Stable alkali thiourea system and its selective immersion gold method

A selectivity and thiourea technology, applied in the direction of improving process efficiency, etc., can solve problems such as complex solution regeneration and purification process, insoluble gold, equipment corrosion, etc., and achieve the promotion of sustainable and coordinated development, non-toxic gold leaching, and operation requirements low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

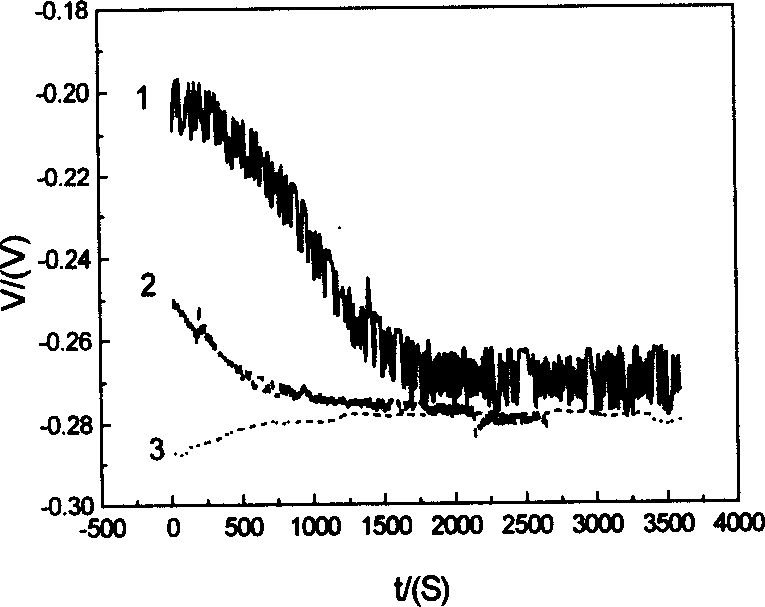

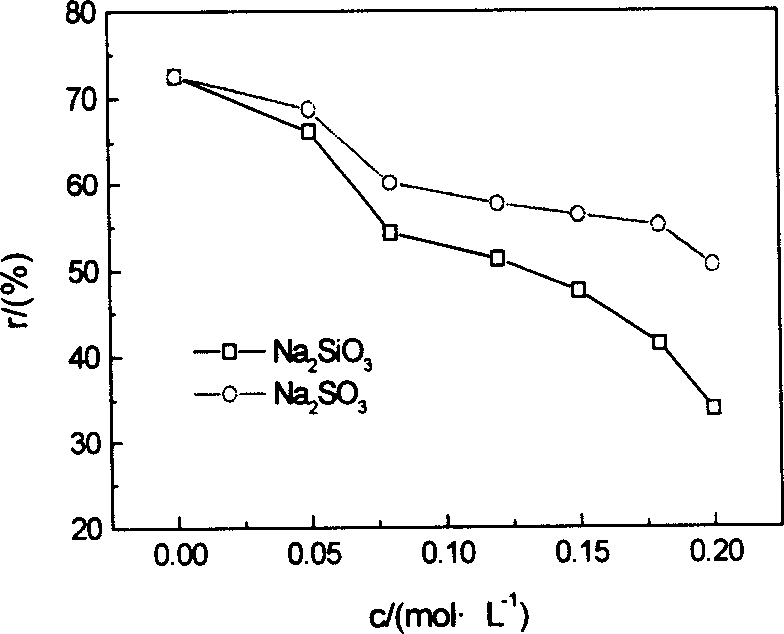

[0015] Embodiment 1: Alkaline thiourea system

[0016] at 0.1mol·L -1 Add 0.25mol·L to the thiourea solution -1 Stabilizer Na 2 SO 3 To form a thiourea system, add 0.2mol L -1 Stabilizer Na 2 SiO 3 Form another thiourea system, and adjust the pH value of the solution to be 12.5. When the temperature is 25°C, the gold electrode is used as the working electrode, and the scanning speed is 10mV s -1 The open circuit potential of the solution was investigated, and the concentration of thiourea was determined by the volumetric method to investigate the change of the decomposition rate of thiourea in the two systems.

[0017] With Na 2 SO 3 、Na 2 SiO 3 Add slowly, 0.1mol·L -1 The initial open circuit potential of the alkaline thiourea solution drops from -0.2V to -0.25V and -0.29V respectively, and the solution can reach a steady state in about 500 seconds, the stable potentials are all -0.27V, and the decomposition rate of thiourea is 72.5%. With the addition of stabil...

