Yellow electronic ink microcapsule preparation method

A yellow electronic and microcapsule technology, applied in inks, household appliances, applications, etc., can solve the problems of insufficient capsule strength, poor capsule transparency, long reaction time, etc., and achieve good environmental stability, good geometry, and easy availability of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

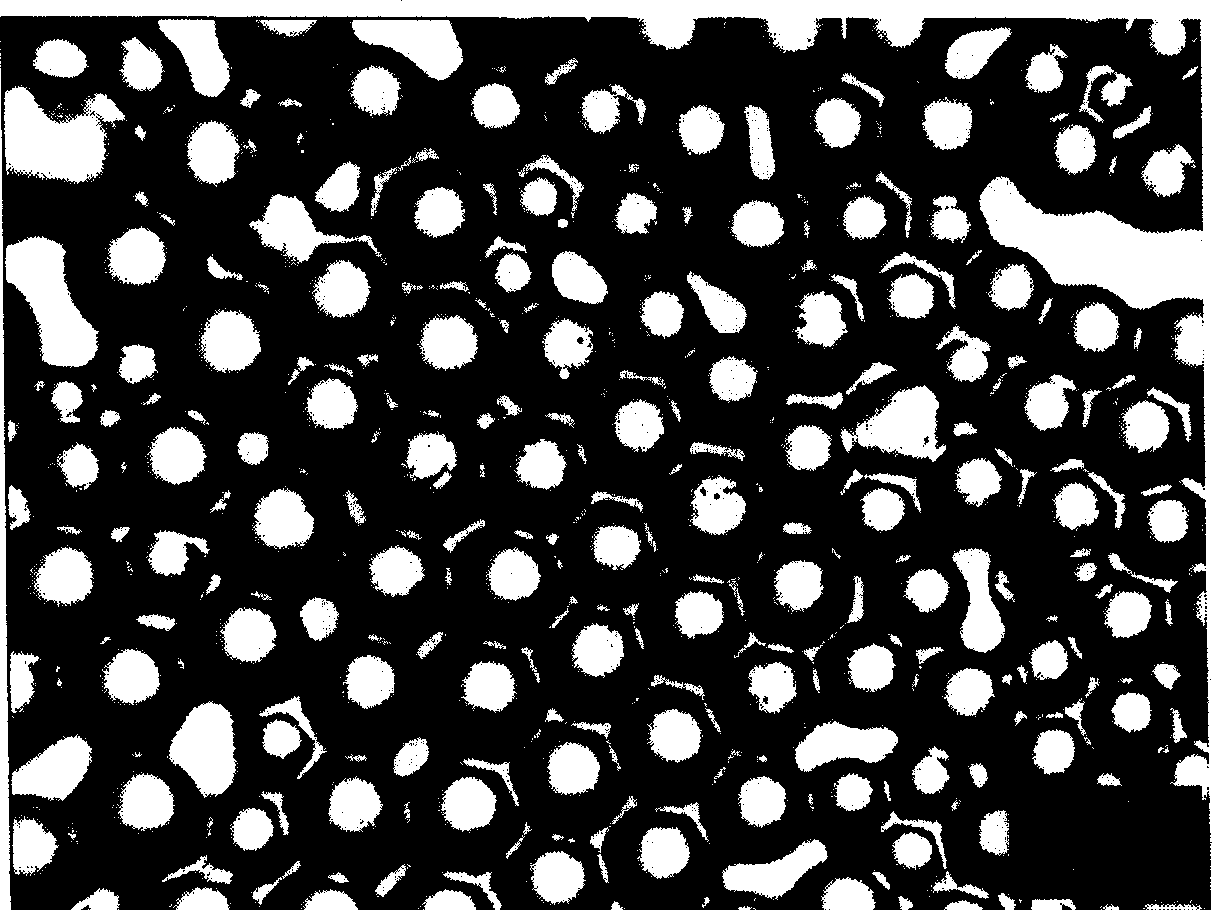

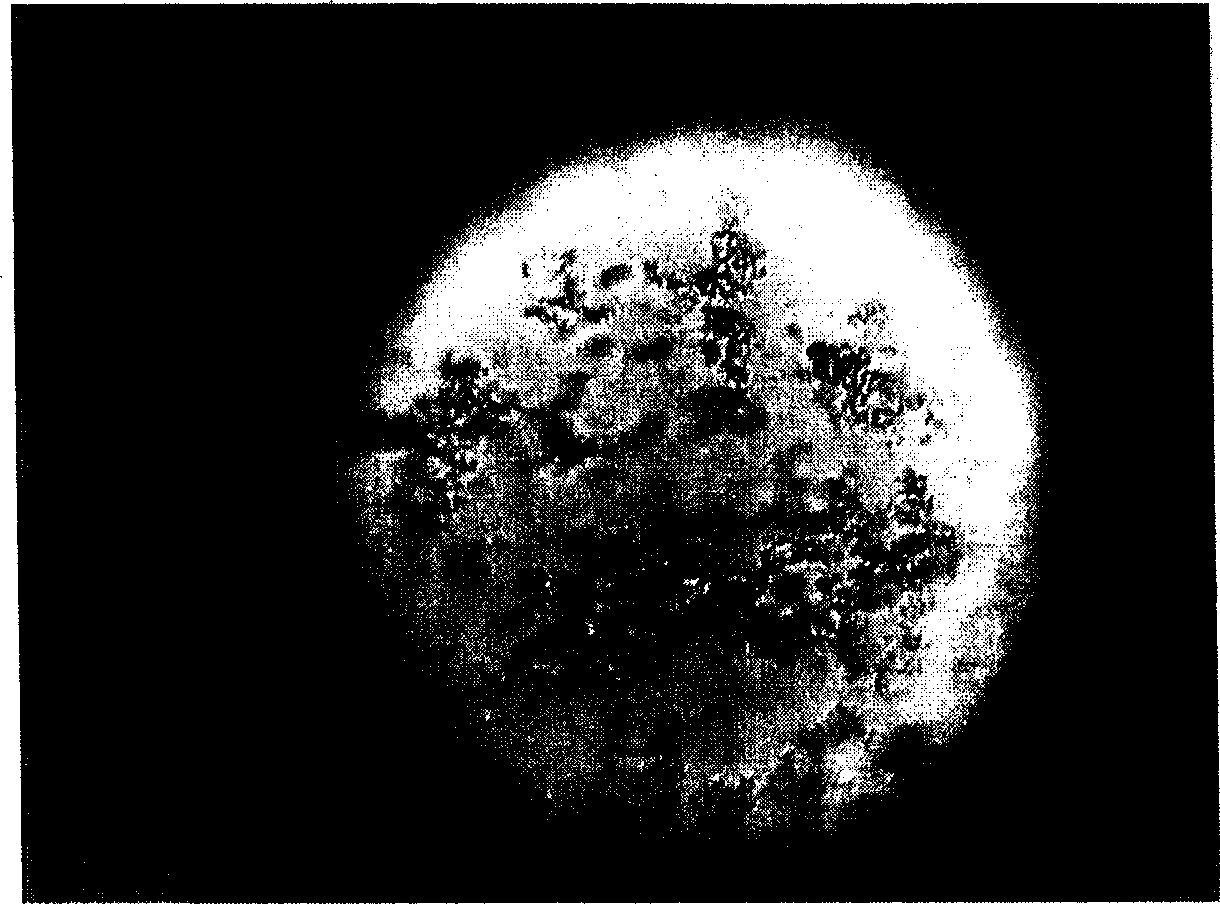

[0014] Take 20mL of tetrachlorethylene, add 0.1g of Hansa yellow 10G to it, add 0.1g of OP-10, 0.1g of didecyldimethylammonium bromide, add 30g of glass beads, grind for 4 hours at 300rpm, and then Remove the glass beads by filtration to obtain a stable and dispersed yellow electrophoresis solution.

[0015] Take 4mL of the above-mentioned yellow electrophoretic solution, add 0.23g of terephthaloyl chloride into it, and stir to dissolve it completely; add 40mL of distilled water to a 100mL three-neck flask, add 2.04g of diethylenetriamine, stabilize the stirring speed at 800rpm, add The electrophoretic solution containing terephthaloyl chloride was reacted for 1 minute, the stirring rate was reduced to 400 rpm, and the stirring was stopped after 10 minutes, and the yellow electronic ink microcapsules were obtained by suction filtration, washing with deionized water, and drying at room temperature.

example 2

[0017] Take 20mL tetrachlorethylene, add 0.2g Hansa yellow 10G to it, add 0.05g OP-10, 0.05g didecyldimethylammonium bromide, add 20g glass beads, grind for 4 hours at 300rpm, then Remove the glass beads by filtration to obtain a stable and dispersed yellow electrophoresis solution.

