Degradable chelate surfactant and producing method

A surfactant and production method technology, applied in chemical instruments and methods, dissolution, preparation of organic compounds, etc., can solve the problems of difficulty in accurately controlling the amount of ammonia added, reduced yield, inconvenient production and operation, etc. The effect of deposition, easy production control, strong complexing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

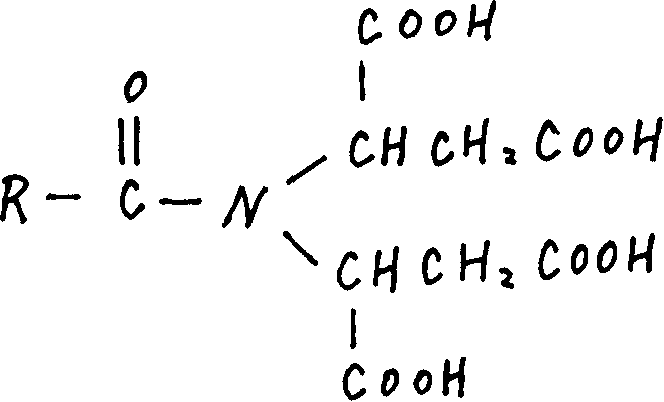

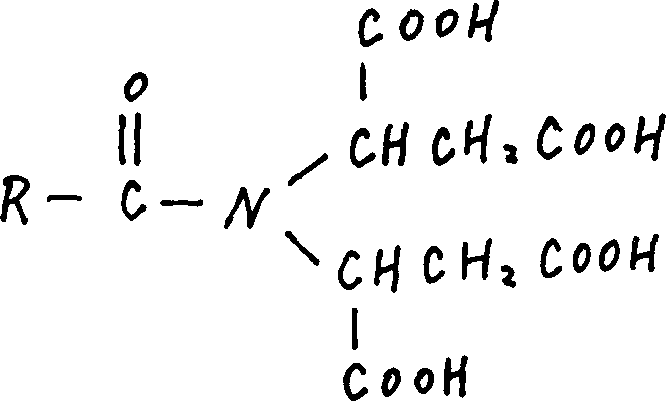

Image

Examples

Embodiment Construction

[0026] 1. Synthetic sodium iminodisuccinate

[0027] Add 1.96 kilograms of maleic anhydride and 2 kilograms of water to a 20-liter reaction kettle, and slowly add 0.8 kilograms of sodium hydroxide dissolved in 1.2 kilograms of water under the condition of stirring and cooling with water. Pay attention to control the addition of alkali during this alkali addition process Speed, do not make the temperature of the materials in the reactor exceed 60°C. After adding the lye, continue to stir for 5 minutes. At this time, the material is in a dry paste state with pH=2-3. Then add ammonium carbonate in batches, adding a total of 1.0 kg of ammonium carbonate. When adding ammonium carbonate, also pay attention to control the feeding speed to avoid carbon dioxide from taking out the material. After the addition of ammonium carbonate, the material was pasty with pH=7. Then slowly add 0.4 kg of sodium hydroxide dissolved in 0.6 kg of water to form a solution, after the addition, the material b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com