Non preheating argon arc fusion welding method for thick red copper plate

A technology of argon arc welding and red copper, applied in the direction of arc welding equipment, welding medium, welding equipment, etc., can solve the problems of large changes in structure and performance, failure to form welds, high welding temperature, etc., to reduce the width and coarseness of grains degree, welding speed increase, the effect of low welding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

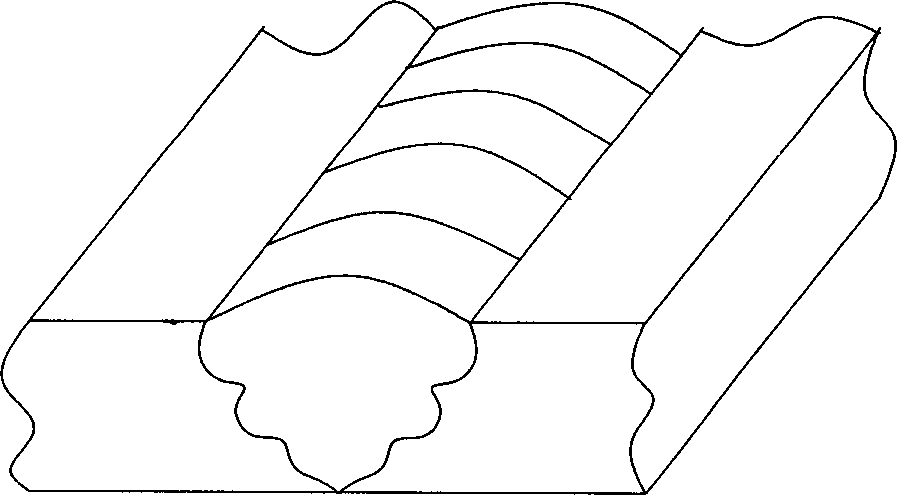

[0024] Specific embodiment one: In this embodiment, according to the following steps, non-preheating argon arc welding wire arc welding is carried out on thick plate red copper: a. Open a bevel on the red copper thick plate test piece, and place a ceramic gasket or a high temperature resistant material on it. Below the groove of the copper plate; b. Adjust the welding current, use the TIG arc to heat the groove of the base metal, and fill the alloy solder, so that the metal and the filler alloy at the groove where the copper plate is heated dissolve each other; c. Move forward along the groove Arc, repeat step b to realize the welding of the whole weld seam, see the welding section image 3 . In order to prevent the arc from staying in the groove for too long and excessive heat input, the difference between the heat-affected zone grains near the groove and the base metal grains will be too large, which will affect the performance of the overall welded joint. The welding speed ...

specific Embodiment approach 2

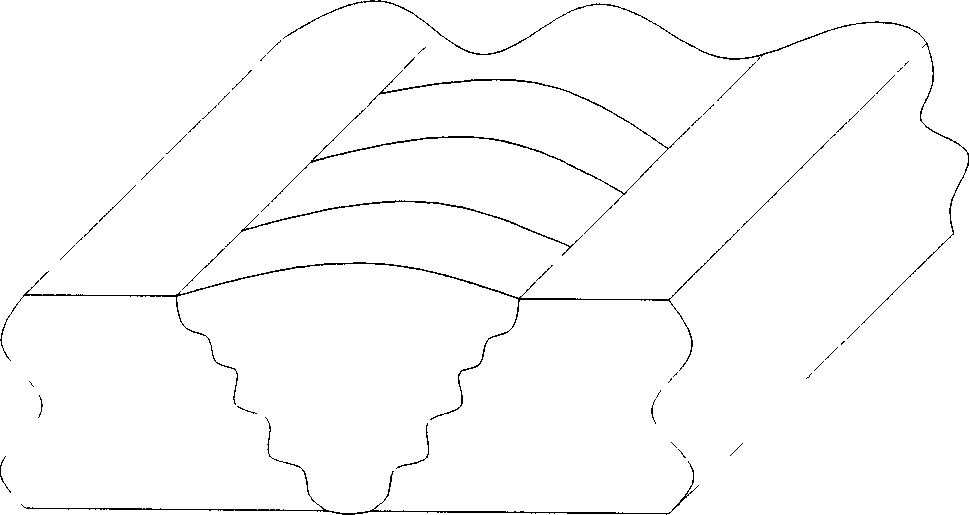

[0025] Specific embodiment two: This embodiment is achieved in this way: a. Open a V-shaped groove on the thick copper plate test piece or a groove suitable for the relative thickness of the plate, and place ceramic gaskets or high-temperature resistant materials on the groove of the copper plate The bottom of the base metal to prevent the loss of the mixture of the dissolved base metal and alloy solder; b. Adjust different welding currents according to the thickness of the base metal of the thick copper plate. The current is controlled between 100 and 250A, and the groove of the base metal is heated by TIG arc , fill the alloy welding wire without swinging the arc, the arc stays in the groove for 0.5~1s, and the local temperature reaches above 700°C, and the base metal begins to be dissolved when the filling solder alloy is observed with the naked eye; c. When the base metal is dissolved enough time (about 1-5mm, generally greater than or equal to the amount of melted base met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current intensity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com