[0018] Take 4mL of the above-mentioned yellow electrophoretic solution, add 0.32g of toluene diisocyanate into it; add 40mL of distilled water to a 100mL three-necked flask, quickly add the above-mentioned electrophoretic solution containing toluene diisocyanate, start stirring to stabilize the speed at 800rpm for a period of time, then add 1.44 g polyvinyl alcohol 6000 10mL aqueous solution, after reacting for 10 minutes, reduce the stirring rate to 400rpm, stop stirring after 30 minutes, filter with suction, wash with deionized water, and dry at room temperature to obtain yellow electronic ink microcapsules.

example 3

[0020] Take 20mL of tetrachlorethylene, add 0.1g of Hansa yellow 10G to it, add 0.1g of OP-10, 0.1g of didecyldimethylammonium bromide, add 30g of glass beads, grind for 4 hours at 300rpm, and then Remove the glass beads by filtration to obtain a stable and dispersed yellow electrophoresis solution.

[0021] Take 4mL of the above-mentioned yellow electrophoretic solution, add 0.32g of toluene diisocyanate into it; add 40mL of distilled water to a 100mL three-necked flask, quickly add the above-mentioned electrophoretic solution containing toluene diisocyanate, start stirring to stabilize the speed at 800rpm for a period of time, then add 1.46 g triethylenetetramine 10mL aqueous solution, after reacting for 5 minutes, reduce the stirring rate to 400rpm, stop stirring after 15 minutes, filter with suction, wash with deionized water, and dry at room temperature to obtain yellow electronic ink microcapsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com