Asphalt aqueous emulsion and method for preparation

A water emulsion and bitumen technology, which is used in water treatment and refining, tar bitumen/petroleum bitumen/natural bitumen processing, petroleum industry, etc. problem, to achieve the effect of easy control, uniform dispersion and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 620 grams of butane solvent deoiled asphalt raw material (its properties are shown in Table 1) and 88 grams of heavy deasphalted oil were blended into a mixture, and the temperature of the mixture was raised to 200°C. In 281.2 grams of water, add 4 grams of emulsifier sodium oleamide methoxybenzene sulfonate (molecular formula is C 25 h 40 NNaO 5 S, the brand is MA, produced by Shanghai Auxiliary Factory, the same below) and the mixture of sodium lignosulfonate (the brand is L-1, produced by Fushun Petrochemical Research Institute) (the weight ratio of the former to the latter is 3 : 1), 5 grams of additive NH 4 Cl (produced by Beijing No. 2 Chemical Plant) and 1.8 g of stabilizer polyvinyl alcohol (brand name 1788, produced by Beijing Organic Chemical Plant) were dissolved to obtain an aqueous solution, and the aqueous solution was heated to 75°C. The above mixture and aqueous solution were thoroughly mixed with a homogenizer (model M50, produced by Shanghai Qidong ...

Embodiment 2

[0060] 550 grams of pentane solvent deoiled asphalt raw material (its properties are shown in Table 1) and 150 grams of catalytic cracking oil slurry were blended into a mixture, and the temperature of the mixture was raised to 240°C. In 280.5 grams of water, add 15 grams of emulsifier C18 alkyl sodium sulfate (produced by Jinling Petrochemical Nanjing Alkyl Benzene Plant), 3 grams of auxiliary agent K 2 SO 4 (produced by Beijing No. 2 Chemical Factory) and 1.5 grams of stabilizer polyvinyl alcohol (the brand is 0486, produced by Beijing Organic Chemical Factory) were dissolved to obtain an aqueous solution, and the aqueous solution was heated to 80°C. The above mixture and aqueous solution were thoroughly mixed with a homogenizer to obtain an asphalt water emulsion product, the composition and properties of which are shown in Table 4.

[0061] The product has no precipitation within 7 days. Although it has been placed for more than half a year, precipitation or stratificatio...

Embodiment 3

[0063] 650 grams of propane solvent deoiled asphalt raw material (see Table 2 for its properties) was heated to 140°C. In 329 grams of water, add 15 grams of emulsifier C18 alkyl diethyl hydroxyethyl ammonium nitrate (the trade mark is SN, produced by Shanghai auxiliary agent factory), 2 grams of auxiliary agent Mg 2 SO 4 (produced by Beijing No. 2 Chemical Factory) and 4 grams of stabilizer cellulose (produced by Beijing Synthetic Detergent Factory) were dissolved to obtain an aqueous solution, and the aqueous solution was heated to 60° C. The above asphalt raw materials and aqueous solution were fully mixed with a colloid mill (model W4, produced by Wenzhou Colloid Mill Factory, the same below) to obtain an asphalt water emulsion product. The composition and properties of this product are shown in Table 4.

[0064] The product has no precipitation within 7 days. Although it has been placed for more than half a year, precipitation or stratification will gradually appear. How...

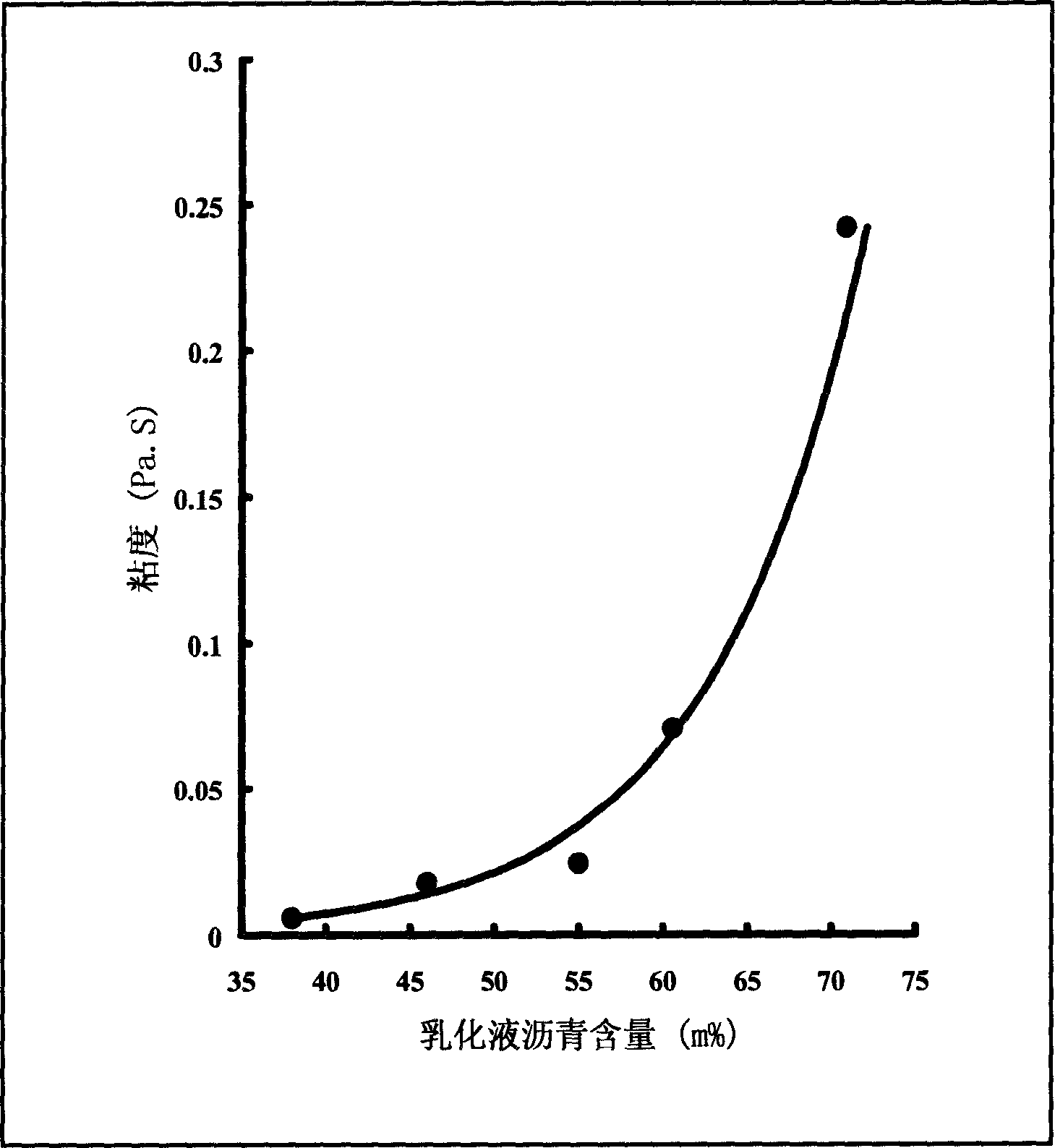

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com