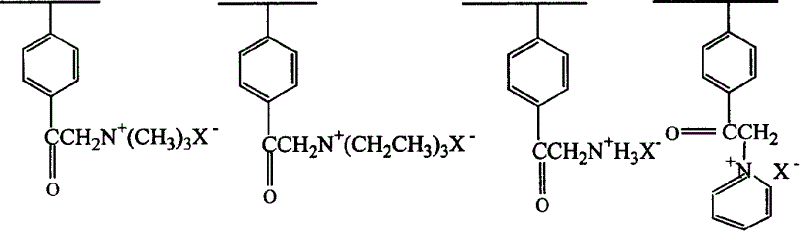

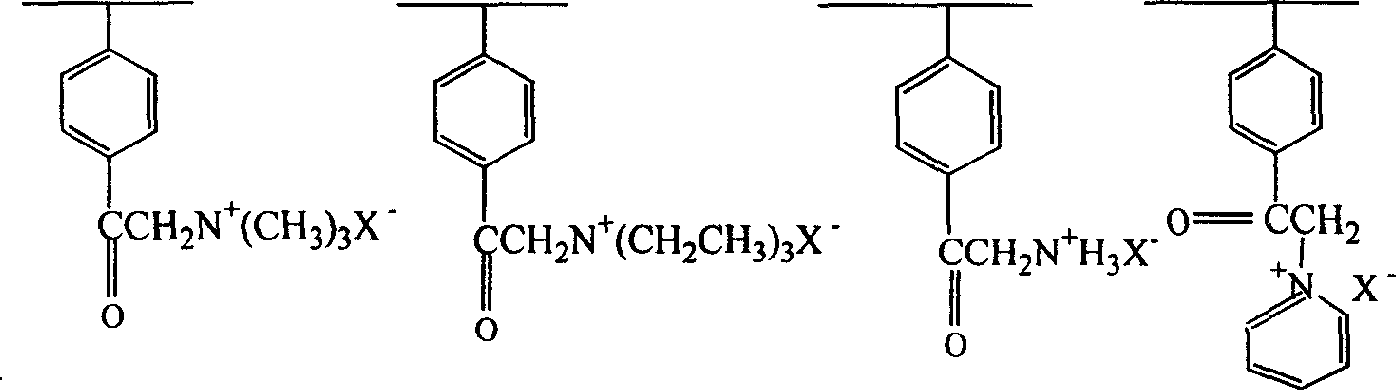

Quaternary ammonium type anion exchange agent and its preparation method

An anion exchanger, quaternary ammonium type technology, applied in the field of functional polymers, can solve the problem of low exchange capacity of quaternary ammonium groups, and achieve the effects of improving multi-substitution and secondary cross-linking, high conversion rate and reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 1g of polystyrene (cross-linking degree: 7% DVB, particle size: 8μm) into a three-neck reaction flask, add anhydrous dichloromethane to swell, stir to make it evenly dispersed, add 0.8ml of chloroacetyl chloride dropwise, and blow in nitrogen , Add 1.3g of aluminum trichloride under stirring, and react at room temperature and pressure for 4.5h. That is, chloroacetylated polystyrene with a supported amount of 4.1 meq / g was obtained.

[0025] Take 1g of the above resin in a round bottom beaker, add 10ml of tetrahydrofuran, swell for 12h, add trimethylamine, stir to disperse evenly, and react at 70°C under normal pressure for 3h. That is, a quaternized resin with a loading capacity of 3.3 meq / g was obtained.

Embodiment 2

[0027] Take 1g of polystyrene (cross-linking degree: 7% DVB, particle size: 200μm) into a three-necked reaction flask, add anhydrous dichloromethane to swell, stir to make it evenly dispersed, add 0.16ml of chloroacetyl chloride dropwise, and blow in nitrogen , add 0.26g of aluminum trichloride under stirring, and react at normal temperature and pressure for 1h. That is, chloroacetylated polystyrene with a loading amount of 1.5 meq / g was obtained.

[0028] Take 1g of the above resin in a round-bottomed beaker, add 5ml of tetrahydrofuran, swell for 12h, add trimethylamine, stir to disperse evenly, and react at 70°C under normal pressure for 3h. That is, a quaternized resin with a loading capacity of 1.4meq / g was obtained.

Embodiment 3

[0030] Take 10g of polystyrene (cross-linking degree: 7% DVB, particle size: 200μm) into a three-necked reaction flask, add anhydrous dichloromethane to swell, stir to disperse evenly, add 0.3ml of bromoacetyl bromide dropwise, and blow in nitrogen , add 1.4g of zinc chloride under stirring, and react at room temperature and pressure for 0.5h. That is, bromoacetylated polystyrene with a loading amount of 0.34 meq / g was obtained.

[0031] Take 1g of the above resin in a round bottom beaker, add 5ml of ethanol, swell for 12h, add trimethylamine, stir to disperse evenly, and react at 70°C under normal pressure for 3h. That is, a quaternized resin with a loading capacity of 0.33meq / g was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com