Process for preparing organic and inorganic composite film by autoassembling tech

A technology of inorganic composite membrane and self-assembly technology, which is applied in the field of organic-inorganic composite membrane prepared by self-assembly technology, can solve the problems of high cost and unsatisfactory membrane permeability, and achieves high controllability, excellent pervaporation separation performance and process. Simple and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

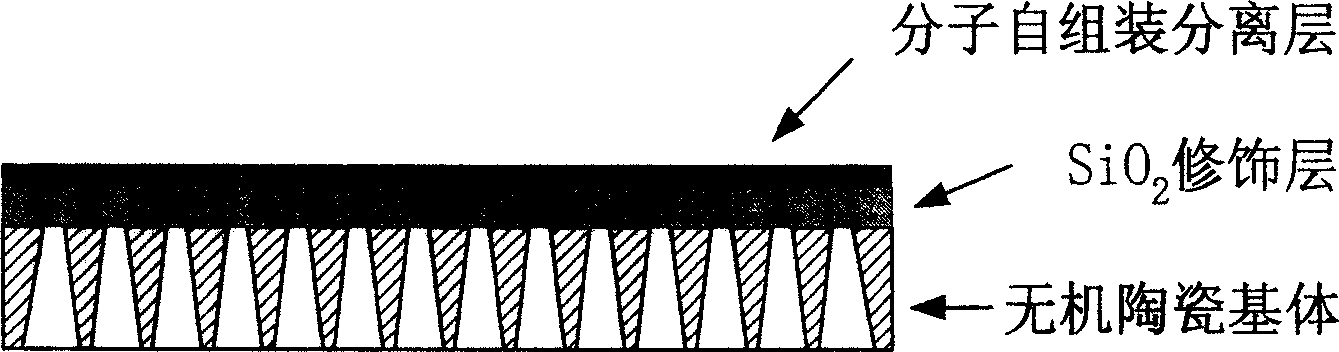

[0023] Preparation of organic-inorganic composite membrane

[0024] A mixture of 50ml of tetraethyl orthosilicate, 50ml of absolute ethanol, 30ml of deionized water, and 5ml of nitric acid was placed in a water bath at 60°C and refluxed for 2 hours to obtain a silica sol, which was sealed and aged in an oven at 25°C.

[0025] The prepared silica sol was coated on Al 2 o 3 The inner side of the porous ceramic membrane tube is dried in an oven at 25°C for 3 days, and then fired at 500°C for 4 hours, then the inner side of the ceramic membrane tube is coated with SiO 2 The membrane layer was washed alternately with acetone, ethanol, and deionized water, and repeated washing 5 times, and then in pure N 2 Blow dry in air.

[0026] Add hydrochloric acid to polyallyl ammonium chloride to prepare a cationic solution, wherein the concentration of polyallyl ammonium chloride is 0.01mol / L, and the concentration of hydrochloric acid is 0.01mol / L. Add hydrochloric acid to sodium polyst...

