Internal fixer composite material with living things absorption and preparation

A composite material and fixing device technology, applied in the field of medical device materials and preparation, to achieve the effect of simple processing and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

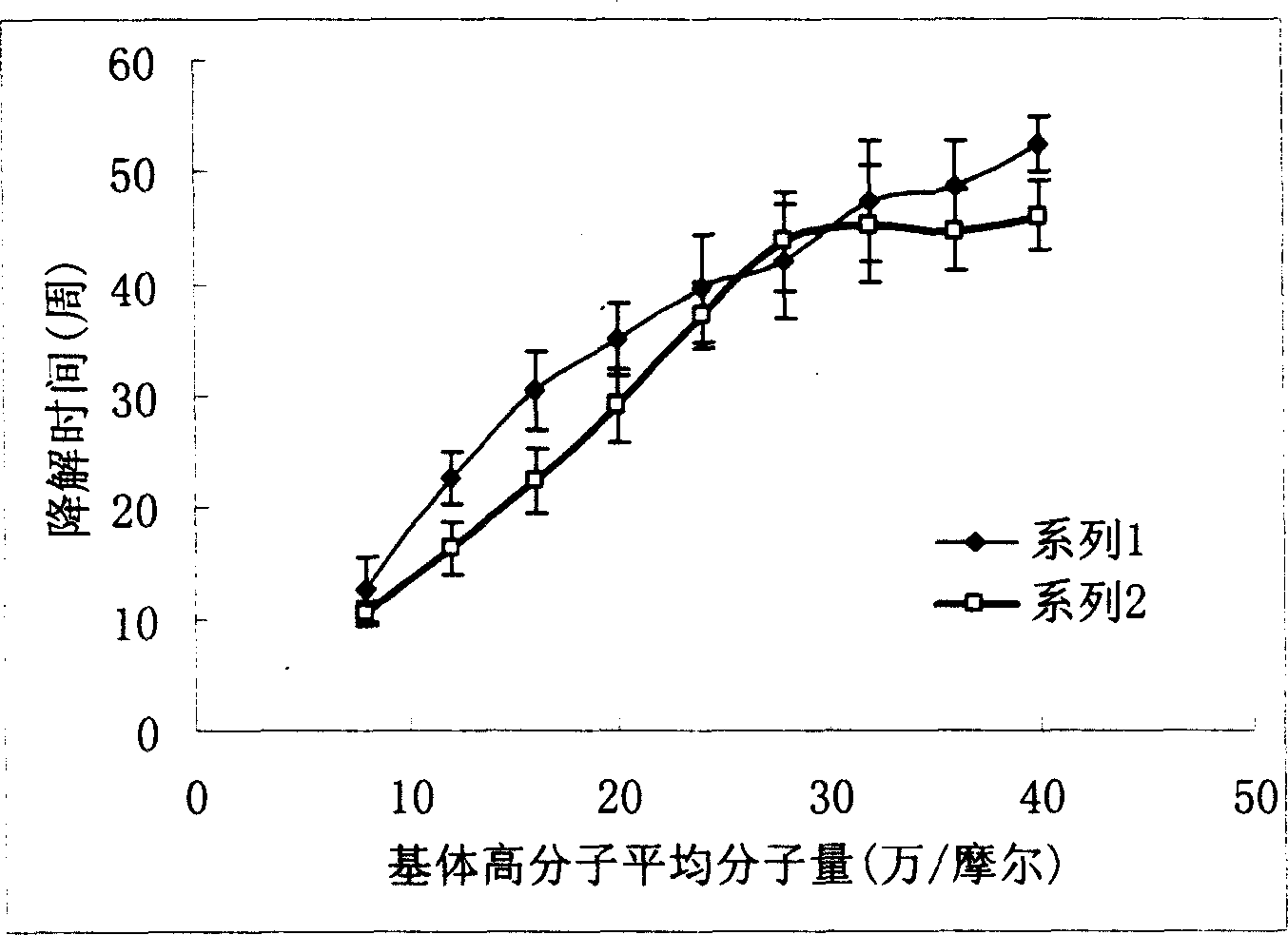

Image

Examples

Embodiment 1

[0048] The poly-L-lactic acid with a viscosity average molecular weight of 160,000 and the polyglycolic acid with a viscosity average molecular weight of 300,000 are respectively pulverized into powders with a particle size of less than 200 microns; tricalcium phosphate and hydroxyapatite powders with a particle size of less than 50 microns are selected. Mixing poly-L-lactic acid, polyglycolic acid, tricalcium phosphate and hydroxyapatite in proportion, the weight percentage is 83%, 3%, 4%, 10%, and then adding pyrolytic carbon fiber with a volume percentage of 0.5% , mixed evenly, and then molded into rods and plates at 145 ° C and a pressure of 15 MPa, and processed into pins, screws, nails, and plates for orthopedic internal fixation devices by ordinary machining methods, and then filled with 5% polystyrene After soaking in poly-l-lysine aqueous solution for 12 hours, air-dry in airflow. The bending strength is 180MPa, and the shearing strength is 90MPa. After soaking in ph...

Embodiment 2

[0050] Grind poly-L-lactic acid with a viscosity-average molecular weight of 280,000 and polyglycolic acid with a viscosity average molecular weight of 280,000 and 120,000, respectively, into powders with a particle size of less than 200 microns; select tricalcium phosphate and hydroxyapatite powders with a particle size of less than 50 microns, and use silane coupling agent to treat the surface. Make acryloyloxy KH-570 silane coupling agent into 100ml of 1% water-alcohol mixture, add 50g of tricalcium phosphate and hydroxyapatite mixed powder, heat and stir for 2h, let stand for 4h, filter, Wash repeatedly with distilled water, dry, and pass through a 180-mesh sieve. Mix poly-L-lactic acid, polyglycolic acid, tricalcium phosphate and hydroxyapatite in proportion, and the weight percentage is 80%, 6%, 4%, 10%, mix well, and then extrude into rods at 205°C Materials and plates, which are processed into pins, screws, nails, plates orthopedic internal fixation devices by common ...

Embodiment 3

[0052] 350,000 poly-L-lactic acid and 200,000 polyglycolic acid with a viscosity-average molecular weight of 350,000 are pulverized into powders less than 200 microns in particle size; Methods Use silane coupling agent for surface treatment. Add pyrolytic carbon fiber to boiling K 2 MnO 4 and H 2 SO 4 After cleaning in the mixed solution, rinse repeatedly with distilled water, dry at 80°C for 2 hours, then treat the cleaned pyrolytic carbon fiber in a 1% water-alcohol mixture made of H-570 silane coupling agent, and rinse repeatedly with distilled water , then dry. Mix poly-L-lactic acid, polyglycolic acid, tricalcium phosphate and hydroxyapatite in proportion, the weight percentage is 75%, 5%, 6%, 14%, and then add pyrolytic carbon fiber with a volume percentage of 0.5% , mixed evenly, and then molded into rods and plates at 150 ° C under a pressure of 15 MPa, and processed into pins, screws, nails, and plates for orthopedic internal fixation devices by ordinary machinin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com