Production method and device of nanmeter antimong trioxide

A technology of antimony trioxide and a production method, which is applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, can solve the problems of short gasification reaction time, difficult production and acquisition, fast falling speed, etc., and achieves simple process equipment, The effect of good product quality and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

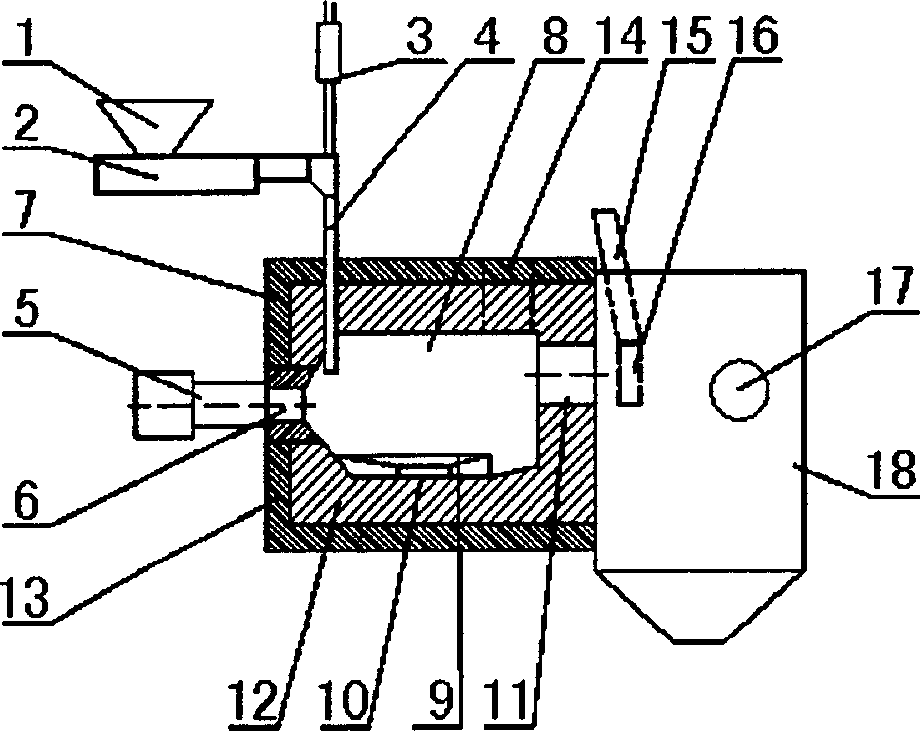

[0014] Embodiment 1: the production device of nano antimony trioxide is as attached figure 1 As shown, it includes plasma generator, feeding device, reactor and quenching settler. The characteristics are: the reactor is a horizontal reactor, the structure of the horizontal reactor includes a horizontal reaction chamber 8, the reaction chamber 8 is connected to the plasma generator 5 through the heat source inlet 6 in the horizontal direction at the end, and the heat source The inlet 6 can be made of high temperature resistant material or stainless steel water jacket, and the reaction chamber 8 is lined with high temperature refractory material 12 and thermal insulation material 13 . The working temperature of the inner wall of the reaction chamber 8 is 1400-1900°C. It is connected to the feeding device through the upper feed port, and connected to the quenching settler 18 through the tail discharge port 11 or 14. The lower part of the reaction chamber 8 is provided with a sec...

Embodiment 2

[0015] Example 2. Using high-grade antimony oxide ore powder with a particle size of no more than 0.5 mm as raw material, its chemical composition is Sb 70%, As 0.05%, Pb 0.08%, Se 0.003%, Fe 0.2%, and the balance is other impurities; DC arc is used Plasma generator, input power 120KW, the air plasma temperature generated is 5000-8000℃, and the air working gas volume is 18m 3 / h; the powder dosage per hour is 16kg; the first gasification time of the powder in the reactor is controlled above 0.3 seconds; the temperature of the reaction product at the outlet of the reactor is 1700-1900°C, and the cooling air volume is 950m 3 / h, cooling rate 9×10 5 °C / s. The finished product obtained has the following properties. Specific surface area: Using ST-03 specific surface meter, the result measured according to GB / T13390-1992 standard is 61.5 meters 2 / g; Particle size: Using H-700 70,000 times transmission electron microscope, the detection result particle size ranges from 10 to 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com