Embodiment 2

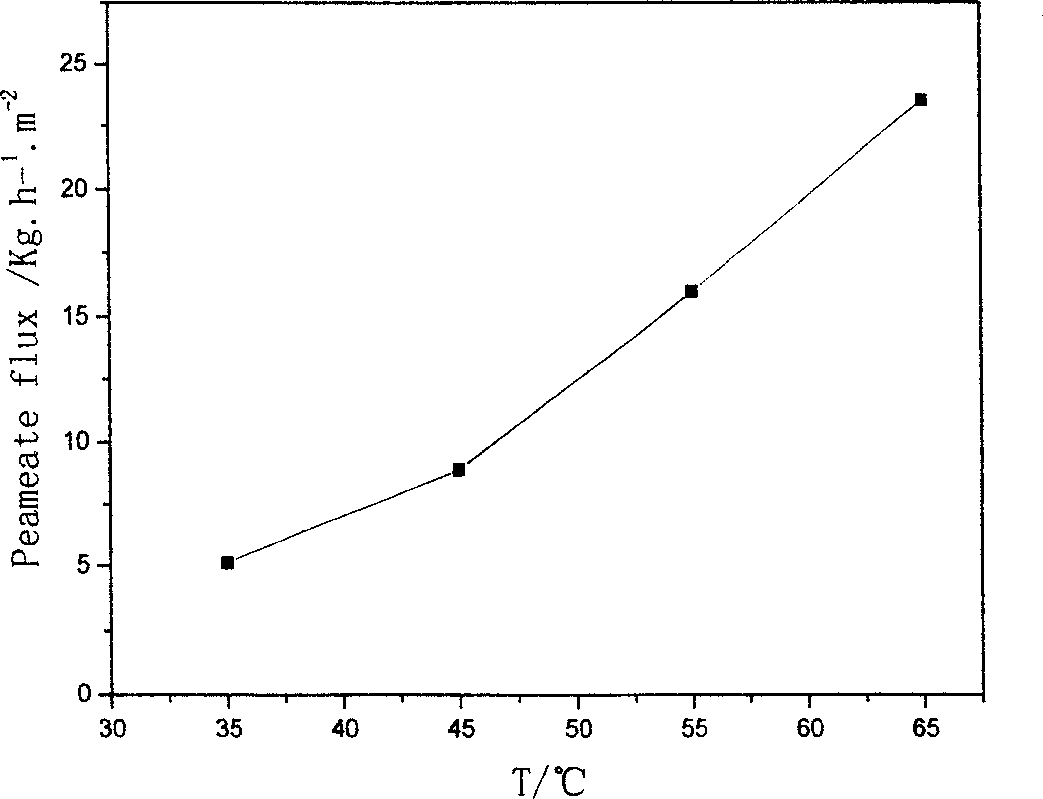

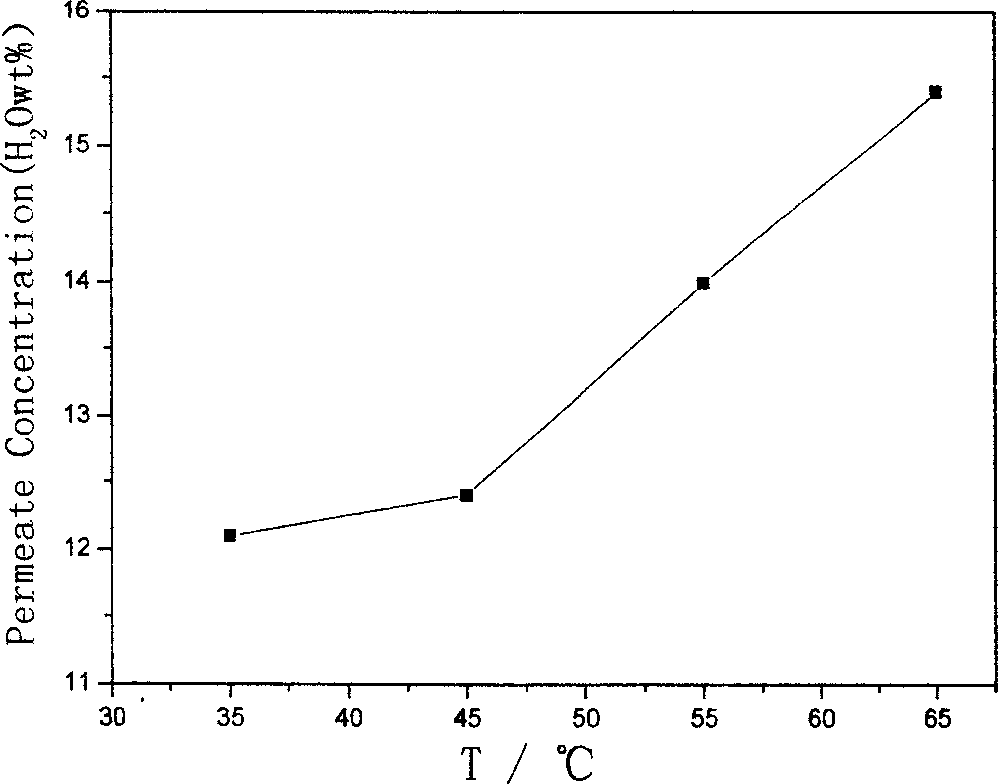

[0029] Pervaporation performance test of composite membrane in the above example

[0030] On the self-made pervaporation experimental device, carry out the separation research of the ethanol / water mixture of composite membrane, raw material ethanol weight concentration is 95% (being water content 5%), and osmotic measuring pressure is 500Pa, and experimental result is as follows figure 2 and image 3 .

[0031] image 3 It can be seen that the water content of the raw material solution increases from 5% to 16% on the permeate side, and the composite membrane preferentially permeates water, thereby further concentrating the ethanol in the raw material solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com