Embodiment 2

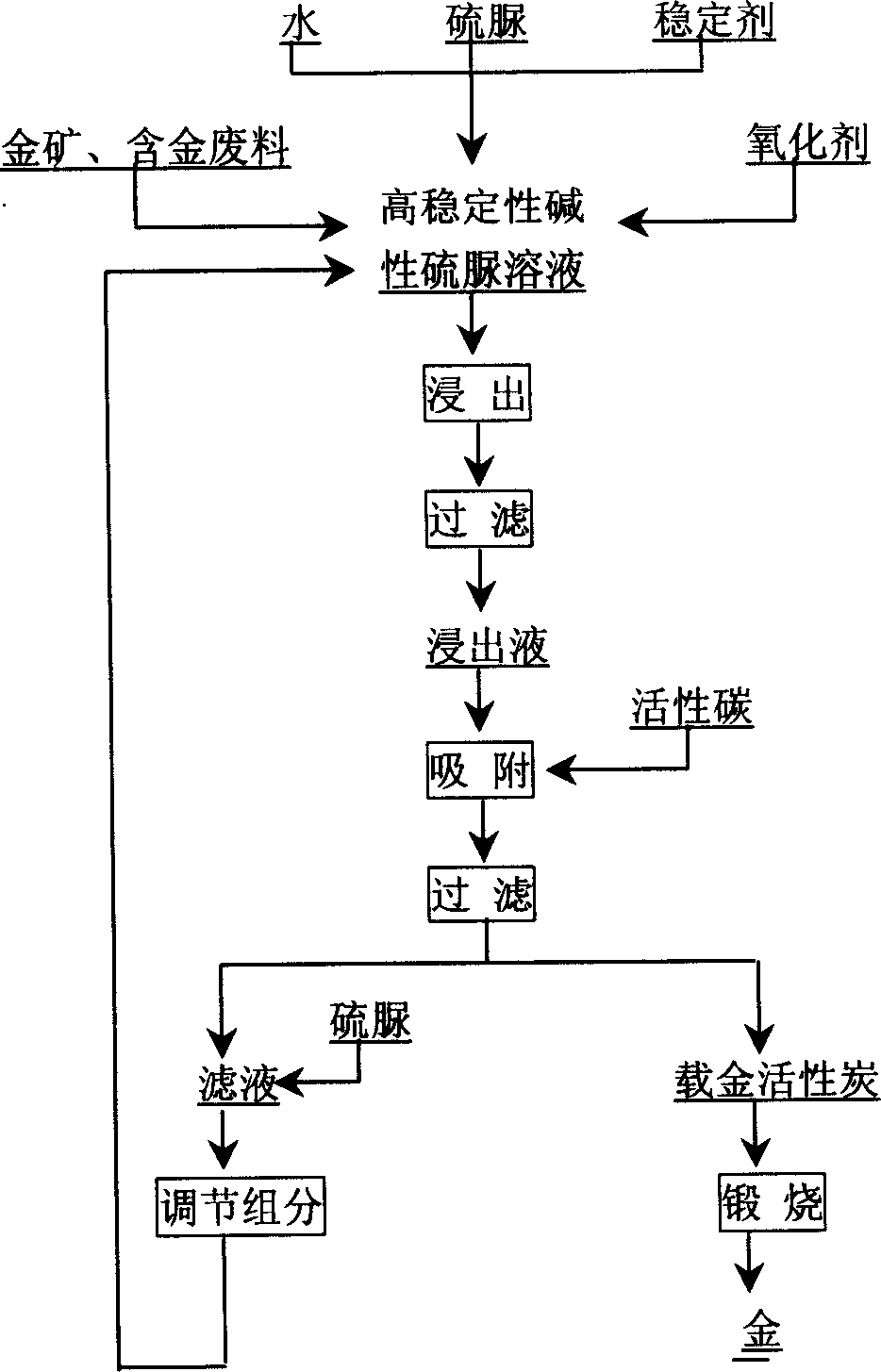

[0018] Embodiment 2: the immersion gold of high stability alkaline thiourea system

[0019] The raw material is oxidized gold ore after microbial treatment, and the main phase is SiO 2 , the gold content is 51.4g / t. The main steps of the leaching process are as follows:

[0020] First add a certain amount of water into the reaction kettle with air stirring and mechanical stirring, and add 0.25mol L in turn under the condition of mechanical stirring -1 Stabilizer Na 2 SiO 3 and thiourea 0.15mol L -1 , and mix evenly; pour a certain amount of oxidized gold ore into the reactor according to the solid-liquid ratio of 1:10, fully mix with the leaching solution, then add a metered amount of oxidant, and adjust the pH value of the solution to 12.5; stop the mechanical stirring, Start the air stirring, leaching at room temperature for 4 hours; after the reaction is completed, filter; the leaching solution is adsorbed by activated carbon, and the concentration of each component is...

Embodiment 3

[0021] Embodiment 3: the immersion gold of high stability alkaline thiourea system

[0022] The raw material is oxidized gold ore after microbial treatment, and the main phase is SiO 2 , the gold content is 51.4g / t. The main steps of the leaching process are as follows: First, add a certain amount of water to the reaction kettle with air stirring and mechanical stirring, and add 0.15mol L in turn under the condition of mechanical stirring -1 Stabilizer Na 2 SiO 3 and thiourea 0.15mol L -1 , and mix evenly; pour a certain amount of oxidized gold ore into the reaction kettle according to the solid-liquid ratio of 1:8, fully mix with the leaching solution, then add a metered amount of oxidant, and adjust the pH value of the solution to 12.5; stop mechanical stirring, Start the air stirring, leaching at room temperature for 4 hours; after the reaction is completed, filter; the leaching solution is adsorbed by activated carbon, and the concentration of each component is adjuste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com