Organic / macromolecule top emission light-emitting device and its application

A light-emitting device and top-emission technology, which is applied in the direction of organic semiconductor devices, semiconductor/solid-state device manufacturing, and luminescent materials, can solve the problems of complex manufacturing process and easy damage to the light-emitting layer, and achieve simple manufacturing process, good environmental stability, The effect of high quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

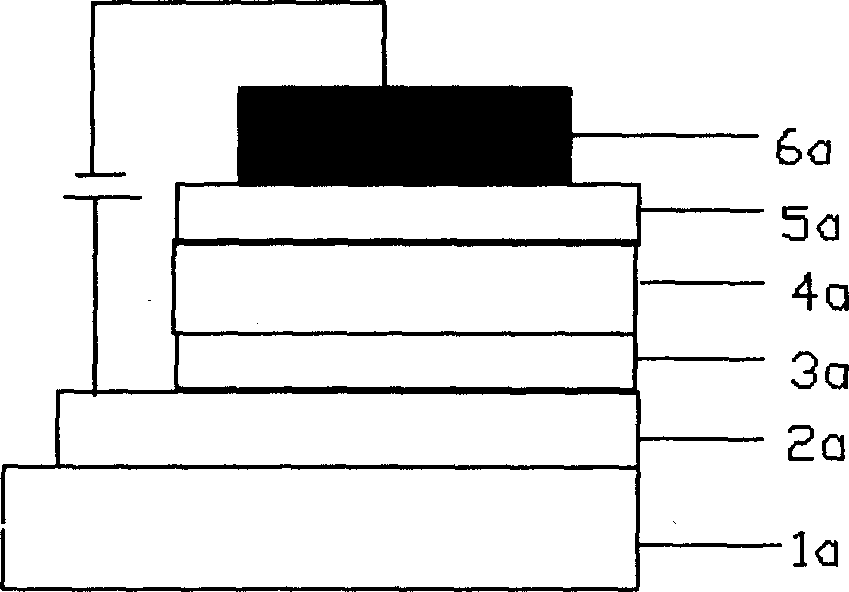

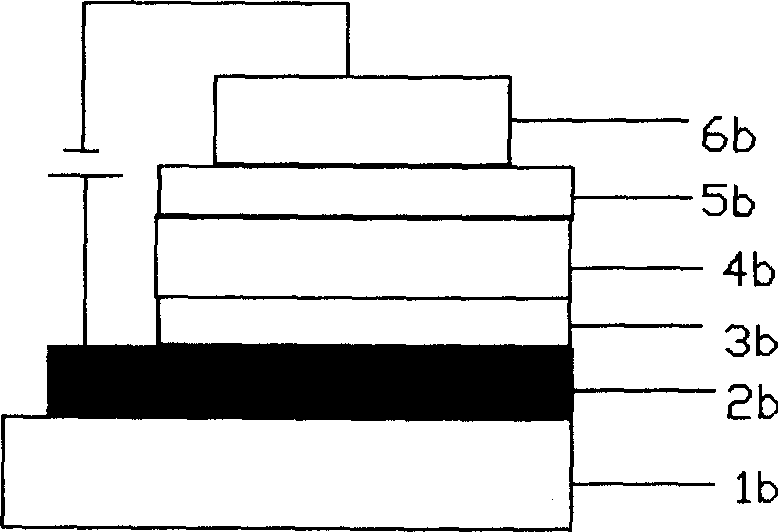

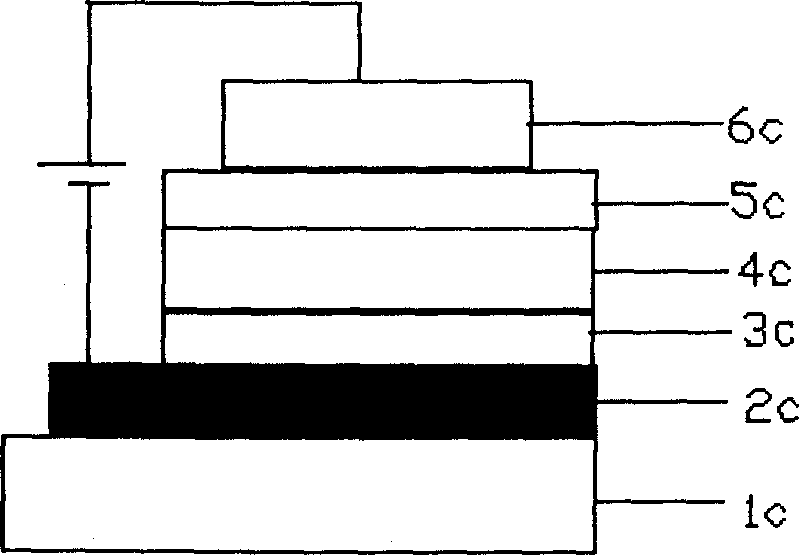

Method used

Image

Examples

Embodiment 1

[0062] ITO conductive glass, sheet resistance ~ 20Ω / □, or ordinary glass without ITO, pre-cut into 15mm×15mm square pieces. Sequentially use acetone, special detergent for micron semiconductors, deionized water, and isopropanol to ultrasonically clean, nitrogen purged, then placed in a constant temperature oven for standby, and further processed in an oxygen plasma cleaner before use.

[0063] After weighing the fluorescent conjugated polymer in a clean bottle, transfer it to a nitrogen-protected film-forming glove box (VAC company), dissolve it in toluene, and filter it with a 0.45 micron filter membrane. The optimal thickness of the polymer light-emitting layer is 70-90 nanometers. The film thickness was measured with a TENCOR ALFA-STEP-500 surface profiler. PFNBr-BTDZ05, PFN-BTDZ05, PF-N + R 3 , PF-NR 2 Dissolve them in methanol respectively, and prepare three solutions with concentrations of 0.02%, 0.1%, and 0.2%. Use the uniformly glue machine to rotate the pre -stea...

Embodiment 2

