High-light-efficiency low-working-voltage gas discharging lamp-tube and mfg technology thereof

A gas discharge lamp, working voltage technology, applied in the direction of discharge lamps, discharge tubes, electrical components, etc., can solve the problem of little improvement in the inner surface of the glass bulb and the structure of the phosphor layer, and achieve the effect of reducing the driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

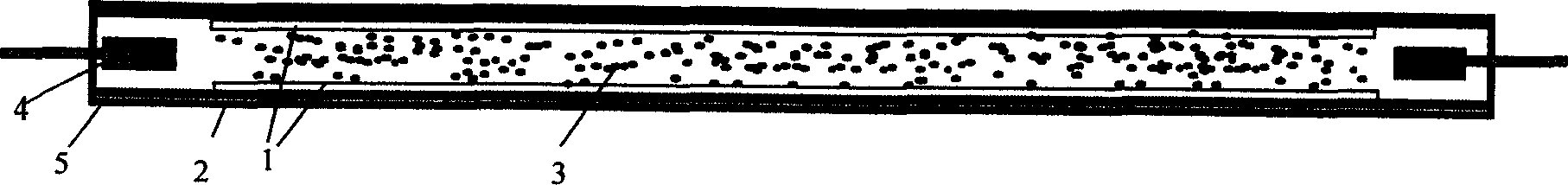

[0037] A cold-cathode fluorescent lamp with high luminous efficiency and low working voltage that can be used as a liquid crystal backlight source or lighting. It includes a lamp tube glass bulb 2 with both ends closed. Both ends of the tube glass bulb 2 are provided with internal cold electrodes 4 made of metals such as molybdenum, nickel, tungsten, etc., and the discharge gas 3 composed of neon, argon and mercury is filled in the lamp tube glass bulb 2, and in the lamp tube glass bulb 2 The inner surface is provided with a high secondary electron emission material dielectric layer 5, the above-mentioned high secondary electron emission material dielectric layer 5 is a magnesium oxide layer, an aluminum oxide layer or a magnesium aluminate layer, and the high secondary electron emission material dielectric layer 5 can also be other High secondary electron emission material, the glass bulb 2 of the above-mentioned lamp tube can be straight, curved, spiral or other shapes.

Embodiment 2

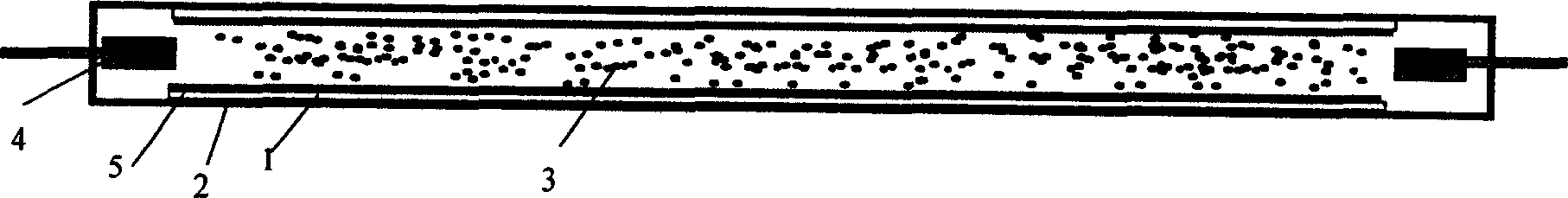

[0039] A fluorescent tube with high luminous efficiency and low working voltage external electrode that can be used as a liquid crystal backlight source or lighting. It includes a lamp tube glass bulb 2 with both ends closed. There are external electrodes 4 made of graphite on the outer surfaces of both ends of the tube glass bulb 2, and the discharge gas 3 composed of neon, argon and mercury is filled in the lamp tube glass bulb 2, and on the inner surface of the lamp tube glass bulb 2 A high secondary electron emission material dielectric layer 5 is provided on the top, and the above high secondary electron emission material dielectric layer 5 is a magnesium oxide layer, an aluminum oxide layer or a magnesium aluminate layer, and the high secondary electron emission material dielectric layer 5 can also be other high secondary electron emission material dielectric layers. Electron emission material, the glass bulb 2 of the above-mentioned lamp tube can be straight, curved, spi...

Embodiment 3

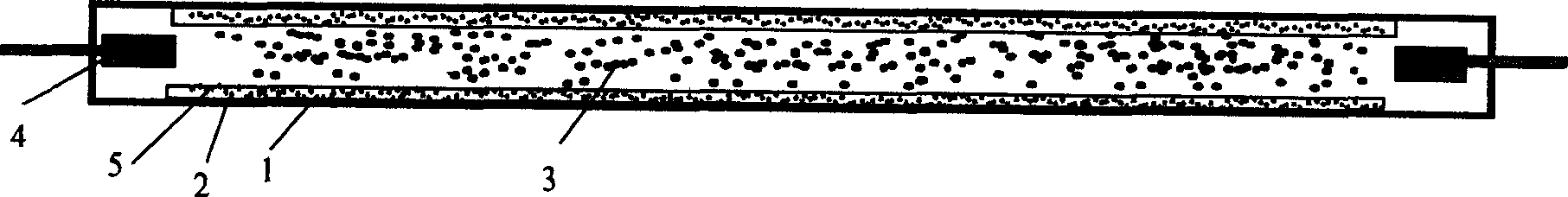

[0041] A preparation process for manufacturing the above-mentioned high-luminous-efficiency low-voltage external-electrode fluorescent lamp tube: take the cleaned and dried glass bulb of the lamp tube with both ends open, mix magnesium acetate and an organic solvent on its inner surface to form a slurry and coat it Baking is carried out, magnesium acetate and organic solvent are decomposed, and the generated magnesium oxide dielectric layer is attached to the inner surface of the glass bulb, and then a phosphor layer 1 is arranged on the inner wall of the bulb bulb of the lamp tube to seal one end of the bulb bulb of the lamp tube, The other end is sealed with a glass exhaust pipe. The gas in the pipe is discharged through the exhaust pipe and filled with discharge gas. Graphite milk is used to make discharge electrodes, which are used as external electrodes after being baked. The glass bulb of the above-mentioned lamp tube can be straight, curved, spiral or other shapes, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com