilus CCRC10069, Lactococcus lactis subspecies CCRC 12315, Lactobacillus helveticus CCRC 14092, Pediococcus pentosaceae YJL BCRC910210 and Pediococcus pentosaceae YJSBCRC910211

[0236] Frozen silver carp slurry was thawed at 5°C overnight, then homogenized with an equal volume of 1.0% NaCl solution, sterilized at 100-115°C for 15 minutes, then cooled to 30°C, and added with 4% sucrose and lactic acid bacteria to sterilize the glass stick Mix evenly and ferment at 37°C for 24 hours. The concentration of lactic acid bacteria inoculated in this matrix is about 10 5 CFU / g. Finally, after adding an appropriate amount of sesame or peanut powder, sterilize at 100-115°C for 15 minutes, and shape (such as image 3 and 4 shown) were square and were subjected to sensory evaluation after moderate drying.

[0237] Results: After 24 hours of fermentation at 37°C, the pH values of the five lact...

Embodiment 4

[0239] Bean Processing Method Utilizing Pediococcus Pentosaceae YJL and Pediococcus Pentosaceae YJS

[0240] Add water to the soaked soybeans, homogenize, filter, heat and sterilize at 100-115°C for 20 minutes, then cool to 30°C, adjust the moisture content of the matrix to 60%, and finally add 4% sucrose, 1% glucose and lactic acid bacteria to sterilize the glass. Mix evenly off the sticks and ferment at 37°C for 24 hours. The concentration of lactic acid bacteria inoculated in this matrix is about 10 5 CFU / g. And detect changes in pH value, lactic acid bacteria count, aerobic bacteria count, main microbial flora ~ Pseudomonas, Staphylococcus and Enterobacteriaceae and other flora. Finally, add an appropriate amount of strawberries and sugar to make a pudding (such as Figure 5 ), and make a sensory evaluation.

[0241] Results: After 24 hours of fermentation at 37°C, the pH value of lactic acid bacteria fermented products decreased from 6.0-6.2 to 4.7-4.9, and the pH v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com