[0082] Repeat Example 1, but the polymer light-emitting layer is replaced by green light-emitting phenyl-substituted poly-p-phenylene vinylene (P-PPV), and the electron injection layer uses PFNBr-BTDZ05 or neutral precursor PFN-BTDZ05 respectively. The experimental results are summarized in Table 6 and Table 7, respectively.

[0083] Table 6 is based on the green light material P-PPV, using aluminum as the cathode, using gold as the transparent anode, and using

[0084] Emissive

Thickness

()

A node

(V)

Current

(mA)

Luminance

(cd / m2)

QE

(%)

P-PPV

P-PPV

P-PPV

50

100

200

Al

Al

Al

Au

Au

Au

24.2

26.5

30

12.6

29.1

3.61

155

2738

128

0.16

1.2

0.45

[0085]The top-emitting light-emitting device structure in Table 6 is ITO / Al / PFNBr-BTDZ05 / P-PPV...

Embodiment 3

[0093] Repeat Example 2. The polymer light-emitting layer was replaced by polyfluorene (PFO) that emits blue light, and poly[9,9-dioctylfluorene-9,9-bis(N,N-dimethylaminopropyl)fluorene] A three-component copolymer with a narrow band gap (narrow band gap monomer benzothiadiazole) (PFN-BTDZ05) was used as the electron injection layer. The experimental results are summarized in Table 8. Figure 9(a) is a graph of voltage-current-luminescence luminance of a top-emitting light-emitting device using PFN-BTDZ05 as the electron injection layer, blue-emitting polyfluorene (PFO), aluminum as the cathode, and gold as the transparent anode. Fig. 9(b) is the electroluminescence spectrum of the top emission light-emitting device.

[0094] Table 8 is based on the blue light material PFO, using aluminum as the cathode, using gold as the transparent anode, and using PFN-BTDZ05

[0095] Emissive

Thickness

()

A node

Voltag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com