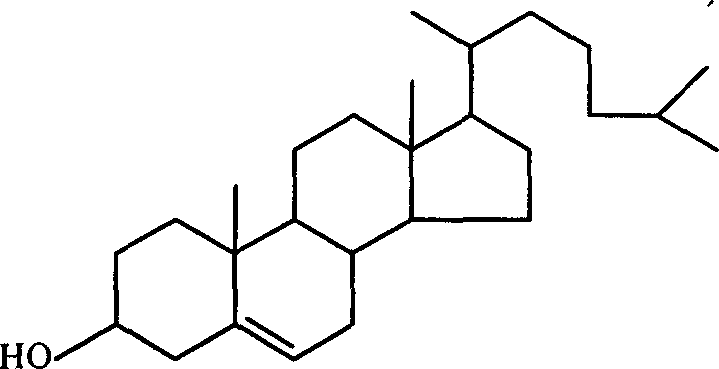

Method for separating and extracting cholesterol from lanolin

A lanolin and cholesterol technology, applied in the direction of steroids, organic chemistry, etc., can solve the problems of large investment and high equipment requirements, and achieve the effects of wide adaptability, less damage and lower consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 200 grams of refined lanolin, 30 grams of solid sodium hydroxide (industrial grade) and 500 ml of 60% methanol (industrial grade) into a 1000 ml three-necked flask equipped with a thermometer, condenser and agitator. After the temperature was raised to 60°C, the stirring was started, and the reaction was stopped after stirring for 2.0 hours at this temperature. The reaction device was changed to a distillation device to distill most of the solvent. The residue was dried at 105°C for 2 hours, and 220 g of light brown solid was obtained after cooling. The saponified product was extracted with 1800 ml of ethyl acetate at room temperature in three batches of lanolin (including cholesterol), and filtered to obtain 1700 ml of filtrate. After evaporating the ethyl acetate in the filtrate, the residue was dissolved with 1400 ml of n-hexane. 500 ml of 70% methanol was added to the n-hexane solution, stirred at room temperature for 30 minutes, and then allowed to stand for separa...

Embodiment 2

[0031]200 g of crude lanolin and 200 ml of 0.2% OP-10 aqueous solution were added to a 1000 ml three-necked flask equipped with a thermometer, condenser and agitator. After stirring for 2 hours at 60°C, the mixture was allowed to stand and separate into layers. After the water layer was separated, 50 grams of solid potassium hydroxide (industrial grade) and 500 ml of 80% ethanol (industrial grade) were added. After the temperature was raised to 60°C, the stirring was started, and the stirring was performed at this temperature for 3.0 hours. Afterwards, the saponified product was treated according to the method of Example 1 to obtain 210 g of brown saponified product. At 40°C, 1800 ml of petroleum ether with a boiling range of 60~90°C was used to extract lanolin from the saponified product three times, and 1700 ml of filtrate was obtained by filtration. The filtrate was washed 3 times with 1600 ml of 80% ethanol at room temperature. After the ethanol was separated, the petroleum et...

Embodiment 3

[0033] The pretreatment of crude lanolin is the same as in Example 2, wherein 0.2% OP-10 aqueous solution is changed to 0.2% plain water solution, and the saponification reaction and post-treatment are the same as in Example 1. At 50℃, 900 ml of dichloroethane is divided into three extractions. Medium wool alcohol. At room temperature, the extract was washed with 900 ml of 80% methanol three times. After the methanol layer was separated, the dichloroethane was evaporated to obtain 46 grams of a dark paste. Using industrial ethanol, according to the crystallization operation in Example 1, 8 grams of white cholesterol was finally obtained, the purity of cholesterol was 90%, and the yield was 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com